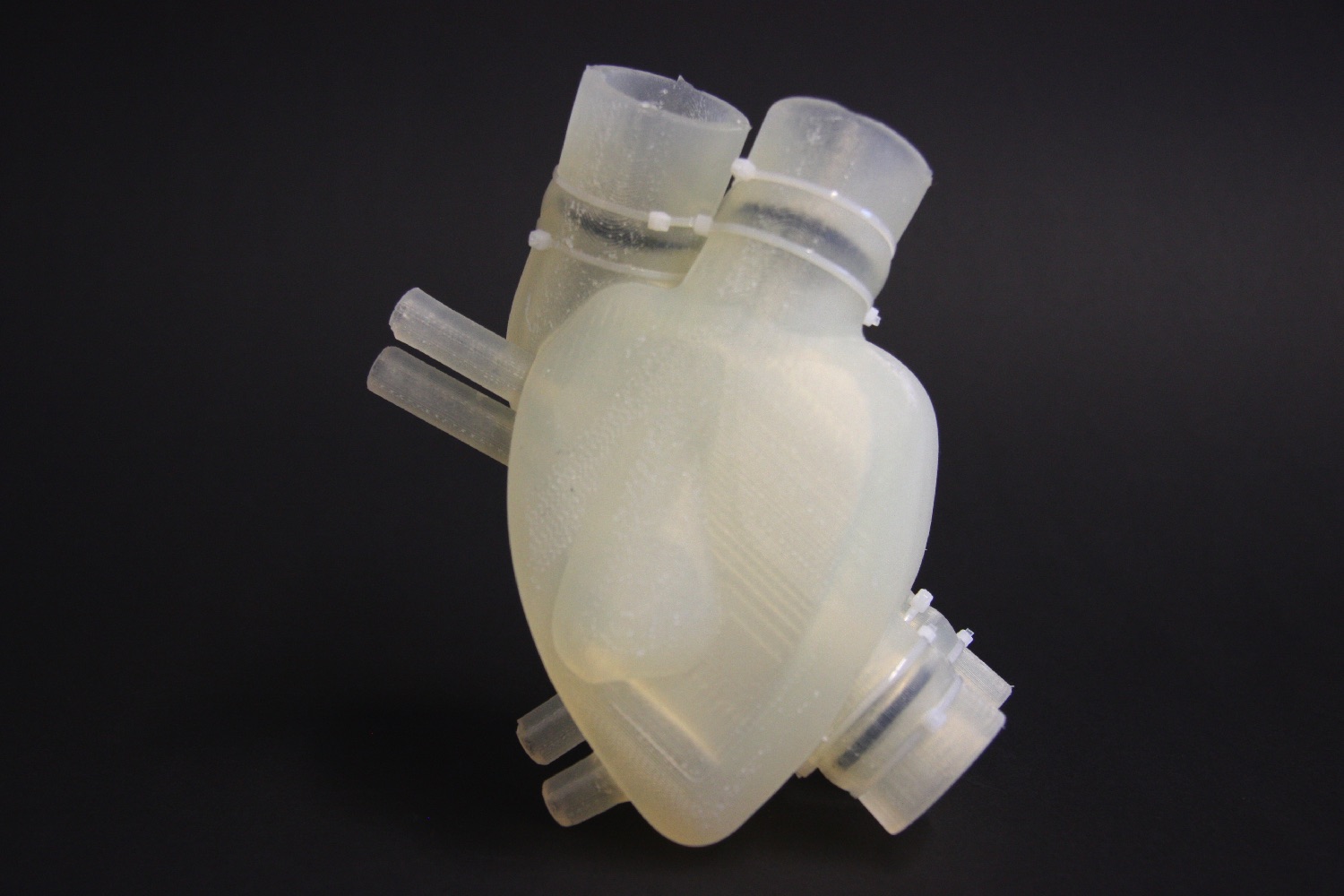

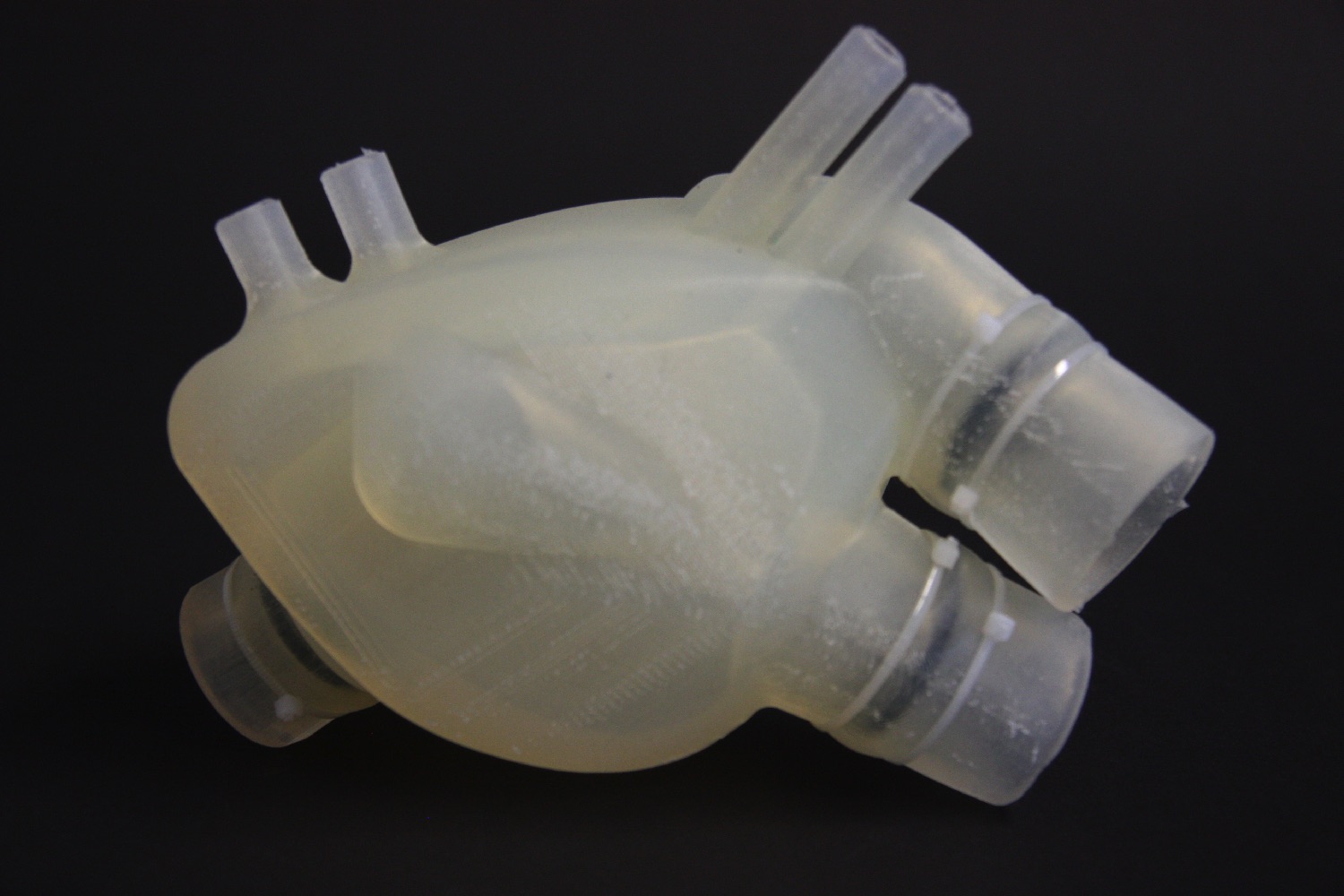

A new project at Switzerland’s ETH Zurich is going physically bigger than that, though. What scientists there have developed is a functional beating heart — made of silicone, using a 3D printed mold — which represents one of the most advanced replicas yet created of one of our most important organs.

While not a biological replica of the actual heart, the idea is that it could be used as an artificial heart in scenarios such as when a patient is awaiting a heart transplant.

“I met with a heart surgeon, Professor Volkmar Falk, now head of the largest heart surgery clinic in Europe, at the Charité [teaching hospital] in Berlin,” Wendelin Stark, professor at the Institute for Chemical and Bioengineering at ETH Zurich, told Digital Trends. “He asked me if we could think about a new artificial heart. I had no clue at first. Then we learned that current heart support machines are made of hard materials like steel or titanium and plastic. When a patient receives such a hard device, its blood tends to make clumps — so the patient is given a so-called ‘anticoagulant,’ a drug that reduces blood clot formation.”

Stark said that, despite everyone’s best efforts, the result can mean serious problems for patients — ranging from strokes to lung problems to intestinal bleeding. “It was astonishing to find out that the anticoagulation therapy was the largest single cause of problems in patients with heart implants,” he continued. “We realized that a soft implant might allow this to work without such blood-thinning agents.”

Because of Stark’s history with 3D printing, his team decided to make a 3D-printed mold, which could then be used to create a silicon rubber heart.

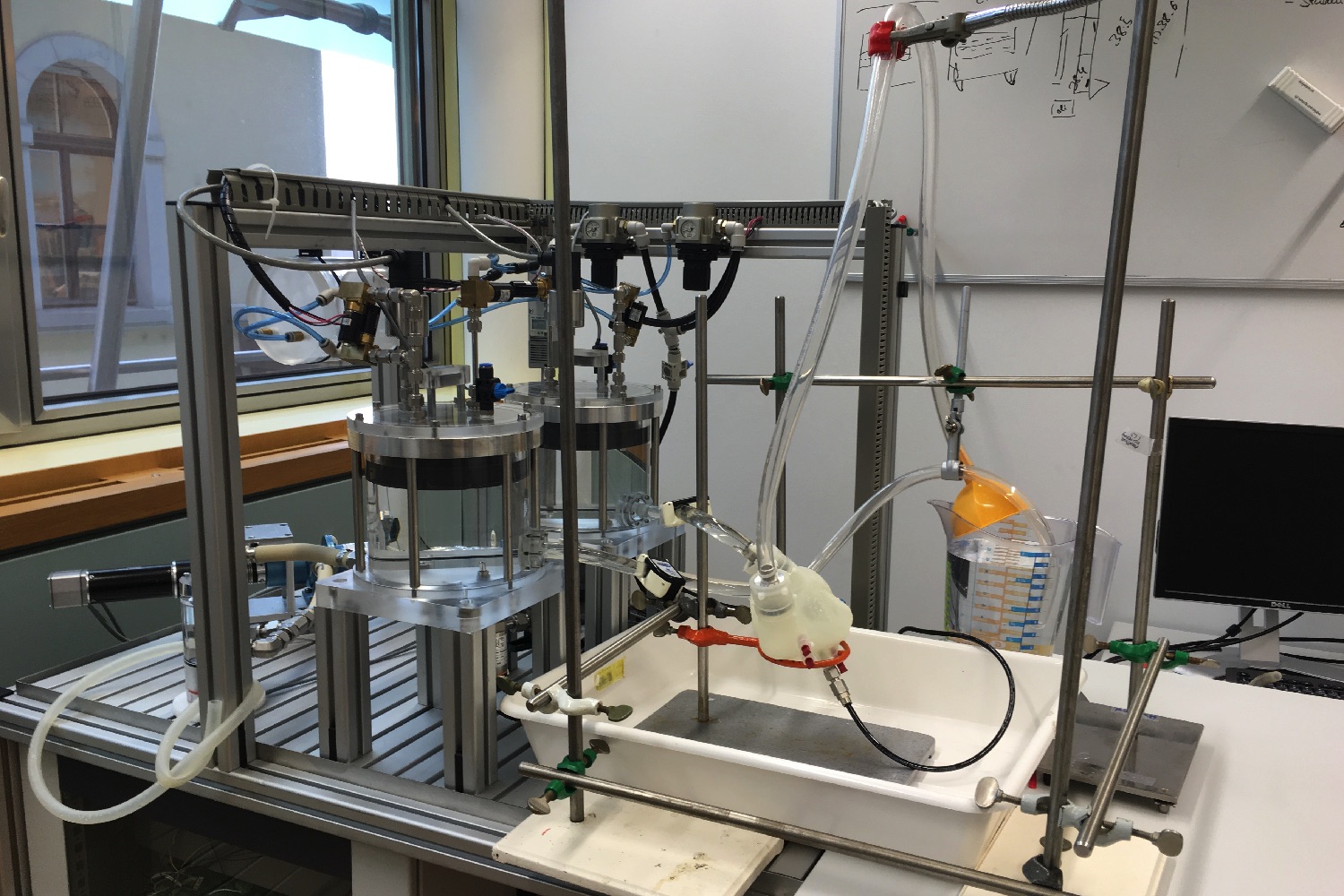

“We used the mold to make silicon soft pumps, and optimized the design to fit a human heart-type pumping pattern,” he said. “We teamed up with Mirko Mebolt, a mechanical engineer, and tested the prototype against a human-like blood flow resistance.”

The current model is promising, but not yet stable enough to be used in an actual patient. At present, it only works for several thousand beats, lasting around 30 to 45 minutes. Over time, Stark said the plan is to develop a model which could conceivably work over a period of years.

That, to use the technical term, is what might be known as a “game-changer.”