The RC F, packed with a 5.0-liter V8, sends 467 horsepower and 389 pound-feet of torque to the rear wheels. When it gets there, the torque vectoring differential divides the torque between the two, providing stability on the rear axle in situations where the driver might lose it.

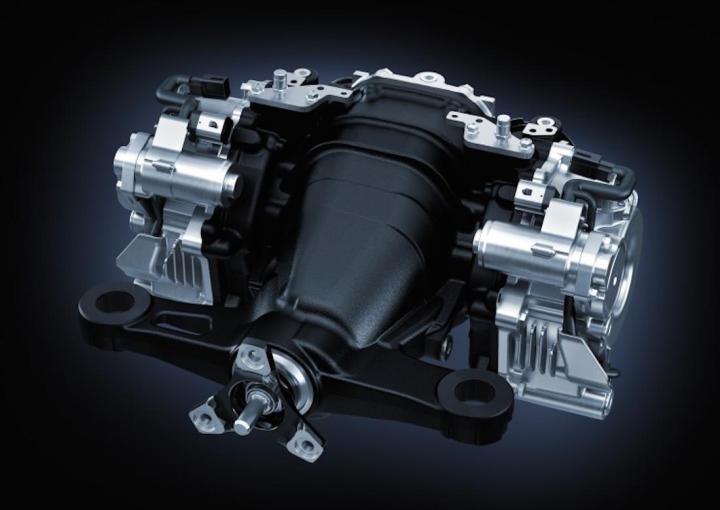

How this differs from a standard differential is that, where as a basic mechanical diff spins the outer wheel faster than the inner wheel (it has longer to travel), the TVD in the RC F employs electronic motors and actuators that apply pressure to multi-plate clutches that can control the distribution of torque.

Essentially, while good ol’ physics will get the differential to split the torque between the wheels, the electronics can now influence things when it sees fit, “vectoring” the torque where it senses the car needs it the most.

In a track application, putting a ton of torque on the inside wheel of a turn would basically put the brakes on it, having the outside of the car sort of pivot around it, making tight corners easier to handle. Specifically for the RC F, there’s three modes that can be manually selected: Standard, Slalom, and Track. Standard (surprise) is the basic driving configuration, while slalom optimizes the response for quick left-right alternating experienced on twisty back roads. Track mode puts an emphasis on keeping the rear axle stable at high speeds.

Related: Hot Fuzz: Dubai’s Police force deputizes the Lexus RC F

That’s (hopefully) the easy to digest version. Lexus also provided a link to a video posted by Engineering Explained, which features the RC F’s TVD for a more in-depth explanation of how a torque vectoring diff works.