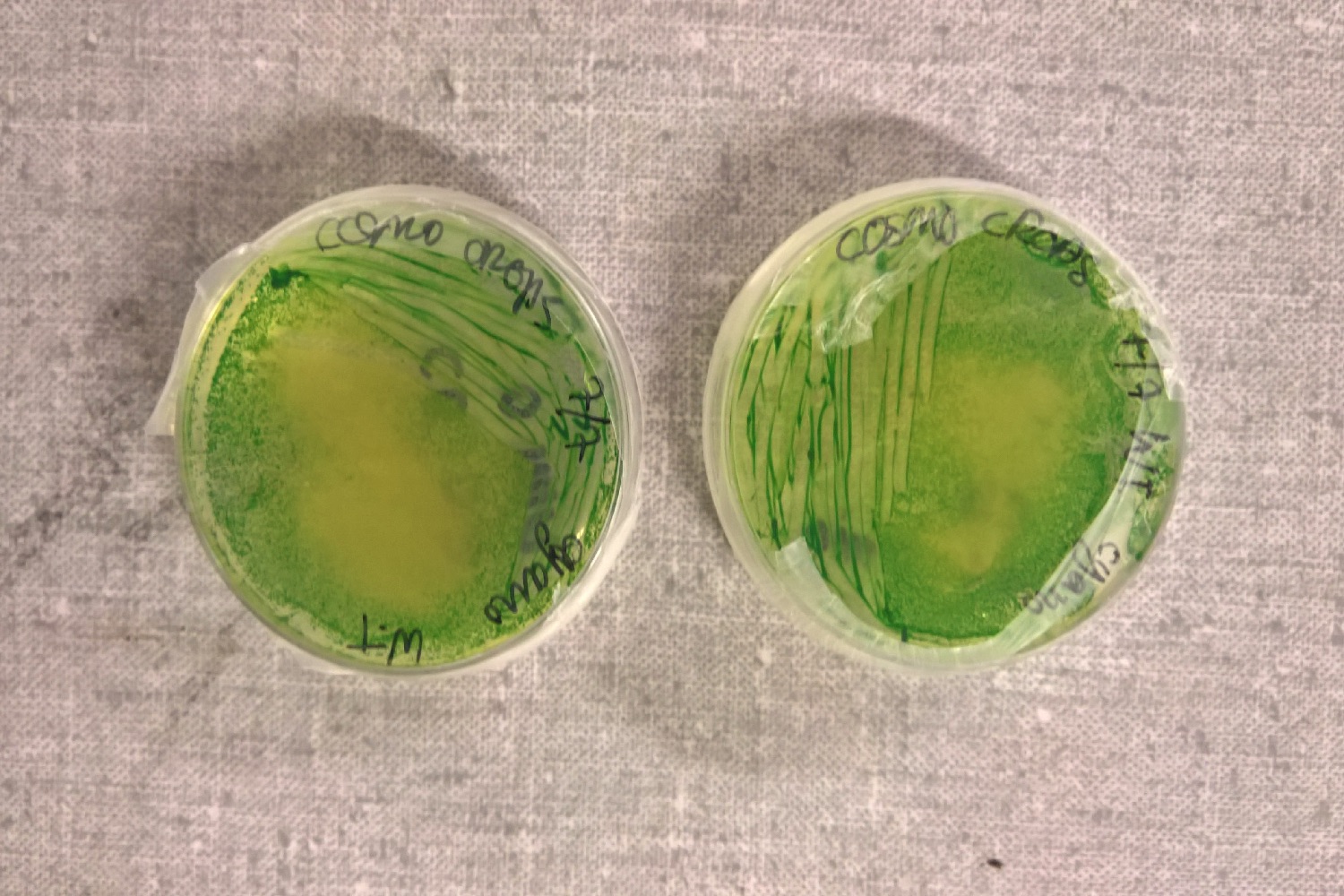

That’s where a group of Danish researchers comes in. The team is working on a synthetic biology project called CosmoCrops, which hopes to use bacteria to make it possible to 3D print everything needed for a respectable space mission, using a cutting-edge co-culturing system. And it could even make life better for those of us back on Earth in the process.

“We are trying to make space exploration cheaper, because many inventions we use in our daily life were invented because of space exploration, like Velcro and solar energy,” Joachim Larsen, one of the students working on the project, told Digital Trends. “The way we want to achieve this is to [be] able to produce everything from food to medicine and bioplastic for 3D printers out in space — making the space rocket a lot lighter.”

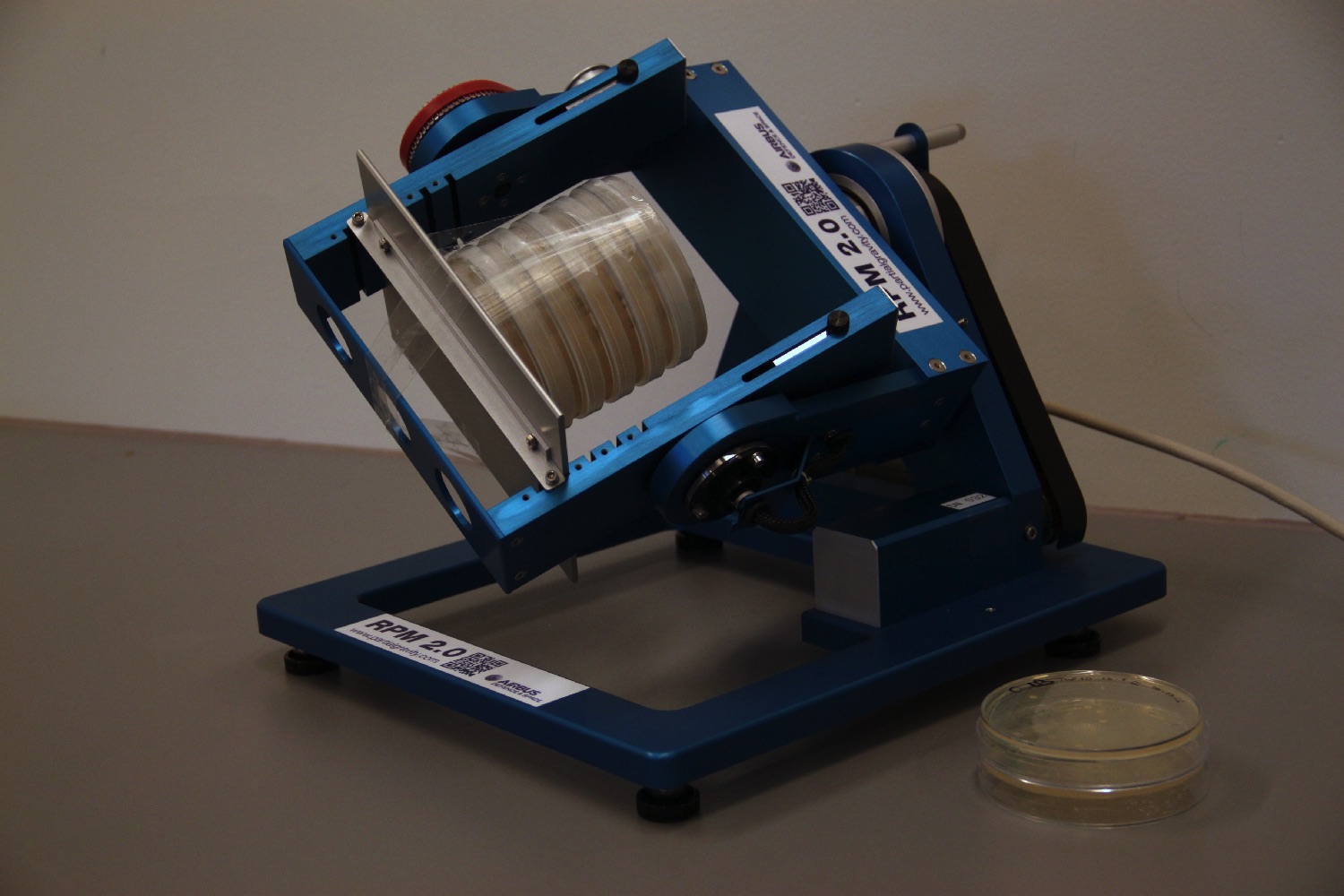

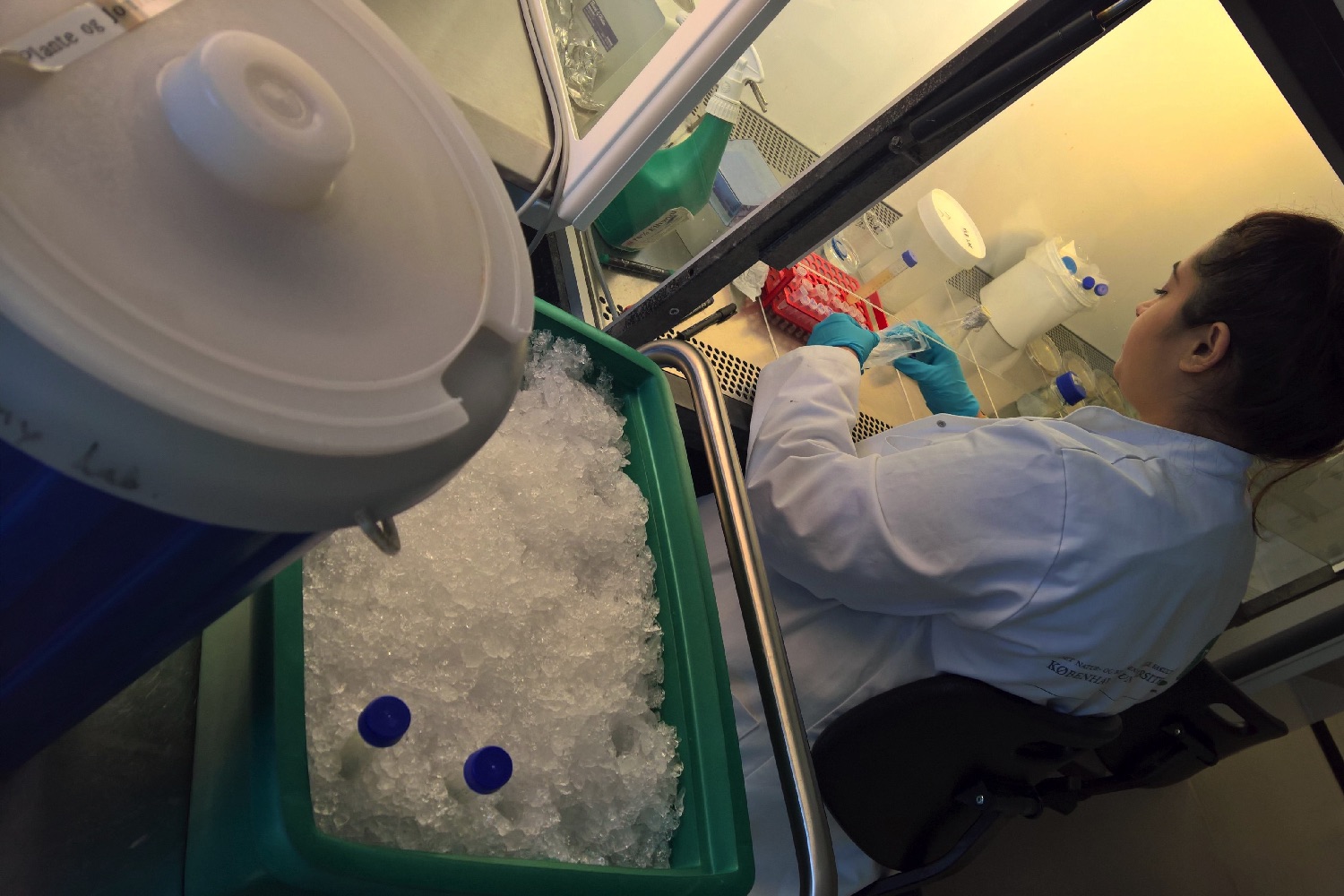

To this end, the team has designed a special kind of bioreactor and has bioengineered bacteria that can be used to produce the necessary 3D-printing materials.

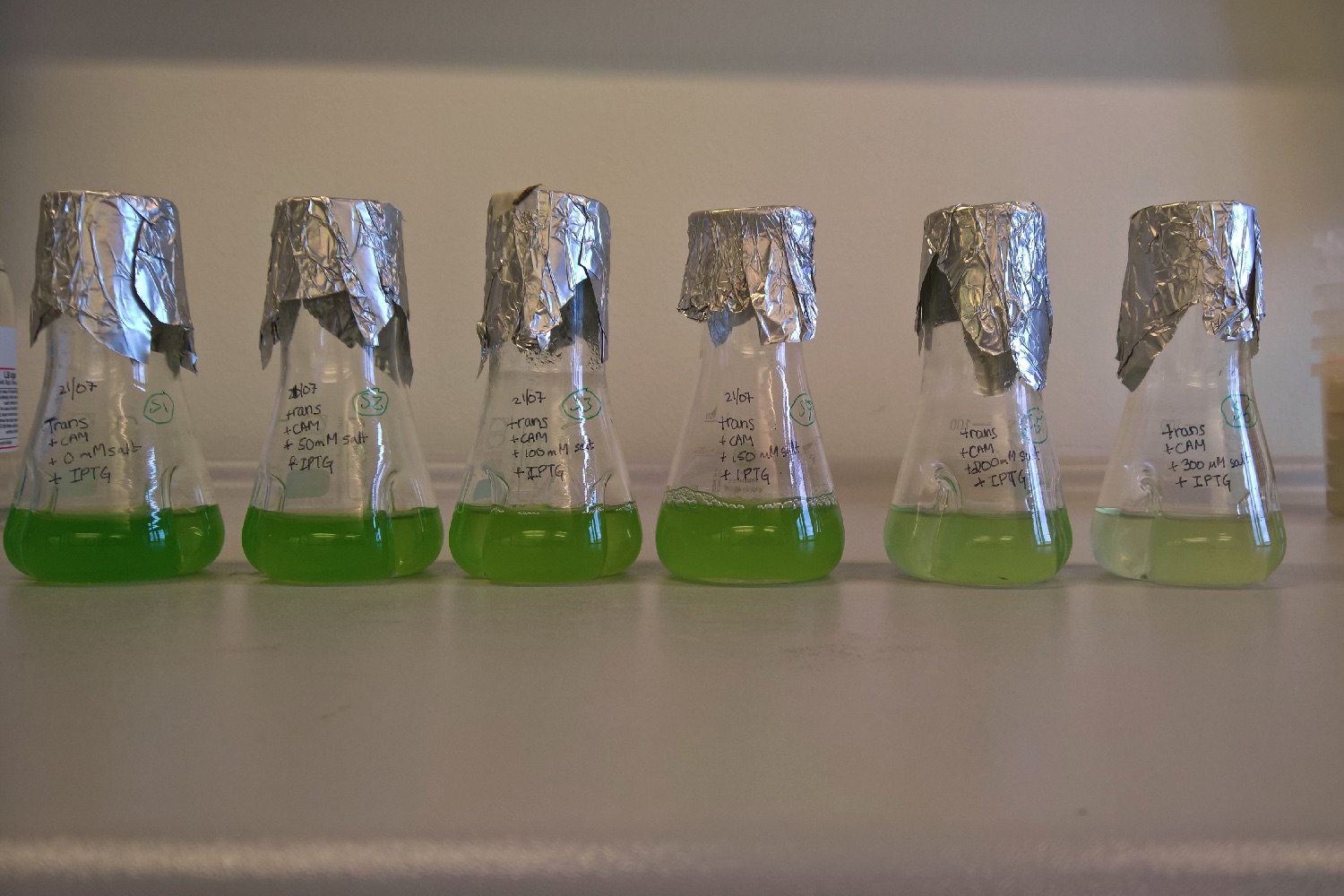

“In the bioreactor we take advantage of the ability of cyanobacterium to produce sugar from the sunlight and the CO2 found in the air,” Larsen continued. “This sugar is secreted and used by a genetically engineered B. subtilis that can produce [a] bioplastic that can be used in 3D printers.”

If that sounds a bit complex, then consider that the goal is to make something as durable as possible. As Larsen said, “we are producing a ‘super-bacterium’ that can survive out in space.”

The bacteria was chosen because of its ability to make spores, which are inactive forms of the organism that can survive in a powder form without any form of nutrition or energy. The bioreactor itself is also optimized to survive in the hostile environment found in space, and specifically on Mars.

“By exposing the organisms to different parameters, such as high radiation, low temperature, or low pressure, mutations will be induced and [will] make the organisms able to survive,” Larsen continued.

Right now, we’re certainly not at the point of being able to transport essentials to space in the form of powder that can later be deposited in a Petri dish to create anything from a hamburger to a space spanner. But Larsen said that we should expect to see significant developments in the next several years, rather than decades.

A work-in-progress version of a functioning co-culture system is set to be shown off next month, after which a demonstration of bacteria capable of surviving in space conditions is set to follow in 2018.

It’ll be a bit longer than that before you’re able to 3D print your own seasoned space steak, however. But, if you’ll excuse the pun, keep watching this space.