Considering that the last mammoths died out 3,600 years ago, they’ve had one heck of a 2018 so far. First, there was Harvard University’s plan to resurrect the woolly mammoth using gene-editing technology. Now, a Belgian 3D-printing company, Materialise, is putting its skills to the test by helping to create a life-size replica of a mammoth skeleton for public display.

The 3D-printed re-creation is of the Mammoth of Lier, the first mammoth ever displayed in Western Europe, which was first shown off to the public in 1869. “Because the original skeleton had to stay in Brussels, Kiwanis, a local service club, had the idea to re-create the skeleton with modern technology,” Bram Smits, public affairs officer for Materialise, told Digital Trends.

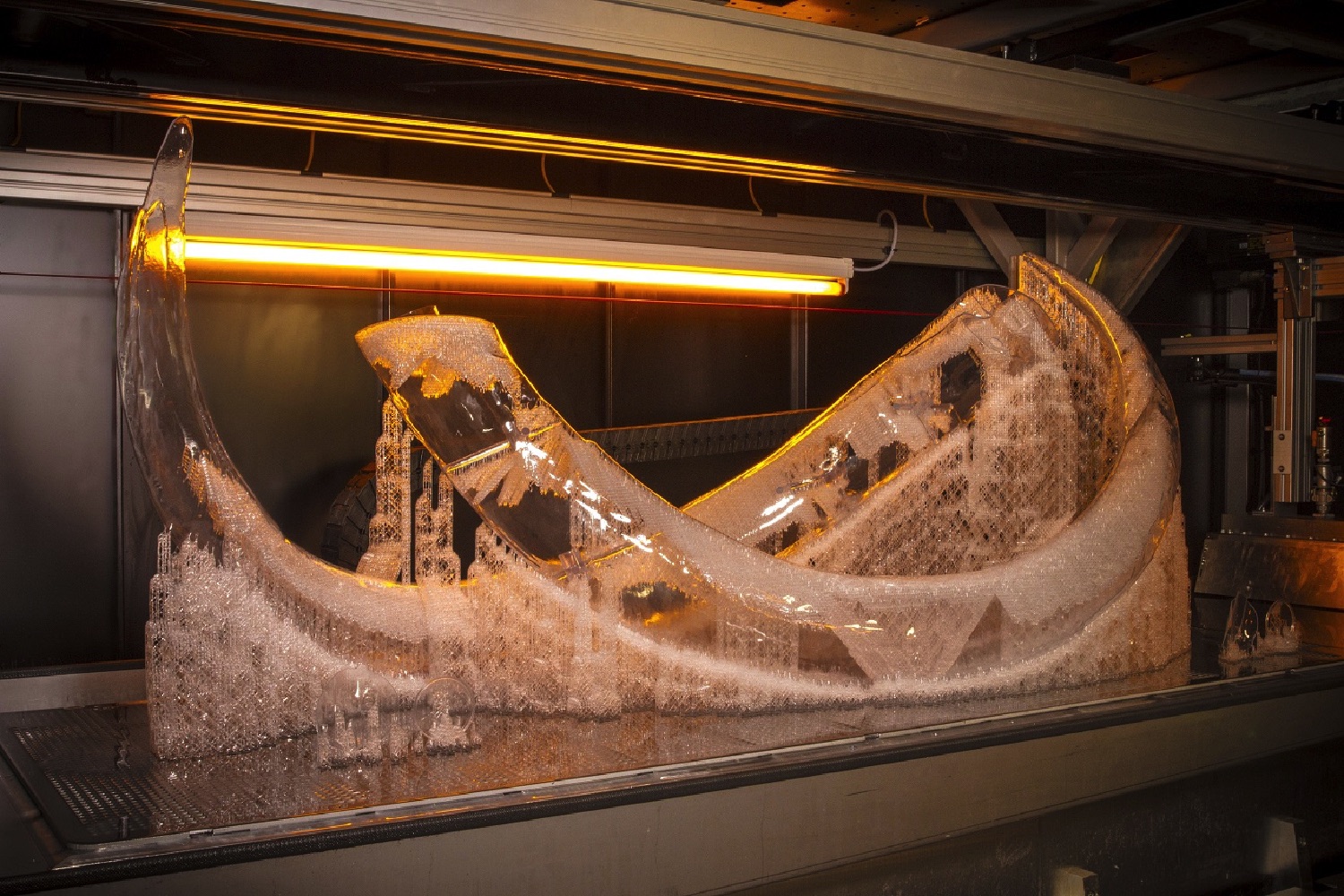

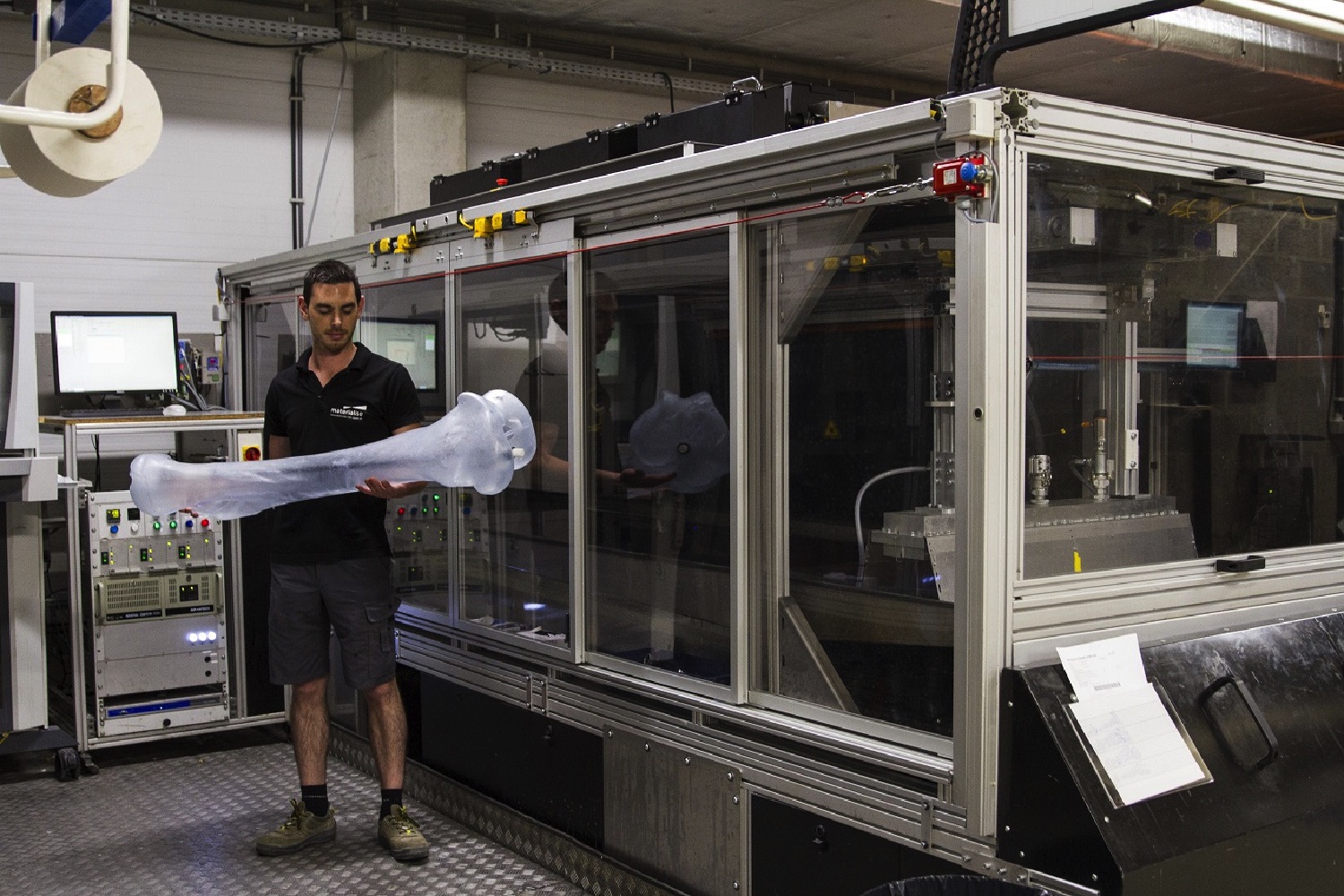

To rebuild the iconic mammoth, the Materialise team had to 3D scan a total of 320 bones, which were then printed on (appropriately named) Mammoth Stereolithography printers. The pieces are now due to be painted with a combination of paints, textures, and lacquers to make sure the printed pieces match the original bones as closely as possible. The finished mammoth model will be put on display in the city of Lier, Belgium, in October.

“Obviously, the scale is a lot bigger than most of our projects,” Smits continued. “We’ve developed our own printers in-house to be able to print prototypes from dashboards and bumpers for the automotive industry in one piece. With 15 of these printers in our production facility in Leuven, we had that part covered, although we never dreamed that one day we would actually print a mammoth on our Mammoth printer.”

Dr. Mietje Germonpré, from the Royal Belgian Institute of Natural Sciences, who served as an adviser on the project, told us that work such as this represents an exciting step forward for paleontology.

“[The] 3D printing of precious fossils means that the original material does not have to be handled,” Germonpré said. “An accurate and precise 3D print is as good as the original object to study scientifically. Secondly, a virtual reconstruction can be sent, 3D printed, and studied all over the world, without the need of scientists to undertake long travels in order to gain access to the fossil. An interior structure hidden inside the fossil that can normally be attained only by breaking the object can be printed and examined while the original fossil remains complete. Finally, missing parts or bones of a skull or skeleton can be virtually reconstructed based on the preserved paired elements.”