At the beginning of 2015, Ray Flynn couldn’t see a thing in front of him. The 80-year-old suffered from a common disease called dry age-related macular degeneration (AMD), which caused him to lose his central line of sight and required him to rely on his peripheral vision instead. Flynn couldn’t use ATMs and had trouble distinguishing weeds from flowers in his garden. But in June, Flynn received the world’s first retinal implant to treat AMD, a procedure that left the patient with a bonafide bionic eye.

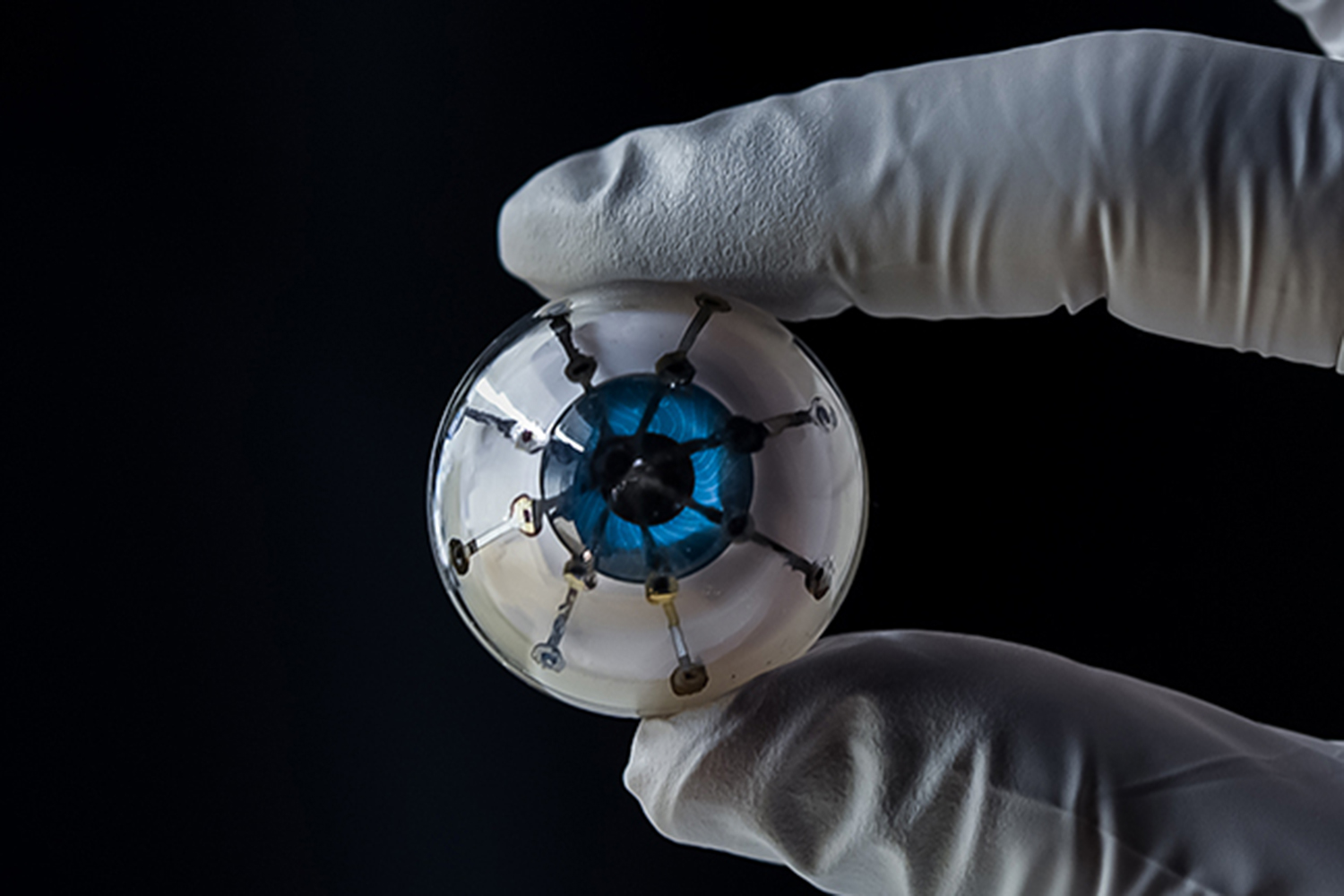

Now, engineers from the University of Minnesota have made another significant step in the development of bionic eyes. In a paper published this week in the journal Advanced Materials, the researchers describe how they 3D printed a prototype for a synthetic eyeball, equipped with photodetectors that allow the device to pick up light. The prototype could help usher in more advanced devices for visually impaired people.

“Here we demonstrate a fully 3D-printed hemispherical photodetector array that can sensitively detect images with a wide field-of-view,” Ruitao Su, a research assistant at the University of Minnesota who worked on the project, told Digital Trends. “The high efficiency of the photodetectors and the ability to readily customize the size and layout of the design render this approach … promising for the creation of bionic eyes.”

To make the device, the researchers began with a hemispherical glass cone, which they used as a sort of canvass to 3D print an array of photodetectors. Silver nanoparticles were used as conductive interconnections, and a couple layers of semiconductive components helped convert light into electricity. Finally, liquid metal was used to print cathodes on top. The whole process, which took about an hour, is pretty complicated but still generates a relatively primitive prototype.

Ideally, the researchers want to be able to print on a soft material, such as tissue, that can be implanted into a real eye. That means they have a lot of work ahead. Their next steps will include scaling down the size and improving the performance of their 3D-printed photodetectors, such that they can compete with commercial ones, and develop the image sensors to support a comprehensive vision system.