3D printing made some big advances in the medical domain last year, and it seems like that trend isn’t going to slow down any time soon. Proving that point is an impressive procedure recently carried out in Bulgaria, in which a patient received one of the first 3D-printed ribs as part of a potentially lifesaving operation. It demonstrated a new approach to create rib implants, using a process called fused deposition modeling (FDM), which is cheaper in both machine and material costs than other similar attempts.

“[The] patient, Ivaylo Josifov, was diagnosed with a rib deformation,” Mateusz Sidorowicz, director of marketing at 3DGence, the company which made the 3D printer, told Digital Trends. “The doctors were concerned that the deformity may progress, and decided to replace the rib with an implant. Unfortunately, traditional implants — made from titanium, for example — are very expensive. Also, the titanium itself is not a perfect material for replacing ribs.”

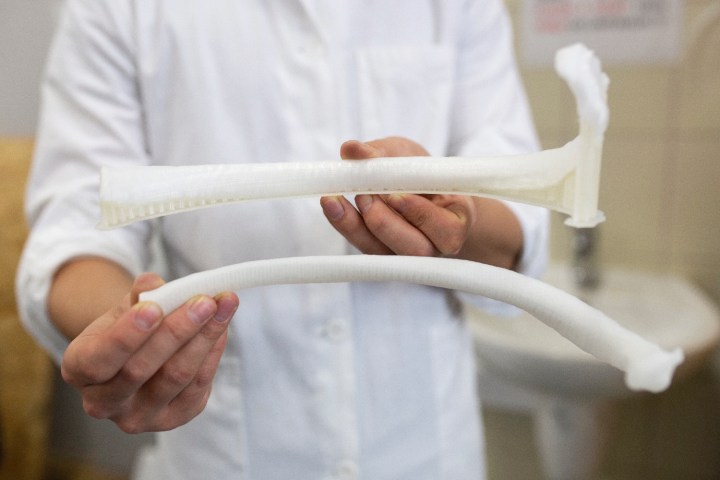

Dr. Tzvetan Minchev, head of the cardiothoracic surgery department at Tokuda Hospital, worked with both 3DGence and 3dBGprint, the latter of which actually created the rib, to come up with a high-tech solution for the problem. The rib was created using an FDA-approved material called Nylon 680, able to both withstand the necessary high temperatures needed for sterilization, and also possessing mechanical properties similar to a real rib.

Sidorowicz says that the patient’s rib cage was scanned and the 3D-printed rib created in less than 24 hours. This was customized to the exact requirements of the patient. It was considerably cheaper than a titanium implant, too — with the cost of the materials, labor, and machine time adding up to less than 100 euros ($114).

This isn’t the only example of 3D-printed bones that we’ve covered at Digital Trends. At the University of Arizona, researchers are investigating ways to mend broken bones using 3D printing and adult stem cells. This research could one day be used to help patients, such as military veterans who suffer combat injuries, which can lead to prolonged ailments and bone defects.

Work carried out at Pennsylvania State University has also resulted in more breathable 3D-printed tissues, which could be used for manufacturing artificial bone and cartilage.

As 2019 progresses, expect to see 3D printing used more frequently in hospitals around the world.