Technology is incredible, but oftentimes it’s not exactly environmentally friendly — at least not when it comes to disposable electronics. That’s why researchers and scientists all over the globe try to figure out ways to limit electronic waste, and this time around, they may have found an unexpected solution in … paper.

According to a recent study, making printed circuit boards (PCBs) out of paper could be the future of eco-friendly electronics. Here’s what we know about it.

Right now, PCBs are made from materials that are not eco-friendly at all, including resins, metal wiring, and glass fibers. Found in so many different kinds of electronics, these circuit boards — along with the devices they’re critical parts of — often end up in landfills, adding to the already immense amount of waste our planet has to deal with. Solutions are needed, and sometimes they’re more creative than one might expect.

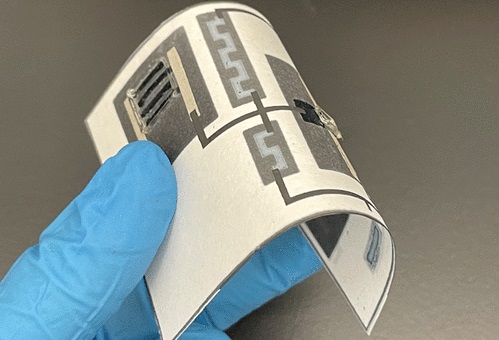

A research team from the State University of New York at Binghamton took a deep dive into the topic of creating paper-based PCBs, and according to the study, they were successful. Dubbed “Integrated Papertronic Techniques,” the study explores embedding resistors, supercapacitors, and transistors onto a thin and flexible sheet of paper. At the end of the product’s life, such a PCB could be recycled or simply destroyed without harming the environment.

The study comes with a quick diagram that shows how such a PCB could be made, and it looks simple enough despite being cutting-edge technology. The wax pattern is printed at first and then melted at 130 degrees Celsius in order to make it soak into the paper. Next, conductive ink is injected into the pattern, additional metal components are screen printed, through holes are cut out with a laser, and a gel-based electrolyte is added onto the sheet of paper.

The inks are capable of forming transistors, resistors, and capacitors, and the whole structure is supposedly just as flexible as the paper it was added to. It’s thin, too, and completely degradable — it lit on fire and turned to ashes as part of the testing. Alternatively, it can be dissolved in water and recycled to some extent.

Unfortunately, paper-based electronics have one glaring downside — they’re unlikely to do well when faced with humidity. On the other hand, most of us tend to avoid submerging our expensive electronics in water, so for some use cases, this can definitely work.

We’ve already seen honey-based chips, and now we’re seeing paper-based PCBs. What’s next? Hard to say, but it’s always great to see an innovative approach to ongoing problems.