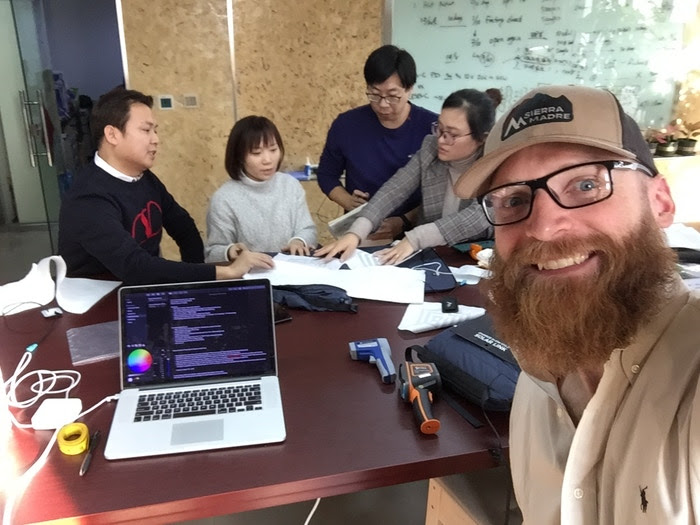

Richard Rhett was hoping his company’s new sleeping bag warmer would be on the market by now. Last spring, his company, Sierra Madre Research, raised more than $625,000 on Kickstarter to make the Hot Pocket a reality.

Rhett then ran into challenges in perfecting the design of the battery-powered compression pack. After making tweaks to get things back on track, he expected to have supplies by March 2020, but the coronavirus, officially known as COVID-19, shut down his Chinese factories about six weeks longer than expected. What’s another month or two for a Kickstarter project that’s already several months behind, right?

Why would he launch himself directly into a wave of oncoming germs?

Well, the Hot Pocket is a warming product and Rhett was hoping to catch the tail end of the cold season in North America. “Honestly, last year’s forecast of what we were going to do this year — that’s all completely changed just because of the product delays,” says Rhett.

The Tennessee-based CEO is just one of numerous startup entrepreneurs impacted by factory shutdowns and business conference cancellations around the world. Some are taking drastic measures to push their suppliers back into production, others are getting creative, and many are just taking deep breaths along with a heavy dose of entrepreneurial zen.

Customers aren’t happy, says Rhett, and cancellations have been higher than usual, between a quarter and a half of a percent. “Anytime you launch an innovative thing that’s never been done before, there’s always a challenge,” Rhett says.

The irreplaceable importance of an in-person nudge

Mikey Wu’s family thinks he’s crazy. The founder of MIKOL, which sells marble phone cases, recently left Taiwan — a country with one of the best-coordinated responses to COVID-19 — to fly into Macau and then drive into China, the epicenter of the disease.

Why would he launch himself directly into a wave of oncoming germs?

“I just want to give people here a push,” says Wu. The people he’s referring to are the workers at the factories that supply the plastic and electronic parts for his luxe phone accessories. After the break from Lunar New Year and the virus, the stock for some of his phone cases is getting low and he’s afraid that if he doesn’t get in front of his suppliers, they’ll focus on jobs from bigger companies. As the CEO of a small company, he feels responsible for making sure parts get approved and shipped out, and everything keeps moving.

“Here, you need to kind of hound them a little bit,” Wu says about his Chinese manufacturers. He’s based out of San Francisco, yet spends over 60 percent of the year in Asia, often visiting the plants that produce his products.

“I found out a week later that the virus was out there.”

Except for trips to the factory, Wu is staying indoors most of the time and being mindful of the local hygiene etiquette, which includes using a tissue to press elevator buttons and wiping one’s feet on an alcohol-soaked welcome mat before walking inside one’s home. On recent plane rides, Wu has occasionally seen some passengers wearing raincoats as DIY safety suits.

Overall though, people have accepted the new normal of social distancing and hygiene in Guangzhou, where he’s staying for the next couple of weeks before relocating to Cambodia, where he can check in on other MIKOL factories. No one is fighting over toilet paper and 2-ounce bottles of Purell. “It’s not as crazy as it is in the States,” assures Wu.

Rethinking the approval chain

Last year, Nathan Staron traveled to China every two to three months to approve new products for the Lithium Battery Company. His most recent trip was in the first week of January, and when he returned he had a fever, chills, and one of the worst respiratory infections of his life.

“I didn’t think anything of it because I didn’t understand what was happening overseas yet,” says Staron. “I found out a week later that the virus was out there.”

During his time in China, Staron did quality control at a factory in Shenzhen, about 700 miles from the major outbreak in Wuhan. This was before Chinese scientists had figured out the genetic sequencing for the new virus on January 12. Staron’s doctor thinks the distance between Wuhan and Shenzhen made him a low risk for contracting COVID-19. Two months later, Staron still feels the effects of the infection in his lungs and, since he was never tested, is worried he may have gotten the virus.

The CEO was supposed to return to China in early February to do more quality control testing. “That wasn’t happening,” he says, “so I had to improvise.” The 165-pound, $5,500 batteries he needed to scrutinize are used by the military in payload transport vehicles — even minor power fluctuations can become major issues. Staron set up a monitoring system he could use to dial into the factory while sitting on his bed in Tampa, Florida. From 11 p.m. to 4 a.m. — Shenzhen’s time zone is 12 hours ahead of Florida’s — he’d log into his supplier’s video-monitoring system and watch workers switch battery packs between testing machines. Then he monitored the testing data from home, checking the numbers for endurance and high temperatures while the batteries were drained.

“Everybody’s super gun shy about putting any money anywhere.”

“Being able to get what I needed to be done remotely through a computer or cameras was a game-changer,” he says. Staron had left a FLIR thermal imaging camera at the plant so workers could share pictures that showed any overheating equipment. He even sent a Wi-Fi controlled robotic camera to roll through the factory so that he could ensure the workers were doing everything properly and he could check the battery serial numbers. Using WeChat, he’d text questions to his co-workers in Shenzhen.

“I’d be telling the engineers: ‘What’s going on with this? Why is this happening?’” recalls Staron. “It was a pretty large production in my home.”

The many ripples of the virus

Julie Weldon’s parents first conceived of a two-in-one, convertible chair 20 years ago, but struggled to bring the concept to market. About 15 years later, she picked up on the concept and in 2019 finally raised $55,000 on Kickstarter to bring the now five-in-one, $349 Wanderr chair to market. The outdoor seating option can also be used to roll heavy loads and do a few other things. The first run of the product was supposed to appear last July, but Weldon and her business partner, Stacey Pierce, encountered the numerous stumbles that can happen when trying to communicate with a factory in a different language and on the other side of the world.

The duo was expecting to receive 400 units of the Wanderr chair before the Lunar New Year. Then that shipment was downsized to 100 units and the holiday and virus-related factory closures happened.

“Even without the coronavirus, 40 to 60 percent of factory workers do not return to the factory after the Lunar New Year,” Weldon says she was told by her supplier in Zhejiang. “It’s an astounding number. And so the factory owner has to find over half of his team all over again, every year.”

Given the current delays, Weldon and Pierce expect that initial run of 400 chairs to be available in July, about a year after they first promised backers they would arrive. A few early supporters have asked for their money back, but most have stayed the course.

“Investing in a game that will release in two years might not be top priority right now.”

“For all small businesses, delays deplete cash without your being able to have inventory to sell and get that cash back in,” says Weldon. “So we still have all the bills without the product to sell.” The cancellation of numerous business conferences also impeded sales for the coming year.

Pierce and Weldon’s company, OME Gear, also happens to be at an important inflection point: Seeking capital at a time when the stock market’s drop has made investors wary. “We’re in a pretty big investment round right now,” says Weldon. “In one respect it’s been great. With the stock market being crazy and bank interest rates being what they are, we’re offering a really great return on their money … but in another respect, it’s a little negative — everybody’s super gun shy about putting any money anywhere.”

An unprecedented experience

Nick Yulman, head of tech and design for Kickstarter, realizes this is a tough time for crowdfunders and entrepreneurs. On March 6, he posted a blog about “How Kickstarter Creators Are Coping with the Coronavirus.” Production delays aren’t limited to China. In the post, Yulman wrote about the Italian startup Relio, which makes modular lighting units for photographers. To keep the assembly line moving, the company ordered four high-quality 3-D printers to bring production in-house and set up a “printing farm.”

“I don’t know that there’s ever been anything that’s exactly like this,” says Yulman, reflecting on the impact of the coronavirus. Still, Kickstarter’s numbers haven’t been impacted by business challenges. In fact, Yulman says fundraising levels for February are up, year-over-year.

Our Trust and Safety team sheds some light on how we're preserving Kickstarter as a space for creative work during the coronavirus outbreak. https://t.co/f7gD9W5uK3

— Kickstarter (@Kickstarter) March 26, 2020

He and his team are doing what they can to work with some of the entrepreneurs utilizing Kickstarter — ensuring that the production estimates they get from factories are realistic and the messaging to backers reflects any potential production delays.

“It’s not much comfort, but one upside of this being such a widespread story, and it affecting so many people, is that it’s not really news to folks,” says Yulman.

For the past four months, Philip Barclay’s team at Sabotage Studio has been planning to launch its new video game with a Kickstarter campaign and a series of meetings at San Francisco’s Game Developer’s Conference, which has been turned into a virtual event. Now the Quebec-based company has canceled its in-person presence and made many meetings videoconferences. Then last week, Sabotage sent everyone home, following the social-distancing protocol requested by the Canadian government.

Now the team has to launch and coordinate a campaign from home, in a battered economy. Given that more people, including gamers, are spending time in front of their screens, getting attention may be easier, but many people are also fearing a financial pinch.

“Getting financial support might prove to be much harder; considering investing in a game that will release in two years might not be top priority right now,” acknowledges Barclay via email. “There is also a major risk of mediatic eclipse, if big news related to the coronavirus outshines all our marketing efforts. We had another sanity check this morning, and confirmed that we’re sticking to the plan to go ahead … It is extremely stressful to feel like the success or failure of the campaign relies mostly on external factors.”