The rail gun is portable and fires just like a real gun, but with six capacitors that weigh a combined 20 pounds, it’s absolutely monstrous in comparison to a conventional rifle. Armed with these six capacitors, the gun (dubbed the WXPR-1 by its creator) delivers about 1050 volts and 1.8 kilojoules of energy to the projectile inside the gun.

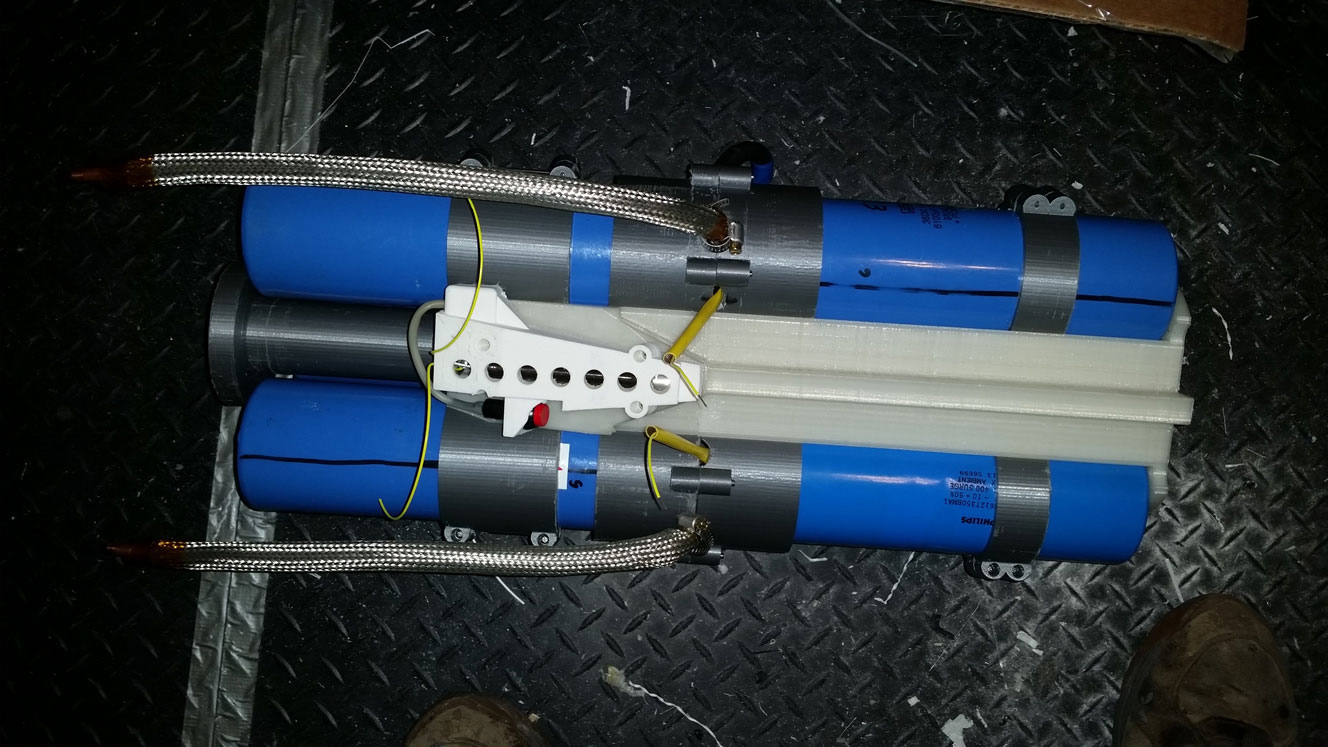

To make the weapon portable, these capacitors are bundled into in three pairs of two and held together in a 3D printed frame, which is then attached to the bottom of the railgun body. As expected, it delivers one heck of punch when fired, and actually vaporized a carbon projectile in one of xtamared’s first test runs.

The gun’s electronics are controlled by an Arduino Uno R3, which monitors the levels of the electronic components — including the capacitor voltage, the amperage, the temperature, and battery voltage. The entire unit is powered by a 12V lithium-polymer battery that’s stepped up to 1050V using a micro-inverter and a transformer. It fires a variety of metal armatures, such as copper-plated tungsten, aluminum, carbon, and Teflon/plasma.

Video footage of the gun firing is pure awesomeness. The aluminum sabot flies out of the gun at 250 meters per second (559 mph), hits a plywood target with a steel backing approximately three feet away, and bounces off the wood after leaving a 1/2-inch deep indent. The carbon test was much more impressive from an audiovisual point of view, however, setting off a loud arcing sound and a discernible spark as the carbon projectile flew out of the gun and disintegrated.

Lest you think you could build one on your own in the next week, xtamared said he did a ton of research before he had enough knowledge to build the gun. He used information he gleaned from PhysicsThings micro-railgun and Sam Barros’ Powerless railgun design. It then took him about a year and a half to complete the project, with about six months to fine tune the electronics, six months to machine the rails, and another six months for the 3D printing, remaining design, and final assembly. The end product is nothing short of amazing.