“The wife of one of my friends runs a 3D printing company, printing cookie-cutters for Etsy,” Mark Silliman, one of the co-founders of Oregon-based startup Tend.ai, tells Digital Trends. “I used to watch her run to the garage, where she kept her printers, every five minutes throughout the day — just in order to keep up with demand. I thought that there had to be a better way.”

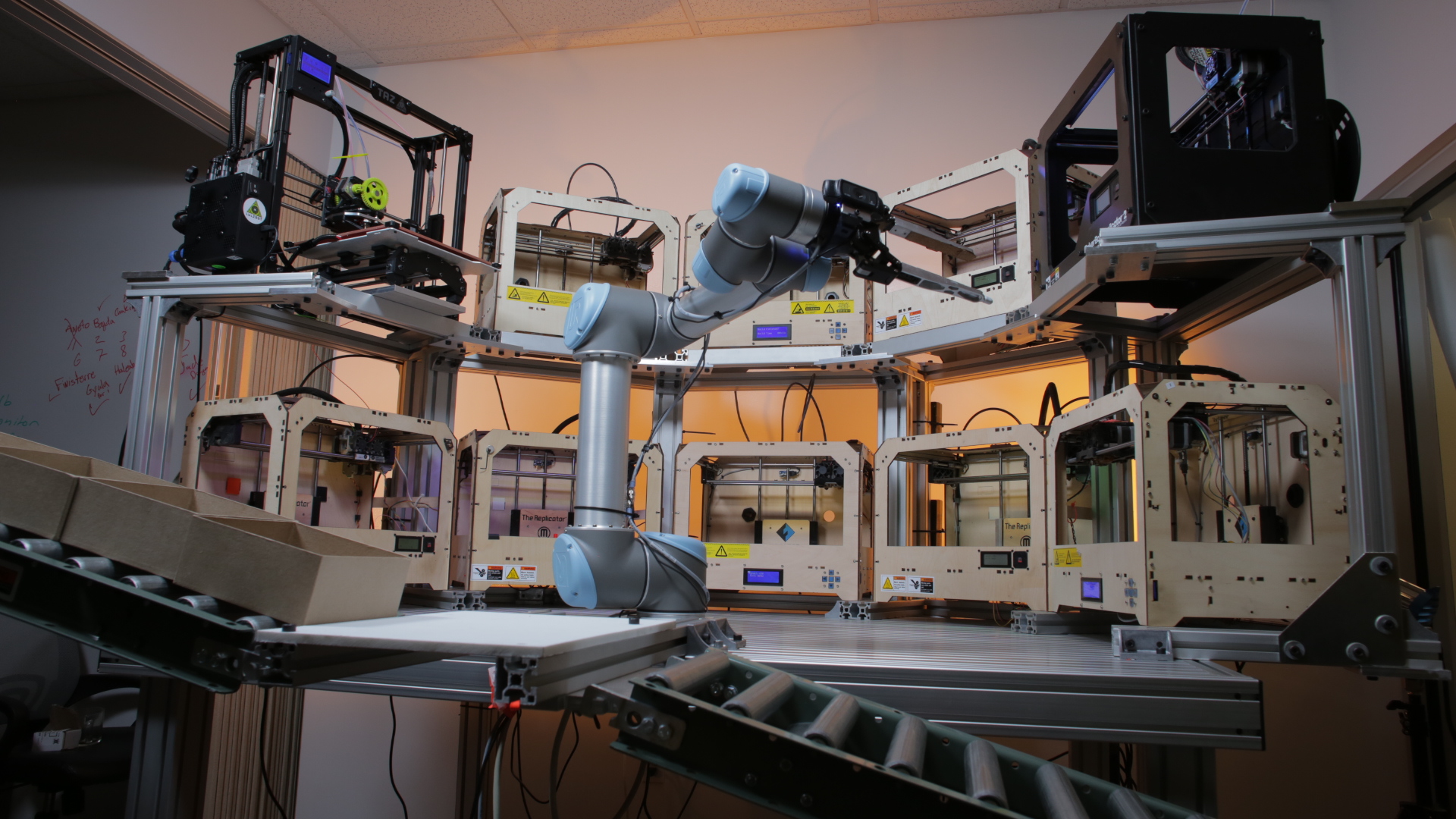

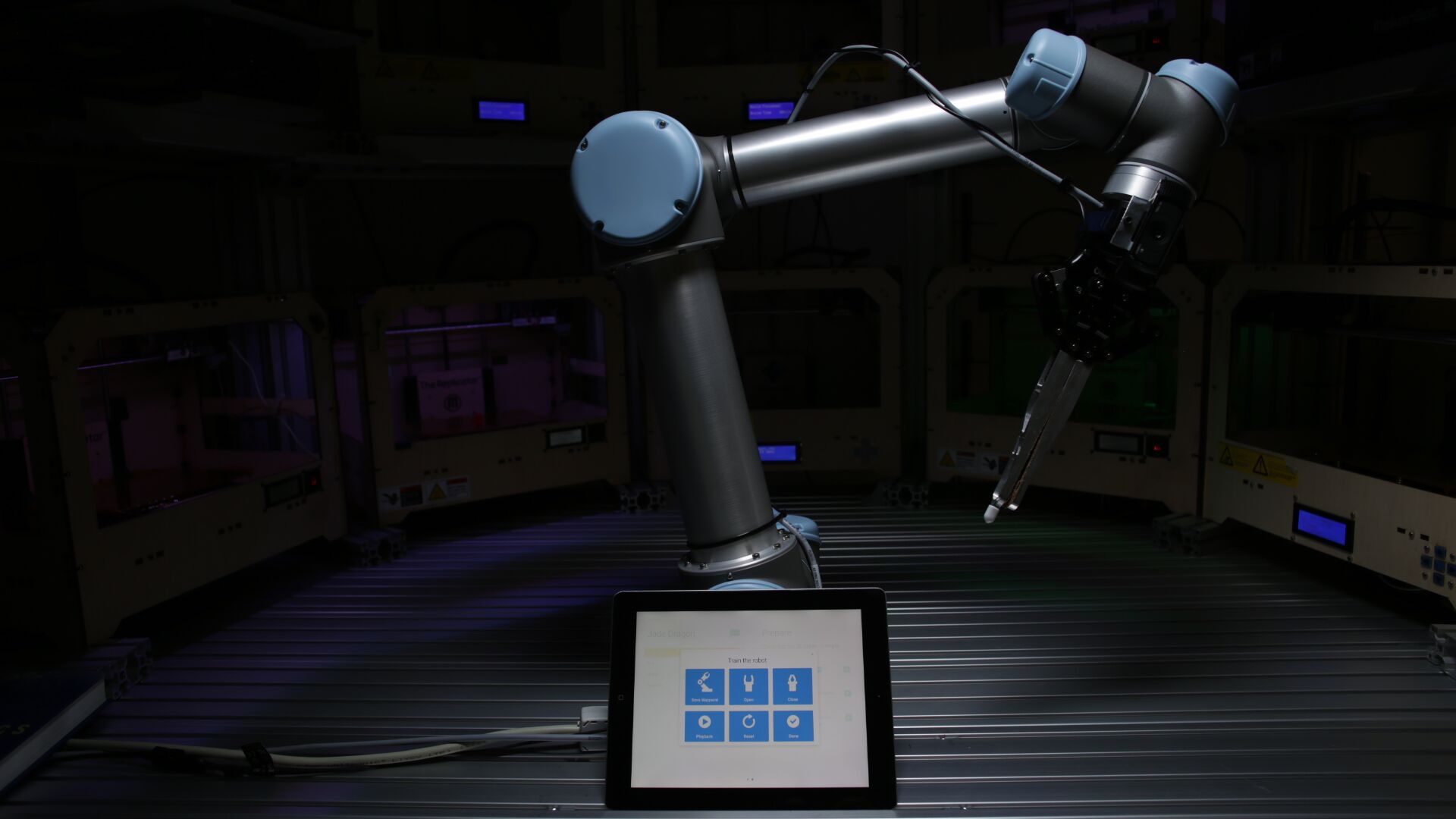

Like any entrepreneur worth his salt, Silliman thought that “better way” could have the makings of a company. Together with two collaborators, Robert Kieffer and James Gentes, they created a cloud robotics company (“Your hardware, our software”), able to train collaborative robots to carry out complex multitasking — such as operating an entire 3D printer farm without the need for much in the way of human intervention.

“This is something that wasn’t even viable 18 months ago,” Silliman says. “These robots have only just arrived on the market. We hope that Tend.ai will have a place in this community, and not just in terms of 3D printers. Laser-cutters are another application this idea could easily be applied to, and there are far more. One of the most exciting things about modern robots is that they can adapt to a wide variety of tasks. It’s just a matter of the right software. A small business can rationalize buying a robotic arm if they know that it can adapt as their needs change. That’s where we come in.”

Based on the above video — in which a single robot arm handily operates 10 separate 3D printers, using a basic webcam to read each printer’s display, while also removing the final 3D-printed products from the printbeds for boxing — Tend.ai is just getting started! Who couldn’t love that kind of innovation?