Antilock breaking systems (ABS) have been available on every car sold new for more than a century, it just wasn’t always electronic or automatic. Early on, the driver had to perform ABS duties by repeatedly pumping the brake pedal to prevent the wheels from locking up under heavy braking. It took decades – and a detour via the aviation industry – before engineers figured out how to build sensors that could prevent a lock-up of the wheels under braking.

German engineer Karl Wessel received a patent for an automotive brake force regulator in 1928, but he never managed to bring his design to production. While the need to regulate the hydraulic pressure sent to the wheels under heavy braking was obvious, the lack of suitable technology during the late 1920s prevented engineers like Wessel from developing a commercially-viable anti-block system (ABS) for cars. Keeping it cheap would have made it far too complicated; keeping it simple would have made it way too expensive. Motorists continued to skid out of control like hockey pucks while the technology matured.

ABS began appearing on airplanes and on trains, two types of vehicles that badly needed the ability to stop without skidding, during the 1950s. England-based Dunlop played a pioneering role in developing the technology, and named its mechanical ABS system Maxaret. The feature remained expensive, but it was much easier to offset its cost when building an airplane compared to making a car. Airlines were open to the idea of paying more for a Maxaret-equipped model because the feature could help them save money by reducing tire wear, and even help them make more money by letting planes carry more weight.

British automaker Jensen had its finger on the aviation industry’s pulse.

“As a result of tests, it has been calculated that the allowable operating weight of a particular modern passenger transport fitted with Maxaret could be increased by as much as 15%, a figure representing some eight passengers,” Flight magazine optimistically wrote in 1953.

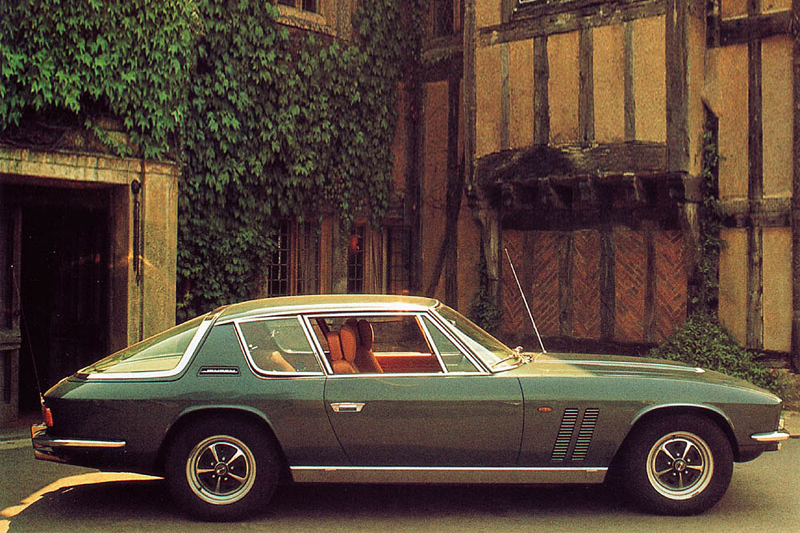

British automaker Jensen had its finger on the aviation industry’s pulse. Its engineers decided to make a sports car equipped with ABS technology after watching heavy planes fitted with Maxaret safely come to a stop on shockingly short runways. The FF that Jensen introduced in 1966 stood out as the first production car made with ABS, and it even came with permanent four-wheel drive, but it wasn’t a mass-produced model that everyone could enjoy. It was an expensive, low-volume coupe sold only in a handful of markets. Jensen made about 320 examples of the FF through 1970.

The FF used a car-specific evolution of Dunlop’s Maxaret technology. While the Jensen model was never officially sold in the United States, American automakers heard about it and forged partnerships with suppliers to make ABS available on their more expensive cars as quickly as possible. Ford developed a system named Sure-Track with Kelsey-Hayes, and released it halfway through 1969 on the Thunderbird as well as on the Lincoln Continental Mark III. AC Electronics helped General Motors develop Track Master, which was available on the Cadillac Eldorado, and True Track, which Oldsmobile offered on the Vista Cruiser (yes, like Eric Forman’s) and the Toronado. Both systems were introduced in 1970.

The three aforementioned systems acted only on the rear wheels because they were more likely to lock up than the front ones. On the surface, this argument made sense: weight moves to the front of the car under heavy braking, so there is less mass over the rear axle. However, the front wheels – which provide most of the braking force – remained at the mercy of physics. They could still lock when the driver mashed the brake pedal to the metal, which made the car unsteerable, especially on wet or icy roads.

The next breakthrough in ABS technology came not from Mercedes-Benz, as many have claimed, but somewhat surprisingly from Chrysler. The Detroit-based automaker teamed up with Bendix to develop a four-wheel, electronic ABS system named Four-Wheel Sure Brake that’s more closely related to the system fitted to every car, truck, and SUV sold new in 2019.

Chrysler claimed Sure Brake relied on “space age computer” technology to keep a car pointed in the right direction under heavy braking.

Chrysler beamed with pride. It called its Sure Brake anti-skid system “the first computer-operated, four-wheel anti-skid braking system offered on an American car.” It didn’t stop there; it claimed Sure Brake relied on “space-age computer” technology to keep a car pointed in the right direction under heavy braking. The feature became available at an extra cost on the 19-foot long Imperial, Chrysler’s flagship model, for the 1971 model year.

Advancements in the field of electronics made Sure Brake considerably more advanced than Maxaret. The system relied on data provided by a small gear linked to each wheel. Sensors measured the gear’s rotation speed by counting its teeth, and converted that information to electronic pulses it sent to a computer that was a little bit smaller than a shoe box. The computer cut hydraulic pressure when it detected a wheel was about to lock (the wheel slowed down before locking), and sent pressure again a split-second later to continue stopping the car. This cycle had the same effect as pumping the brakes, but it occurred up to four times per second, which was faster than a human could manage.

Sure Brake measured the speed of each wheel independently, so the Imperial could come to a safe stop even if two of its wheels were on ice. Chrysler embedded a blue indicator labeled Sure Brake into the instrument cluster to help drivers understand the system. The indicator lit up when the system was active, and it remained on to indicate a problem. The firm stressed the system was fail-safe, so the enormous Imperial would brake normally if Sure Brake shut down for any reason.

Four-Wheel Sure Brake was hugely innovative, and correspondingly expensive. In 1971, the Chrysler Imperial carried a base price of $6,044 (about $38,000 in 2019). Chrysler charged $351.50 (approximately $2,200 in 2019) for Four-Wheel Sure Brake that same year. To add context, an AM/FM stereo with an eight-track cost $419.70, while tinted windows added $58.45, figures that represent $2,500 and $370, respectively. Engineers experienced the system with near-superstitious awe, but Imperial buyers wanted old-school luxury, not cutting-edge tech, and many refused to pay extra for what they considered a useless, over-complicated gizmo. Chrysler dropped the feature in 1973.

Broadly speaking, motorists didn’t accept the merits of ABS technology until the 1980s. Even then, the systems remained expensive, and it took several more years for it to trickle down into the realm of economy cars. It was common to see cars proudly wearing an ABS emblem on the trunk lid in the 1990s, and rightfully so. Chrysler charged LeBaron buyers $954 (approximately $2,000 in 2019) for four-wheel disc brakes with ABS in 1989. Not everyone could afford to tick a $2,000 box on an order sheet.

“This path is leading up into the development of highly automated driving features.”

On the other hand, Mercedes-Benz made the technology standard on all of its cars, from the entry-level 190 to the mighty S-Class, starting in 1984. This decision represented a surprising amount of foresight. European officials made ABS mandatory on all new cars in 2004. The feature has been required – along with electronic stability control – since 2013 on passenger cars and trucks sold in the United States.

In 2019, every car regardless of market segment, price, or body style is developed with ABS in mind from the get-go. Modern-day ABS systems are considerably more sophisticated than Maxaret or Four-Wheel Sure Brake, but they perform the same basic function. Bosch, the company that helped Mercedes develop and launch its first production-bound ABS system in 1978, explained ABS also serves as the foundation for a long list of electronic driving aids that are either common or required on all new cars.

“We’ve added additional functions, like stability control, adaptive cruise control, and hill hold assist, but everything is still somehow based on ABS technology. Automatic emergency braking needs it, too. The technology also supports the regenerative braking function in hybrid vehicles. This path is leading up into the development of highly automated driving features,” Michael Kunz, Bosch North America’s vice president of engineering safety, told Digital Trends.