Fortunately, a new piece of research from Syracuse University biomedical and chemical engineering PhD candidate Bendy Estime suggests a new method may be on the horizon.

“This research proposes an energy efficient way to grow and harvest microalgae,” Estime told Digital Trends. “By allowing microalgae to grow in a confined environment, mixing cost can be avoided and the distribution and absorption of light can better be controlled. The simplification of the microalgal biomass harvesting process makes this technology even more outstanding.”

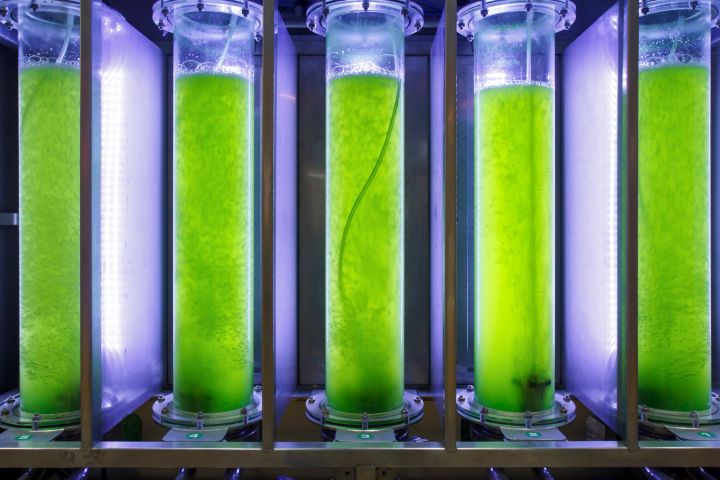

Estime’s work addresses several bottlenecks with microalgae cultivation. These include its tendency to stick to the walls of containers, therefore blocking out necessary light needed for growth; the constant need for stirring to make sure that light reaches the right places; and the final, time-consuming task of separating the algae from the “broth.”

To solve all of these in one fell swoop, Estime has developed a new growth medium called Tris-Acetate-Phosphate-Pluronic (TAPP). What is neat about TAPP is that it can transition from a solution to a gel with relatively minute variations in temperature.

When the microalgae is first seeded, it’s kept at 15 degrees celsius, which makes it a solution. When it’s heated by just 7 degrees, it becomes a gelatinous mixture in which microalgae grows in clusters 10x larger than in the regular medium. Finally, it’s cooled again for harvesting, at which point it turns back into a solution, which can be separated using gravity.

According to Estime, the system could result in microalgae being harvested at 10x the speed of traditional systems, and in a manner that is highly energy-efficient. (Dare we say it, even “green.”)

“This technology will have primary applications in large scale microalgal biomass production for bioenergy production or pharmaceutical and nutraceutical applications,” he said. “But it can also find further applications in other fields such as biofouling control.”