While many outdoor gear companies are working to advance the technology we use outside, Mountain Safety Research stands out from the crowd thanks to its focus on lightweight and technical equipment. Seattle-based mountaineer Larry Penberthy started the company as a newsletter in 1969, offering information on mountaineering safety and funded it by selling third-party gear. In 2001, Cascade Designs acquired MSR from REI and since then, the company’s made the backcountry safer with a growing line of products and gear.

Today, the brand continues to make strides in the outdoor industry with the development of, among others, efficient cookstoves, backcountry tents, snowshoes, and trekking poles. Every product is designed for a specific purpose, utilizing the best technology on the market — after all, research and development has always played a vital role in the company’s ethos.

For the past few decades, MSR’s extended its reach beyond consumer-focused gear by creating technologies for global health and disaster relief. To see first hand the innovation occurring throughout MSR and its labs — and to do a little hands-on testing of its products — Digital Trends joined the brand for a tour of its headquarters in Seattle, Washington.

Building a better tent

One of the biggest issues tent manufacturers encounter is deciding on the kind of coating to use to make a product waterproof. Traditional tents for camping, backpacking, and mountaineering are all crafted from nylon but the difference is in the coating. Many companies utilize urethane, including many of MSR’s biggest competitors. The problem? When urethane coating stays damp or wet — especially in hot or humid areas — it degrades and turns gummy over time.

“We’ve been actively working on a better version of this for ten years,” Terry Breaux, MSR’s tent category manager, told Digital Trends. “We finally have a new coating — called Xtreme Shield — where you can see comparatively why it’s better. We feel it’s three times better than a normal coating but the challenge we have is reproducing its failure in the lab — to replicate ten years of use. After two years of research, we started using an Australian military test featuring accelerated hydrolysis testing.”

It’s one thing to make a claim but another to actually prove it. During the tour, we cut samples from a variety of tents, some of which included Xtreme Shield, while others were built using the company’s other proprietary coating, Durashield. MSR even had a few competitors on hand for comparison. In the lab, we experimented with the samples by submerging the fabric into a caustic solution which essentially speeds up the aging process. The results were astounding — not only did Xtreme Shield prove to withstand higher hydrostatic pressure after “aging”, but it also showed significantly less degradation.

The Xtreme Shield difference

Flashy moniker aside, Xtreme Shield is a different formulation of urethane that’s not typically used in the camping industry. Though MSR wouldn’t reveal its specific recipe, the brand did tell us they refer to it as the ‘Secret Sauce’. Xtreme Shield is featured on each of MSR’s newest backpacking tents, including the Hubba Tour 3, which recently won Outside Magazine’s Summer Buyer’s Guide Gear of the Year award.

“The other problem with tents is the seam tape,” Breaux added. “It corrodes over time, so we’ve worked on how to make a tent waterproof without using seam tape. We’re using hydrophobic cotton woven with polyester that swells when wet. The customer is going to look at a tent without seam tape and worry they’re going to get wet because they’ve seen it on tents for years — but real-world testing proves this is not the case.”

A stronger structure

As it continues to stress-test Xtreme Shield, MSR also intends to reinvent the tent pole. The brand knows the perfect tent pole is one that’s both flexible and very strong. Unfortunately, those two features don’t always go hand in hand. Instead of using carbon fiber — i.e. One of the lightest and stiffest materials on the planet — MSR wanted something which provided a bit more flexibility. Its answer was the Easton Syclone poles.

Syclone poles are far more flexible than aluminum or carbon, and 80 percent less likely to fail beneath the force of strong winds.

Unlike aluminum and carbon poles which bend or snap under enough pressure, Syclone poles are built with composite materials wound from multiple directions into a tube, allowing them to flex under force and return to shape. They’re far more flexible than aluminum or carbon, and 80 percent less likely to fail beneath the force of strong winds. They’re also as light as aluminum.

“Where the Sylcone wins is in the tensile strength category,” Breaux said. “The question to ask is how far can you stretch it until it fails. So we introduced the Syclone poles in 2017 in our all-season winter tents, where you want that extra level of security. You can actually flatten your tent to the ground and it pops back up. During testing, we tried to make it fail — but we couldn’t.”

To prove this final point, Breaux first demonstrated the breaking point of aluminum and carbon fiber, both of which snapped under enough pressure. He then flattened one of MSR’s tents featuring Syclone poles all the way to the ground and it immediately snapped back up, its shape completely retained. While the company’s goal isn’t to encourage mistreatment of its products, testing proves Syclone poles won’t let you down.

“We envision this is the future of tent poles,”Terry Breaux told Digital Trends.

Changing the world

There’s no doubt MSR’s building momentum in the outdoor industry but it’s also helping with disaster relief and working to improve global health. Currently, there are six technologies on the company’s blog which serve to outline these efforts. One such initiative is the “the toilet of the future,” which would be a low-cost, practical, and culturally acceptable option in developing countries. Others include the development of an automatic chlorine doser for safe tap water, an individual desalinator to create drinking water from the ocean, a treatment to remove the chlorine taste from purified water, and a low-cost hand washing station for remote communities.

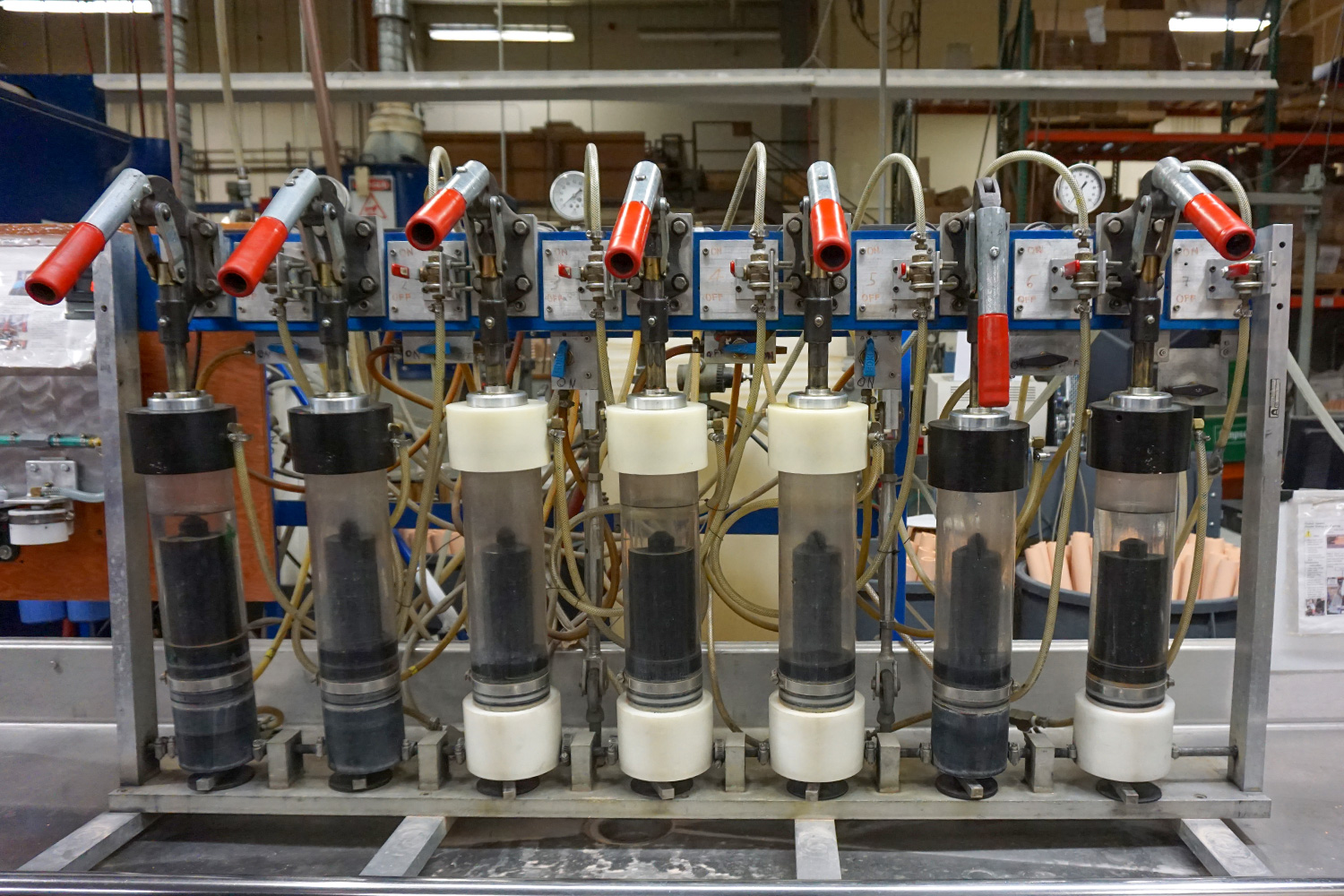

The SE200 Community Chlorine Maker creates chlorine with the push of a button to make safe, drinkable water.

Its highlighted project is rooted in helping provide safe drinking water to people in low-resource countries, while also providing access to safe water in health facilities. At the heart of the program is the company’s SE200 Community Chlorine Maker, a device that’s already reaping positive benefits for MSR and the communities it’s helped. So, why has an outdoor gear company taken such an avid interest in global health?

“Why bridge over to the developing world?” asked Patrick Diller, who represents the company’s Global Health division. “It started about 10 to 15 years ago when a major tsunami hit Asia and many internal employees saw this as an opportunity to help. We’ve always manufactured water treatment devices and tech, so we decided to provide them to those in need. However, our first attempt to help was a disaster. We learned you can’t just take an outdoor product and drop it into any market and expect it to work — especially in a developing world. So we developed the SE200 to answer those challenges we had.”

The SE200 Community Chlorine Maker creates chlorine with the push of a button to make safe, drinkable water. The device produces chlorine from the combination of water, salt, and any power source and takes those molecules apart and puts them back together, resulting in chlorine and hydrogen byproducts.

“It really solves supply chain issues by empowering communities to make their own chlorine on the spot,” Diller added. “You can run this every three to five minutes and with each batch, you’re creating enough chlorine to purify 200 liters of water capable of serving a community of about 200.”

In 2017, the MSR Global Health Team made its biggest impact upon the world by providing safe drinking water to more than 250,000 people in over 30 countries. Much of this impact was done via its Community Chlorine Maker, which is quickly becoming the company’s flagship product for global health. MSR teamed with World Vision to provide these products for use in health facilities in remote regions and aside from water treatment, chlorine is great for surface sanitation, disinfecting linens, cleaning wounds, and many other infection-preventing measures.

The outdoor industry is unique in that it’s passionate about nature, conservation, and its participants — and this passion translates into a greater goal: Helping to make the world a better place. While MSR isn’t the first company to take its extensive knowledge of outdoor products and implement it into life-saving applications, it’s certainly had a powerful and recognizable impact. Mountain Safety Research serves as a flagship company the outdoor industry should be immensely proud of — and one it should strive to emulate.