Daimler has been 3D printing plastic spare parts for older commercial trucks for about a year, and now it’s moving on to metal parts. The company recently 3D printed its first metal replacement part, a thermostat cover for older Mercedes trucks and Unimog utility vehicles. Daimler believes 3D printing could be a cost-effective way to keep spare parts available indefinitely.

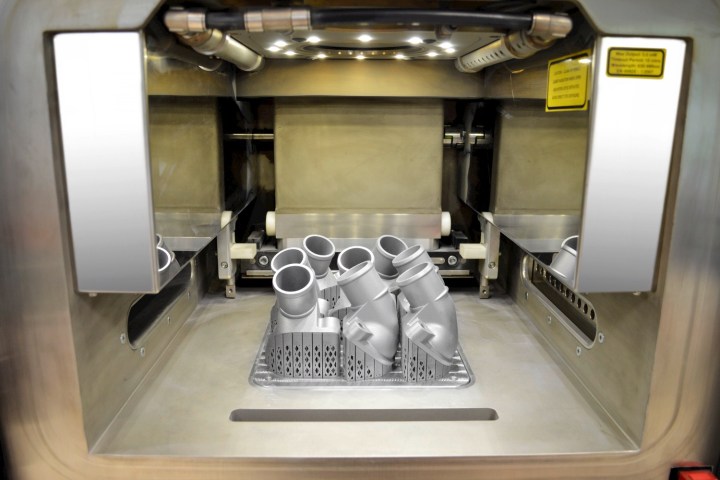

Like other 3D-printed objects, the thermostat covers are made by adding material in layers until the proper shape is achieved. In this case, the material is an aluminum-silicon powder, which is melted using lasers.

Daimler claims the 3D-printed parts are just as strong as the die-cast aluminum versions installed on the trucks when they were new. The company also claims 3D printing is more cost effective than tooling up for a production run using conventional methods. That makes it perfect for producing spare parts, which are usually only ordered in small batches. It also means Daimler can make parts on demand, instead of warehousing large stockpiles.

The trucks that use the 3D-printed thermostat cover went out of production 15 years ago, and the part isn’t used on more recent models. Consequently, there is no reason for Daimler to keep the part in production. But customers who want to keep their older trucks running may need it, and Daimler’s ability to quickly whip one up using 3D printing saves them from having to scrounge for a used one.

Daimler isn’t the first manufacturer to experiment with 3D printing. Ford has used 3D-printed parts on race cars, and it’s investigating the use of 3D printing to help customers personalize their cars. But so far, automotive 3D printing has been limited to small-scale applications.

Local Motors famously 3D printed the entire body of its Strati electric car at trade shows, but more traditional automakers probably won’t embrace this approach anytime soon. Current manufacturing methods have a proven track record, and there is too much at stake for automakers for them to switch to something completely new so quickly.