We may be years away from 3D printing being used to bioprint full organs which can be used in transplants to save lives, but make no mistake about it: additive manufacturing is already helping people.

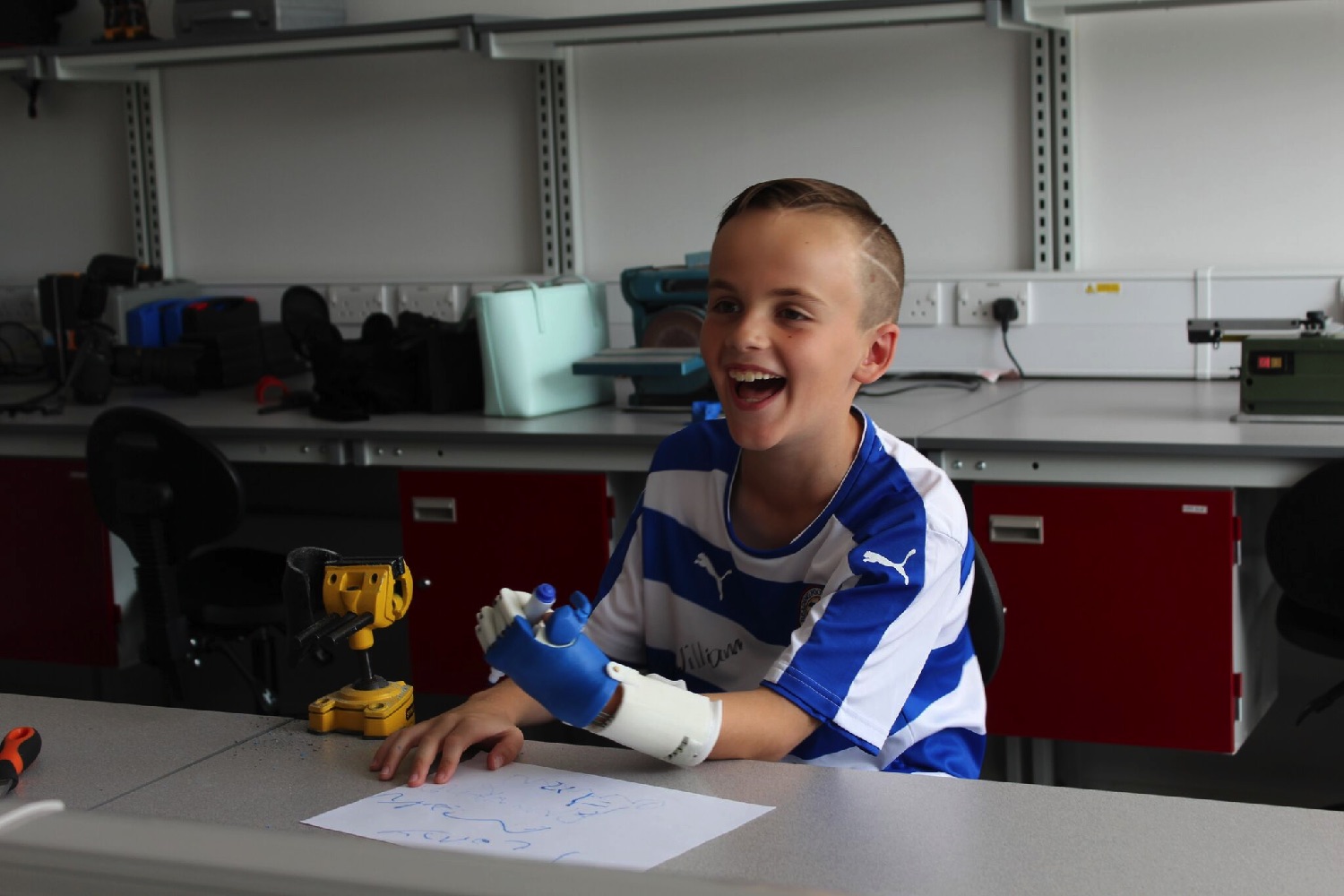

This month, an eight-year-old British boy named William Joyner, who was born without a left hand, received a 3D-printed robotic prosthesis that lets him grip objects and even hold a pen.

“Within a few minutes of having it on his hand, William had picked up a marker and was drawing a picture and signing his name,” Professor David Jazani, a senior lecturer at University of Bedfordshire — who helped create the prosthesis — told Digital Trends. “While he was doing this I glanced across at his mom, and her eyes were full of tears. That’s when we realized just how worthwhile this work is.”

According to Professor Jazani, William’s mother first got in touch with the university after reading a story online about a 3D-printed prosthesis, and believing that similar technology could transform her son’s life. Professor Jazani worked with technician Mark Hooper to build the piece.

An initial prototype was first developed earlier this year, although it was only this week that a more robust final model was completed and presented to William. “[The first prototype] worked, but it was also extremely fragile,” Jazani said. “Some of the plastic parts in it were just 1mm thick. Its material, ABS plastic, has a lot of benefits, but it also has downsides — such as the fact that when it’s exposed to sunlight it starts to erode and becomes a lot more brittle. In all likelihood, [the first prototype] would have broken in a matter of hours. We needed a way to make it more robust.”

Not only did the final version of the prosthesis meet this criteria, but Jazani and Hooper even 3D-printed it in the blue and white colors of William’s favorite soccer team. It should be usable by William until he is in his teenage years.

“One of the most important things about 3D printing is that it lends itself so well to rapid prototyping,” Jazani concluded. “Previously to make a part, we’d have had to create a mold and do injection molding. It was a lengthy and very, very expensive process. With 3D printing all of that changes. It’s very exciting.”