Ford is continuously seeking ways to apply the technology it’s developing for cars to areas outside of the automotive industry. Its latest project was creating a self-driving, multi-purpose robot. It’s not as anthropomorphous as Asimo, Honda’s eerily human-like (and recently retired) robot, but it’s capable and smart enough to give assembly-line workers a hand. The robot works daily in the company’s Valencia, Spain, factory.

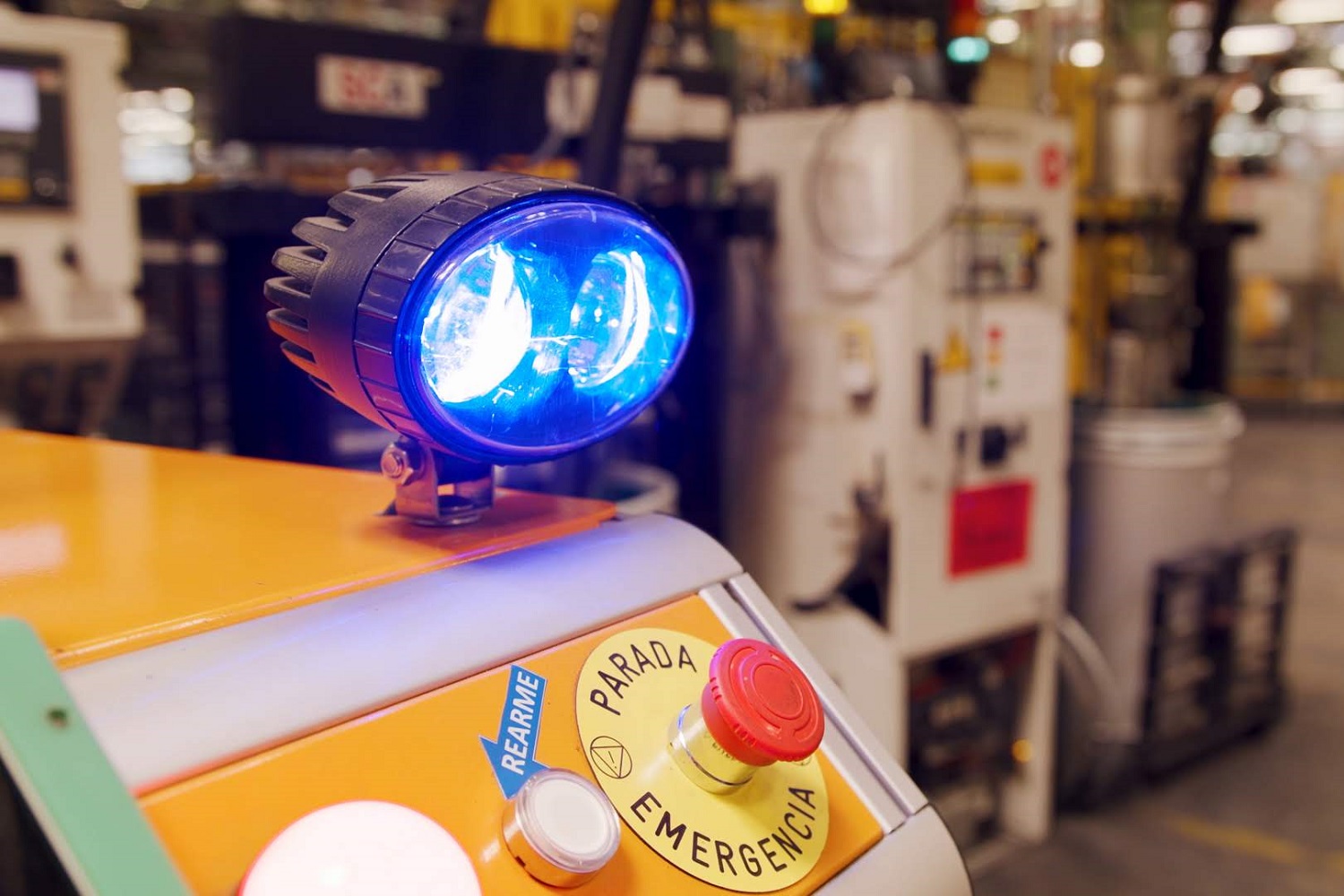

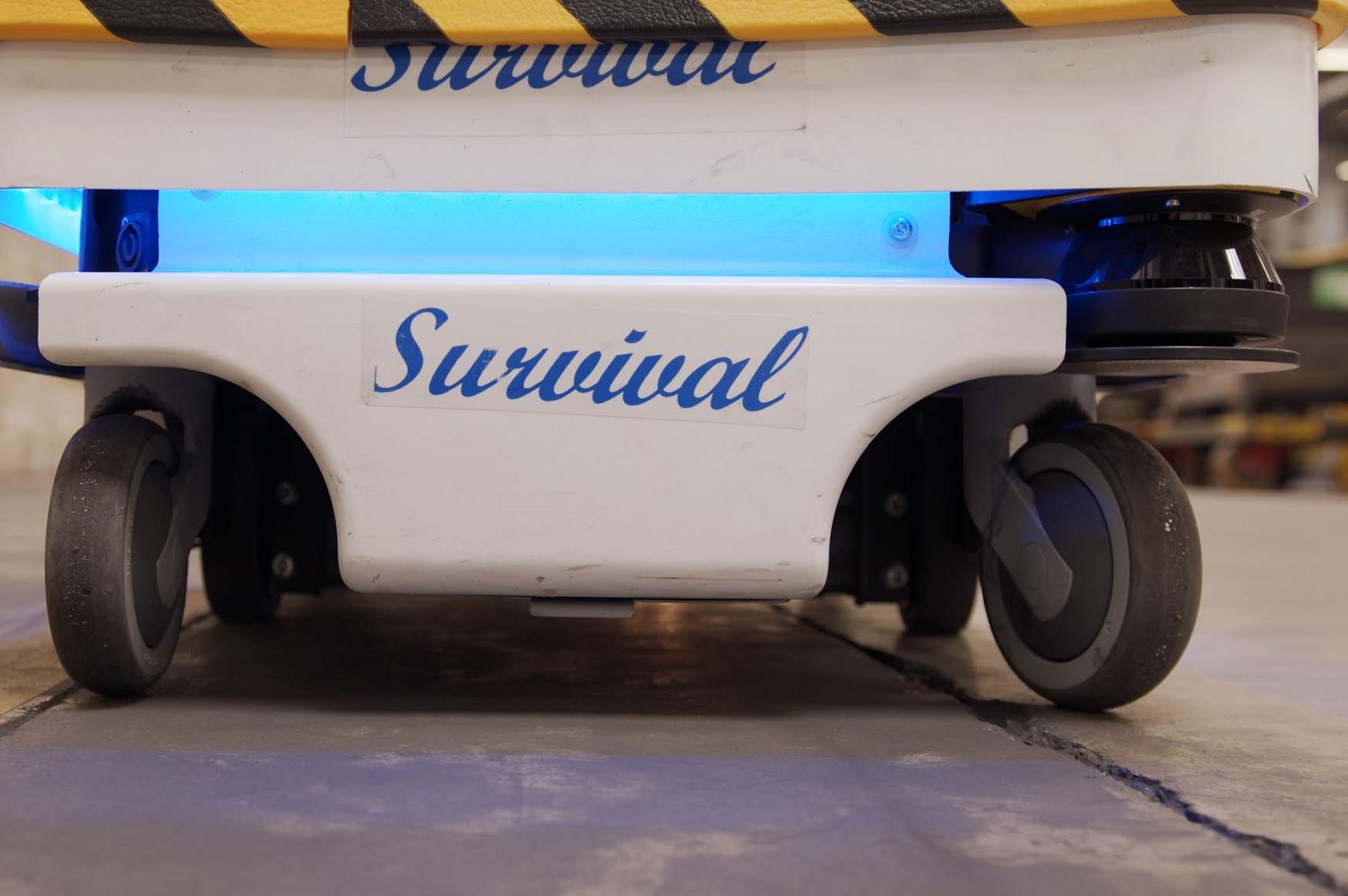

The robot’s uncanny ability to adapt to its environment earned it the nickname Survival. Developed in-house by Ford engineers, it looks like an Ikea filing cabinet on wheels that slowly zig-zags across the factory as it delivers parts and welding material to the various stations that build cars. It avoids obstacles when needed, either by maneuvering around an object in its way, or by stopping until the coast is clear, and it can find an alternate route to its destination if needed.

Survival looks like it was beamed to Ford’s Valencia factory from a science-fiction movie. But while it sounds like it’s powered by ultra-advanced artificial intelligence, Ford explained it relies on relatively simple technology to move around on its own. An array of sensors borrowed from Ford’s autonomous car development program tell it when something is in its way, and it memorized the layout of the factory.

“We programmed it to learn the whole of the plant floor so, together with sensors, it doesn’t need any external guides to navigate,” engineering manager Eduardo García Magraner said in a statement.

Working alongside a robot takes some getting used to. García Magraner said the robot caused a big stir when it first started meandering across the factory. Workers went out of their way to give it space, walk around it, and stare at it as it nonchalantly rolled by. The awkwardness didn’t last long; everyone is used to working alongside the robot now, almost a year after it first went live, and assembly-line workers have accepted it as part of their team.

It’s a big help, too. Ford developed it to perform tasks that are time-consuming, boring, or both. It has 17 slots that allow it to carry material and parts of different weight and sizes. The idea isn’t to replace humans, the company stressed, but to relieve them of mundane tasks. Survival saves 40 work hours daily, which lets assembly-line workers focus on more complex tasks.

As of this writing, Survival is a one-off, a lone automaton in a swarm of humans. But as the end of its testing period nears, Ford is beginning to look into putting it into full-time use in Valencia, and it’s considering building additional examples to deploy them in other European factories.