“When I first got my 3D printer, I sent a message to my brother asking if there was anything he could think of for me to make,” Wu told Digital Trends. “I didn’t want to print off the kind of tiny knickknacks that most people print, I wanted to do something different. My younger brother suggested making a mechanical counter. Through the research on what that might mean, he discovered a video describing how the Curta works. I was immediately fascinated. As soon as I saw the video, I began planning out how it would be possible to 3D print something like that.”

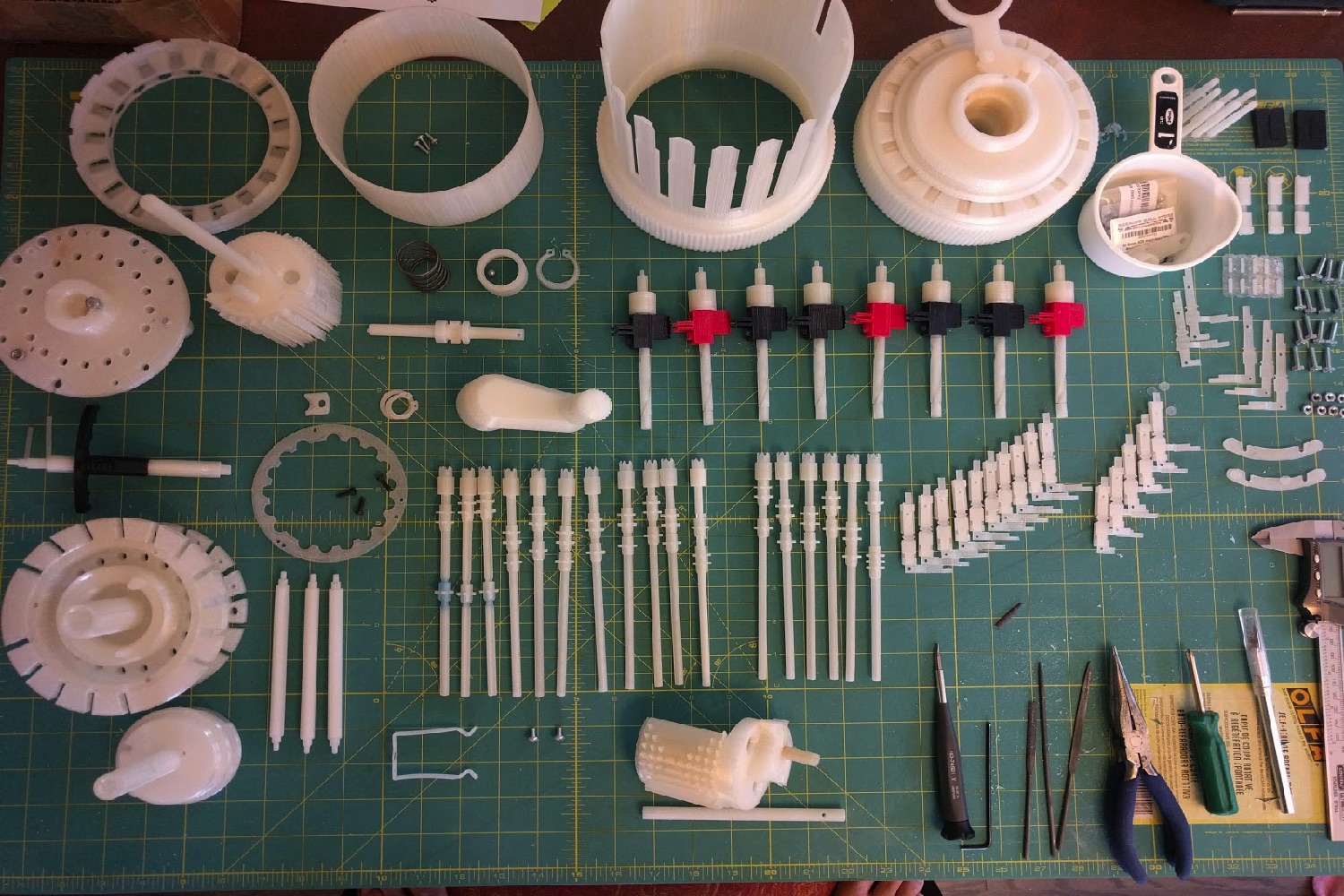

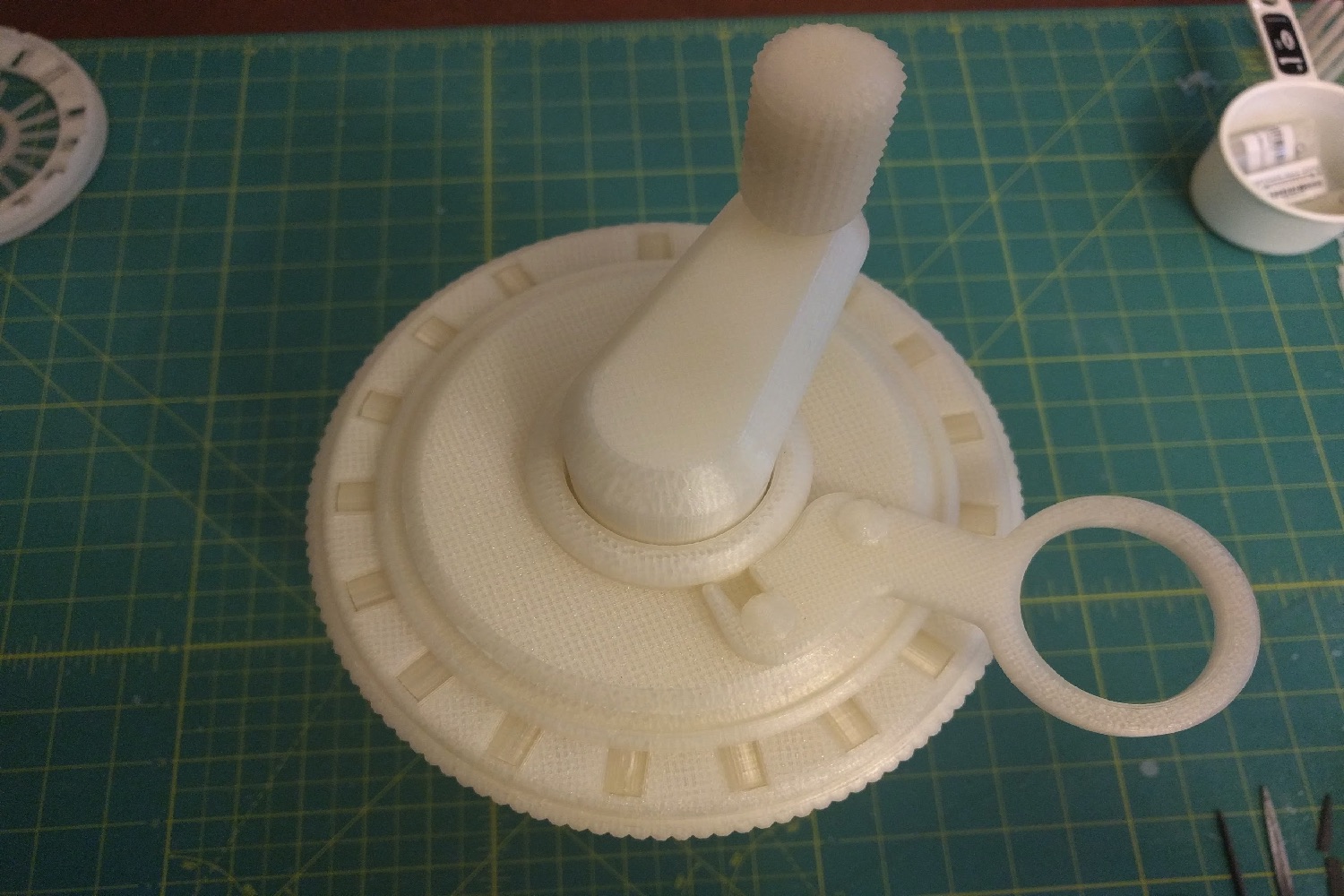

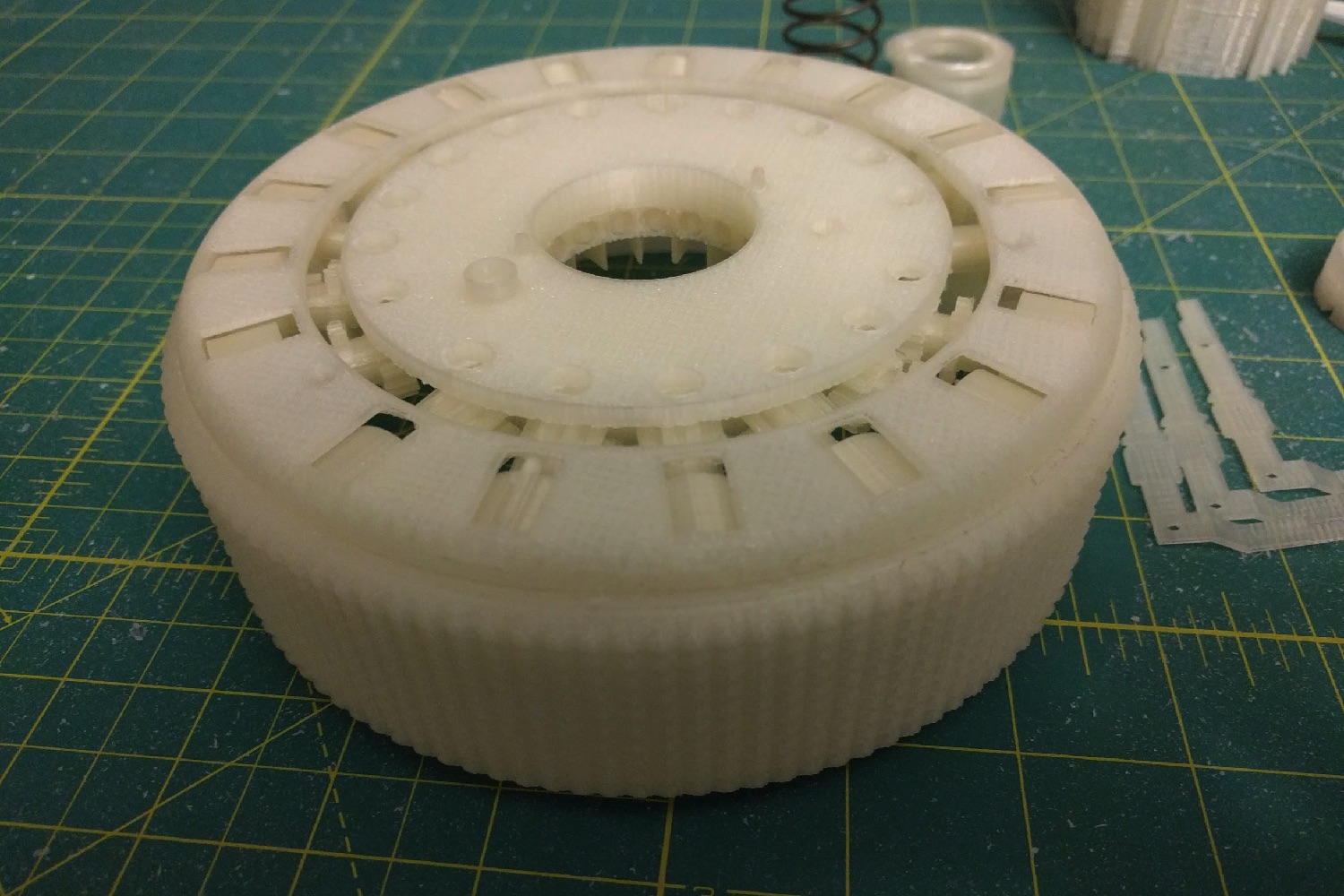

Wu documented the subsequent process on his blog, which describes all the challenges he encountered in building his 3:1 scale model, 3D-printed Curta using a gMax 1.5 3D printer. Considering the scale of the project, which required the printing of 240 different parts, along with 100 extra unprinted pieces like screws and ball bearings, it’s no surprise that the epic project took 18 months to complete.

The next step will be exhibiting the finished piece at the Charlotte Mini Maker Faire on October 8

People wanting to build their own Curta can also benefit from Wu’s hard work — eventually.

“I will be making the files available,” he said. “I haven’t done that yet because there are certain aspects of the Curta that require you to make specific tools to put them together. There’s a whole process I’m going to have to write up in a tutorial. The files themselves wouldn’t be terribly useful without the additional information. I didn’t just want to release the files and leave people scratching their heads. I wanted to really give people everything they need to build a Curta of their own, start to finish.”