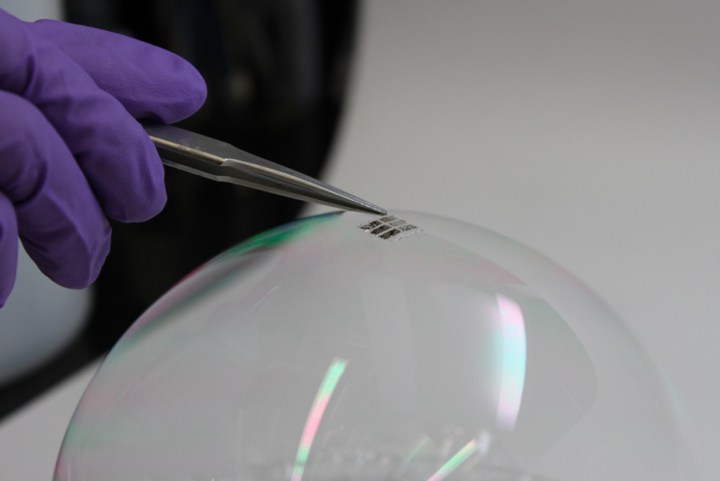

The team at MIT, made up of Vladimir Bulovic, the associate dean for innovation, research scientist Annie Wang, and doctoral student Joel Jean, made the cell in a completely new way, where three steps are combined into one, and the entire process performed in a vacuum. The finished cell is only two micrometers thick. That’s an astonishing one-fiftieth the thickness of a hair on your head.

Surely something so tiny and light can’t produce much power. That’s certainly not true here. According to the team, a regular silicon-based solar module will kick out 15-watts of power per kilogram. The solar cells, which have been made using flexible parylene, have a much improved power-to-weight ration of 6-watts per gram, which is about 400 times greater. That’s impressive for something that’s described as being, “so light you don’t even know it’s there,” by the development team.

Imagine the potential of tiny solar cells capable of providing power to almost anything, without adding huge amounts of weight. From a wearable device on your wrist to a smartphone in your pocket, to giant vehicles and beyond. Spacecraft and balloons that are used for research at high altitude are also mentioned as possible use cases. The cells could even be added to paper without affecting its weight. However, it’s also stated that the cell as we see it here probably doesn’t have many practical applications, because simply breathing in its direction would see it fly away.

The new solar cells have already taken years to develop, and should still be considered a proof-of-concept, therefore not ready for integration with hardware just yet. Bulovic said the next stage of creating a product that’s suitable for mass manufacture, “will take time,” and a, “lot of hard work,” but added that, “likely no miracles” will be needed to reach that stage.