This flaw is fundamental to how NAND is designed. Data is held using an electron charge which is used to determine whether a particular section of memory holds a 0 or 1. As it’s used, though, the insulation layer that traps the electron can wear out. That eventually makes accurately determining the value of a particular memory cell impossible.

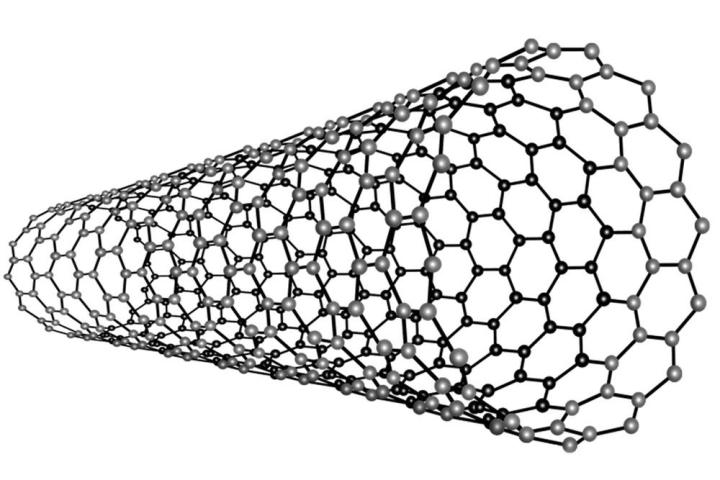

NRAM works differently. Its built from layers of carbon nanotubes. Where the nanotubes are close, electrical resistance is low, and high where they’re further apart. Voltage can cause the nanotubes to switch between these states, which lets NRAM store a 0 or 1.

Nanotubes are extremely durable, and as a result they can handle a practically infinite number of read-write cycles. As an added bonus they can tolerate heat, cold, magnets and radiation that would kill NAND memory (or other types of storage, for that matter). They’re allegedly quick, too, allowing configurations that can saturate a DDR4 channel.

This technology, if it comes to market, may not have an immediate, obvious impact on consumer solid state drives. Its durability will be appreciated by data centers, though, as well as anyone building supercomputers. The company behind is, Nantero, says it is currently working with “two of the top five semiconductor foundries,” according to The Tech Report.

A release date for the first products with NRAM has not been announced, but the company behind it says the first incarnation will be fabricated on a 20-something nanometer process, which likely means it’s nearing production.