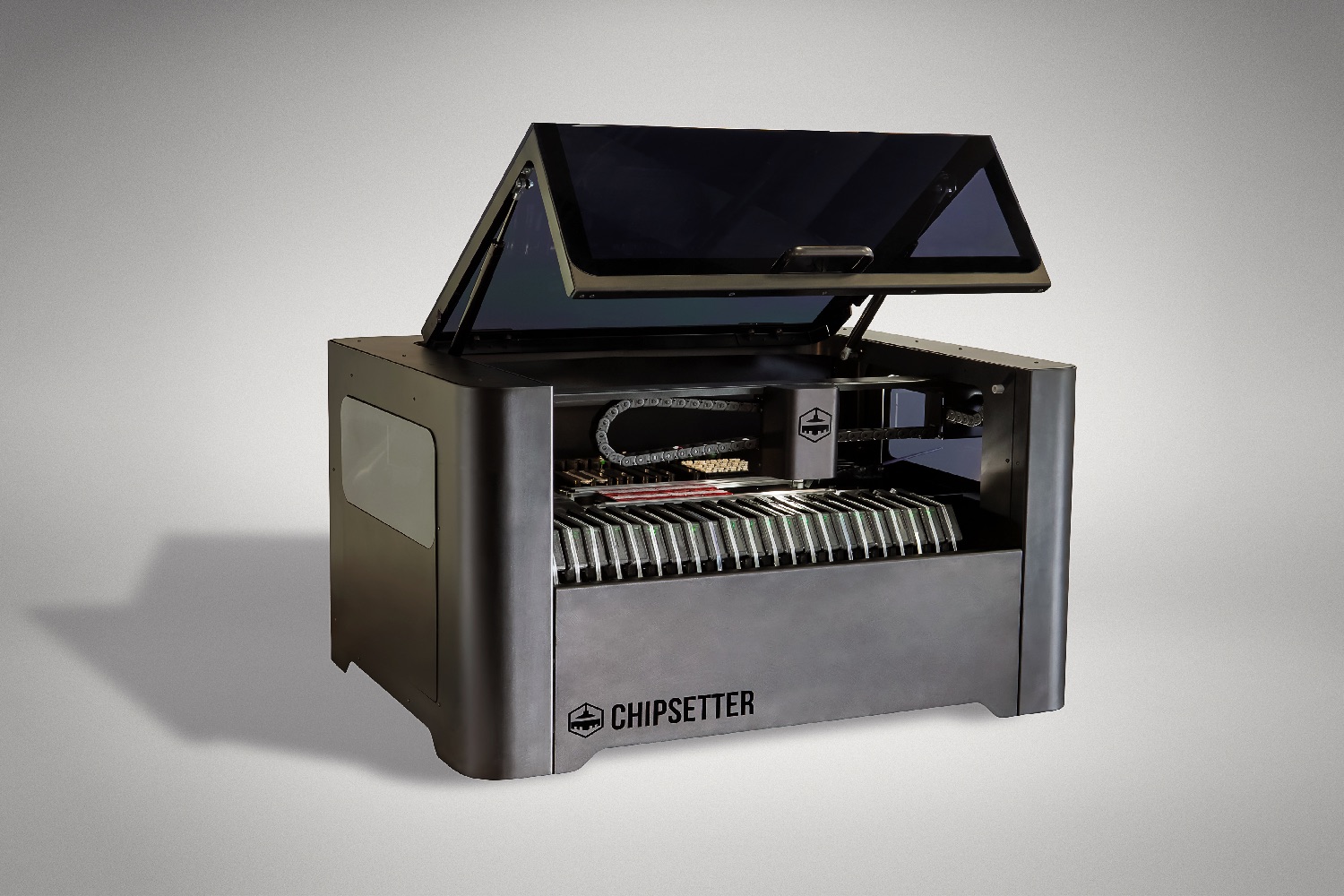

Now, after more than two years of development, the company Chipsetter is ready to introduce a new breakthrough class of device, with what it is claiming to be the first industrial-grade desktop pick-and-place machine designed for modern innovators.

“What we’ve done is to develop a desktop pick-and-place machine, which is one of the most useful machines you can imagine when it comes to assembling circuit boards,” founder and CEO Alan Sawula told Digital Trends. “This is an increasingly difficult task, because the components that are coming out are getting smaller and smaller. You can use a pair of tweezers if you need to make one board, but if you have to make 20 you really do need a robot to do it for you — and they start at around $60,000. This represents a big step forward for electronics developers.”

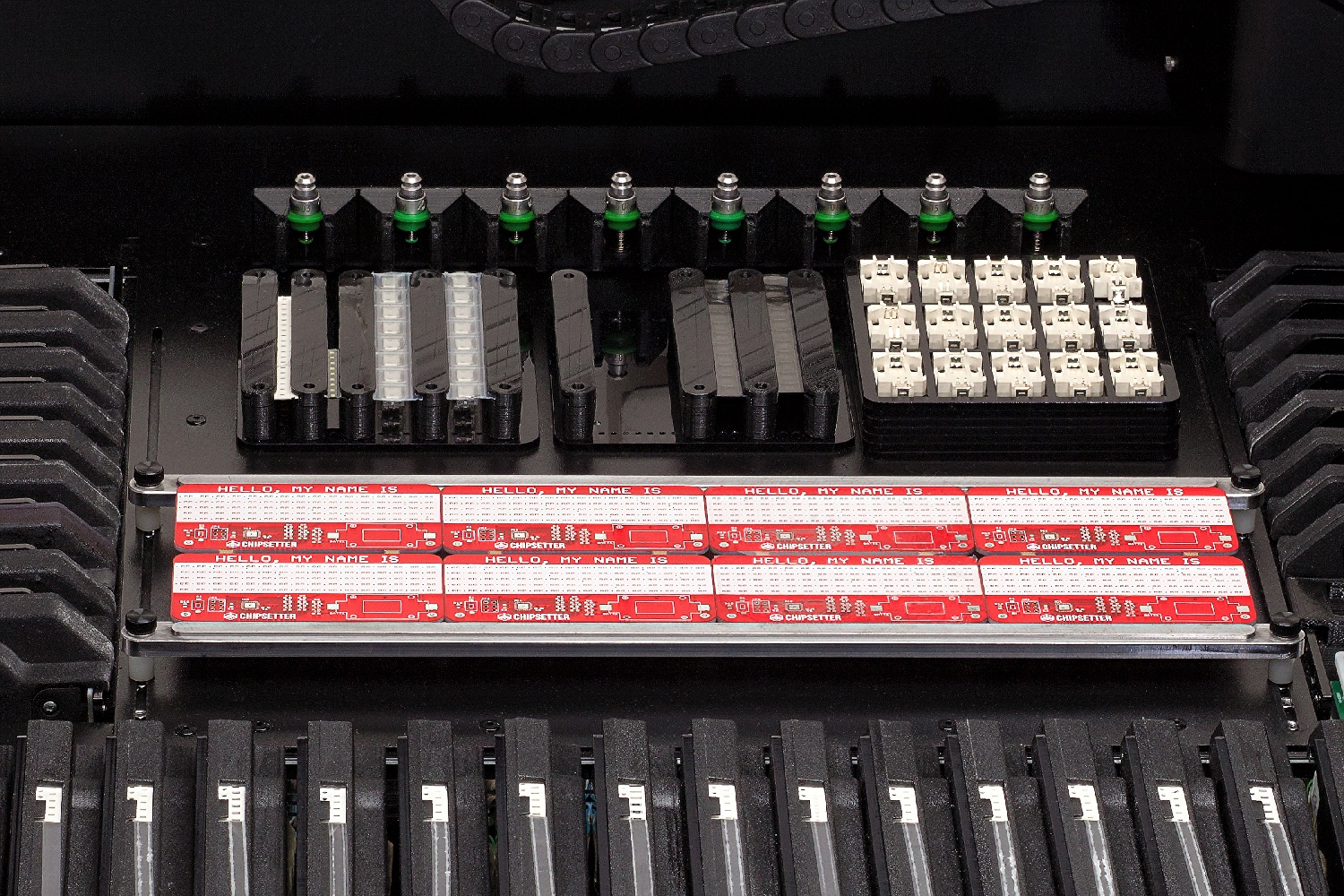

What the Chipsetter One does is to give makers of small batches of electronic devices a means to make rapid prototypes of printed circuit boards. Able to place 1,250 components per hour, with a high level of repeatable placement accuracy, and capable of printing board sizes up to 13.5-inches x 10-inches, this is the perfect solution for home electronics enthusiasts.

The project is currently looking to raise $140,000 CAD ($105,000 U.S.) on Kickstarter, with a Chipsetter One available to preorder for $5,999 CAD ($4,500 U.S.). Orders are planned to ship in September 2017.

“One exciting thing this does is reduce the cost of failure, which boosts innovation because it means people can try more iterations of a concept,” Sawula said. “Over the next few years, I think we’re going to see a wealth of open-source hardware designs available on the internet. There’s going to be a shift to making electronics not just in factories, but more locally and with greater customization. Before too long, these machines are going to be things our children are using at school to build their science fair projects. It’s really going to be beyond a lot of people’s wildest dreams.”