When it comes to humans visiting Mars and needing somewhere to stay, NASA has an ambitious plan: To use raw materials found on the planet to 3D-print a habitat in situ. That was the subject of the 3D-Printed Habitat Challenge that the agency kicked off a few years ago, which invited teams of designers to pitch their best solution to the problem.

So how exactly do we transform a bunch of Mars dust into a comfy home? To find out, we spoke to two experts who participated in that competition — architect Trey Lane from the winning Team Zopherus and engineer Matthew Troemner from the Northwestern University team — about how to design and build a habitat on another planet.

This article is part of Life on Mars, a 10-part series that explores the cutting-edge science and technology that will allow humans to occupy Mars.

Using local resources

When planning a habitat for Mars, the biggest limitation is how much material you can bring from Earth. Every extra gram of mass loaded onto a rocket has a significant cost in terms of fuel, so it’s just not feasible to bring along a building’s worth of construction materials. That’s why the first habitats will need to be built using raw materials that are available locally on Mars.

It’s certainly a different way to approach construction, as Trey Lane, architect from the competition-winning Team Zopherus, told us.

“From an architect’s point of view, there’s a certain amount of freedom that’s opened up when you’re 3D printing.”

In his early research, Lane didn’t find much in the way of large-scale 3D printing projects using local materials, so he turned to an unexpected source for inspiration: Insects. “We started looking at wasps and spiders and beetles,” he said. “For hundreds of millions of years, they’ve been doing essentially 3D printing to create habitats.” Insects go out into the environment, find resources, process them into usable material, and construct the most practical habitat to meet their needs — just like what Lane wanted to do. “We found, honestly, that insects are better models for how to construct a 3D-printed, autonomous, local resource utilization habitat than humans are.”

His team envisioned a habitat that included rovers that would go out into the environment and collect materials, then bring them back for further construction. “In a lot of ways, it’s like a wasp that goes and chews up a little bit of local resources and turns that into a papier-mache and builds its nest out of that.”

There are advantages to applying this approach to construction, whether on Mars or on Earth. “The fact that you’re using local resources makes a huge difference for space missions,” he said. Instead of relying on long supply chains, you can be much more efficient in terms of materials and energy. Plus, the 3D printing approach is safer than traditional construction. “Construction is a risk-prone industry … So if you can do certain aspects of that autonomously, you have a safety benefit as well.”

It can also be faster and cheaper to 3D-print, and there’s a degree of design freedom it enables. “From an architect’s point of view, there’s a certain amount of freedom that’s opened up when you’re 3D printing,” he said. You don’t have to rely on mass-produced materials like two-by-fours, which tend to be flat and straight, so you can design more complex shapes. “It frees you up to create a design that is custom-fit for the solution.”

How to 3D-print a habitat

When you think of 3D printing, you likely think of a desktop machine for printing items a few inches wide. When it comes to infrastructure-scale 3D printing, you need much larger hardware, but it’s a conceptually similar process — “in that you’d use similar software, you’d use similar movement techniques,” as Matthew Troemner, Ph.D. candidate at Northwestern University and leader of the university’s Mars habitat team, explained.

The difference is in the way material is deposited. Desktop 3D printers use a fused deposition method, “which is like a melted plastic string, essentially,” Troemner said. And while it is possible to scale this up, for printing on Mars, Troemner’s team wanted to use a different type of material called marscrete, or Mars concrete. “We’re pre-mixing material, creating a kind of paste, and then extruding it” before allowing it to cure or harden, he explained.

Marscrete is made by mixing Martian regolith — the dusty soil-like substance that covers the planet’s surface — with sulfur. Sulfur concrete has been used on Earth for decades and is strong and resistant to wear, which makes it ideal for building on Mars. Once it’s mixed, it can be laid down into shapes to form a habitat.

“For Mars or space applications, you’d have some kind of arm that moves and deposits material,” he said. On Earth, arm-style mechanisms are less popular than gantry-style mechanisms for large-scale printing because they can only print at a limited size — essentially, the reach of the arm. But the more complex the printing hardware, the more things that can go wrong. There’s a value in keeping things as simple as possible when building on another planet.

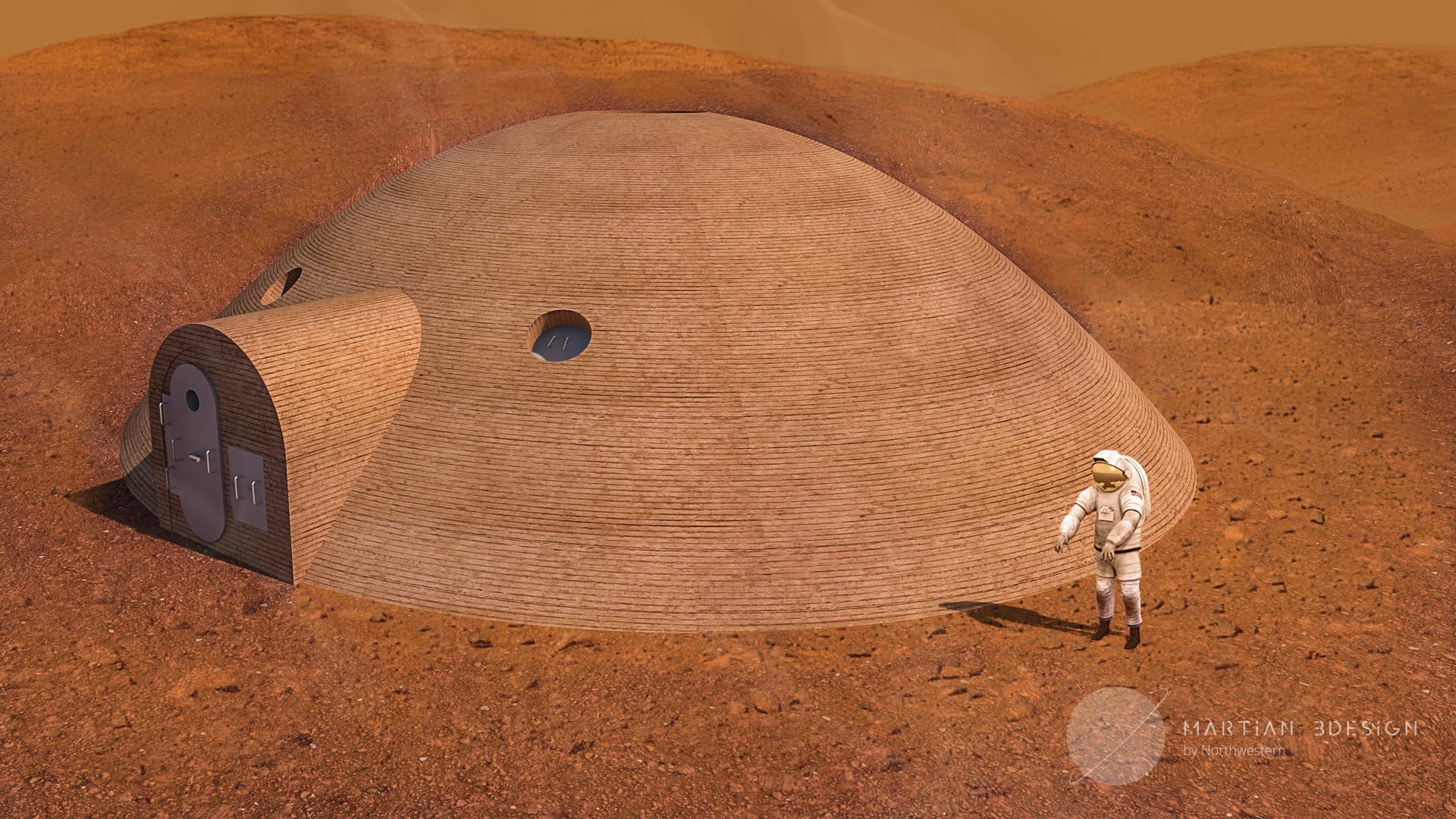

Troemner’s team proposed using an inflatable pressure vessel — essentially, a giant, strong balloon — which would be filled with air to form a dome shape, with an arm mechanism used to print marscrete on top of that. The pressure vessel keeps air in and radiation out, and the marscrete makes the structure strong and durable.

The challenges of building on Mars

Mars is inhospitable to both humans and buildings. For a start, there are the temperature swings on the planet, with temperatures around the equator ranging from a high of 70 degrees Fahrenheit (21 degrees Celsius) during the day to minus 100 degrees Fahrenheit (minus 73 Celsius) at night. That puts a lot of stress on building materials.

“We wanted to have structures that could expand and contract independently of one another,” Troemner said, to allow for expansion and contraction over Mars’s very cold nights and relatively warm days. And the structures need to be strong enough to withstand the buildup of dust from the planet’s frequent dust storms. “If you do have a pile of sand on half your structure, you have an unbalanced loading condition, what is that going to do?” he explained. Dust storms can also affect construction, meaning there is a need to allow for downtime.

That’s why Troemner’s team came up with the idea of domes. “Domes are a good shape for the thermal expansion and also the sand dune buildup,” he said, and they distribute loads very well. Builders are actually given a little help by the reduced gravity on Mars as well, “so you need fewer structural elements, you need a lighter piece of equipment.”

One big issue is how to protect Martian astronauts from dangerous radiation. “Martian regolith isn’t really that excellent at shielding from the radiation you’d experience on the surface,” Matthew said. The dome design would have between one and three feet of material between people inside the habitat and the exterior environment, but that wouldn’t be enough to protect astronauts inside.

Adding sulfur to the regolith to make marscrete helps, but the team also added polyethylene fibers to the mix, which would add to the shielding effect. For complete shielding, the interior inflated structure would have more polyethylene too. This polyethylene could be cannibalized from the lining of the uncrewed spacecraft that would carry the first wave of supplies to Mars.

The role of architecture

Designing a habitat isn’t only about engineering challenges though. It’s also about creating a space in which people can live and work comfortably for a long period of time, potentially while under a lot of stress or experiencing profound isolation.

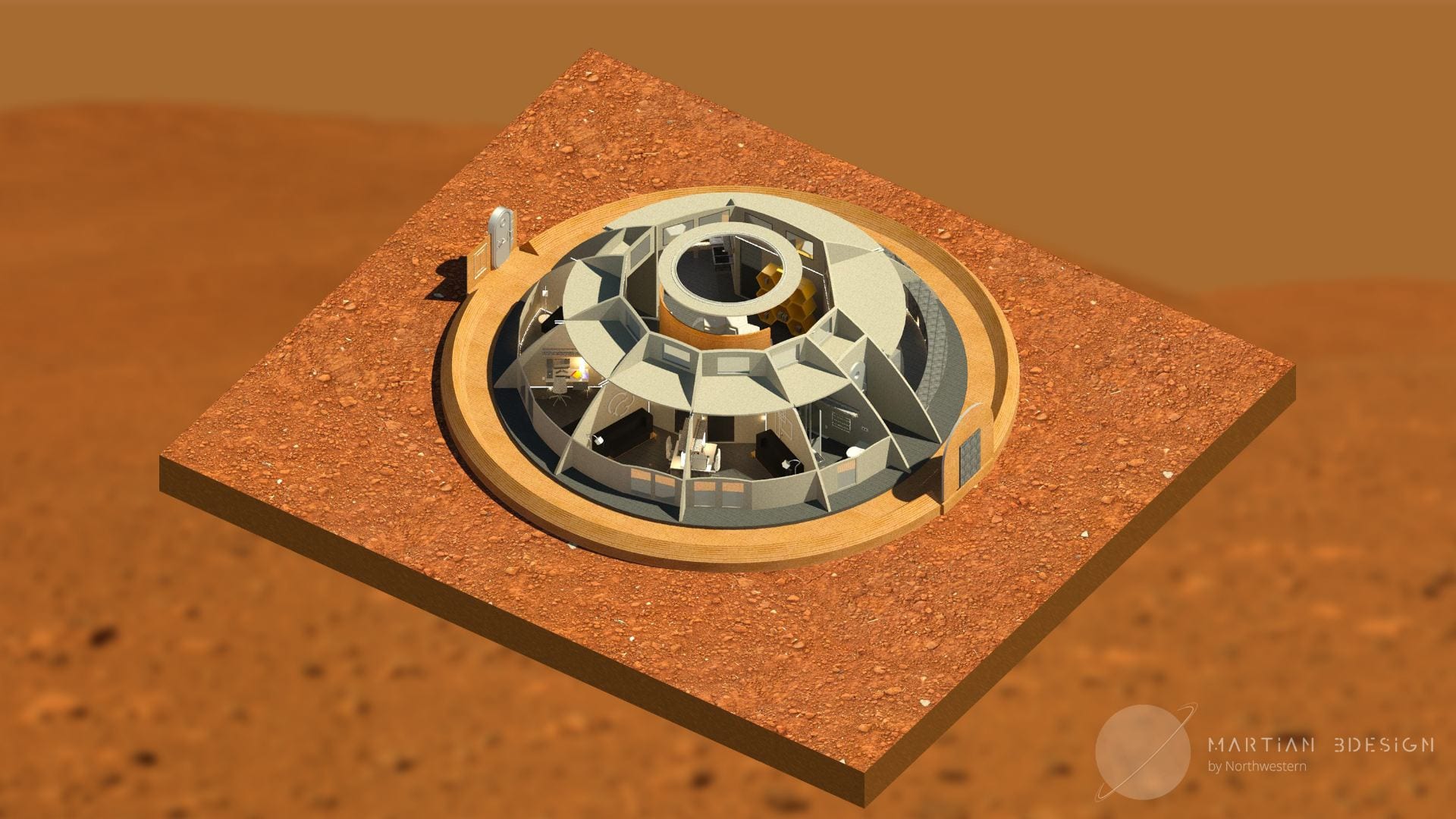

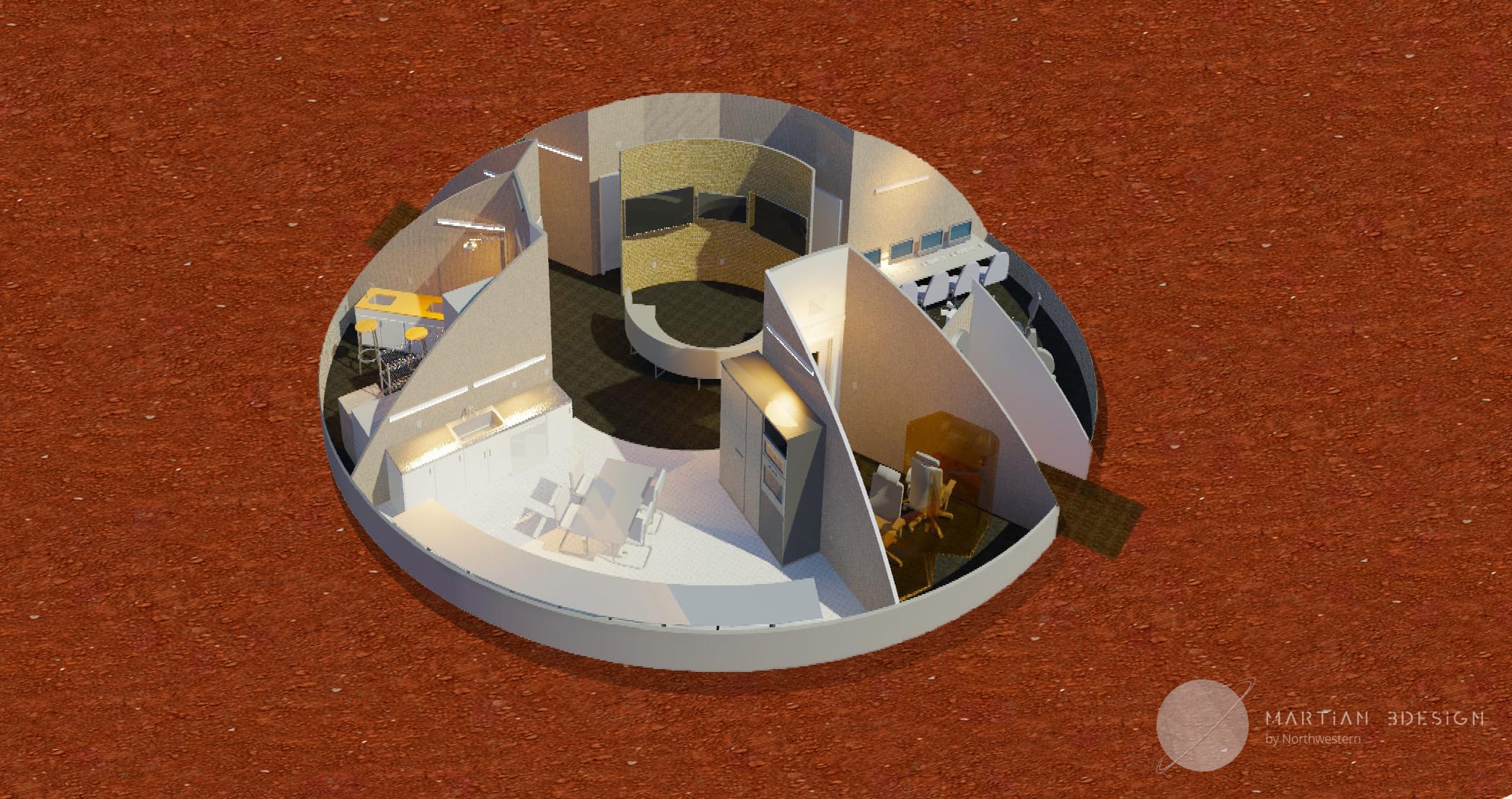

Team Zopherus’ habitat was divided into three modules: A laboratory for science operations, a communal unit, and a crew unit for needs like sanitation and sleeping quarters, with the possibility that more units could be added based on mission needs.

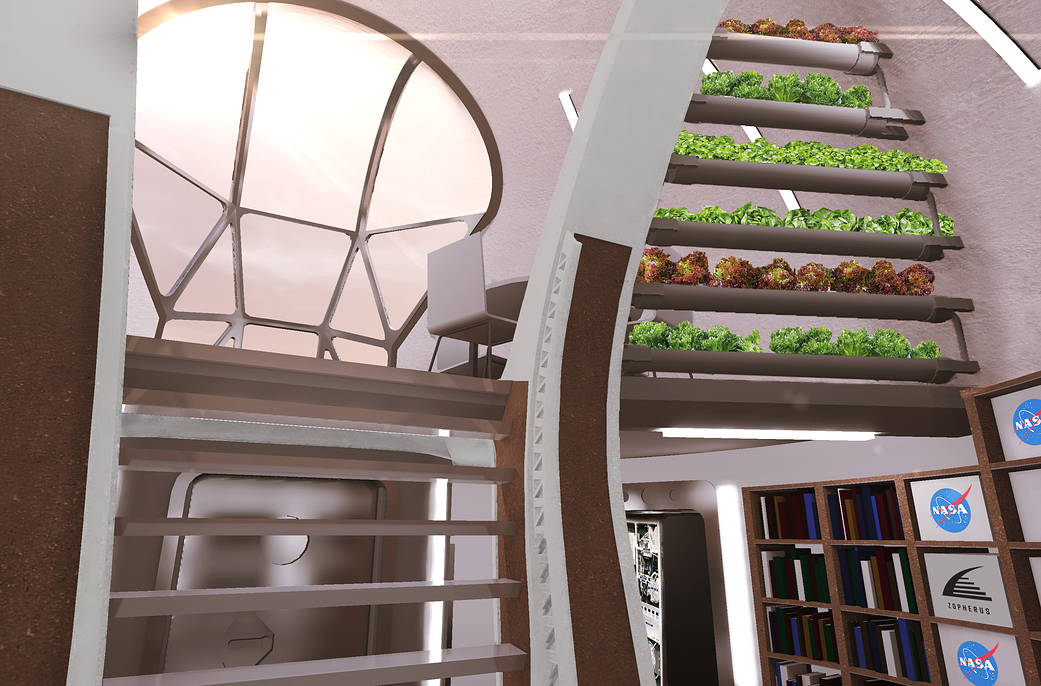

They wanted the space to support both the practical needs and the psychological needs of astronauts staying there, which was reflected in how they designed the communal unit. “We really oriented that space around a large opening on the upper level,” he said. A large window allows astronauts to look out onto the surface of Mars while staying safe and comfortable inside. “We wanted to maximize the astronauts’ ability to see their surroundings and connect with it.”

That’s important for completing tasks like, for example, using a mechanical arm to move things around outside. But there’s a significant psychological benefit as well. “If you’re cooped up in about a thousand square feet of space for a year on a planet that wants to kill you everywhere except for right where you live, feeling like you’re not in a can is really beneficial,” he said.

Designing to benefit astronauts psychologically isn’t about making a building attractive for the sake of it, but about finding the best solution to a design problem.

The team also added the hydroponic garden to this space both so that plants can get light and so that astronauts walking below would enjoy the psychological break of feeling like they were walking through a wooded space. For Lane, balancing this intersection of practical and psychological needs is a key job of an architect. “Architects interface between the needs of humans and the physical environment,” he said. “The physical environment that someone is in affects them psychologically and also operationally.”

The way he thought about it was not in terms of separate mission needs and psychological needs. Instead, he sees those as interlinked. “Those psychological needs are actually practical needs when you’re dealing with a human,” he said. “Because the psychology of your astronauts directly affects their performance on the mission.”

Designing to benefit astronauts psychologically isn’t about making a building attractive for the sake of it, but about finding the best solution to a design problem. He pointed out the elegance and beauty in many aspects of space engineering. “There’s really something beautiful about design that fits the problem well,” he said, similar to the inherent beauty in many organic shapes. “Following the pragmatic constraints of the design problem, and taking into consideration occupant health and wellness and psychology results in something that is probably going to be more aesthetically pleasing design.”

“You can go too far in making something pretty,” he said. “But making it work well for the person who’s going to be inhabiting it, for me, is a very practical consideration.”

Going underground

Both experts agreed that the future of Mars habitat design had many possibilities, including potentially moving below the surface. Constructing an underground base has many advantages, like keeping people safe from radiation and dust storms. But it has its challenges too.

When it comes to underground construction, “There’s still so many unknowns,” Troemner said. There’s much we don’t know about the composition of the Mars subsurface and how to construct in that environment. “At least for a first step, if we’re talking about the near future, something on the surface makes more sense because there aren’t those same levels of unknowns as there would be when digging down.”

Once we’ve been on Mars for a while though, that might change. “Long term, after you’ve created a first few initial structures, you’ve had more rovers on the surface, maybe you’ve had astronauts on the surface, then maybe an underground base is the way to go in the future,” he said.

Lane agreed. He thought the first mission to Mars might involve people staying in “stuff on the surface which mostly came from Earth,” like the Apollo missions to the moon. But for more people staying for longer periods of time, you need more permanent infrastructure. “At that point, you start going underground or 3D-printing your habitats,” he said.

Eventually, Lane envisioned a wide variety of habitats designed and built by different space agencies or companies. “We’re going to see more variety in our habitats that we’re creating, because our needs are going to be more varied, and we’re going to need to accommodate more scale,” he said. From that variety, we’ll learn more about what the best way to live on another planet is, which will help us build even better habitats in the future. “Which is something that I’m really excited about, in the next decades of humans venturing out onto the moon and Mars.”

This article is part of Life on Mars, a 10-part series that explores the cutting-edge science and technology that will allow humans to occupy Mars.