Guess which application Marel, a.k.a. the leading global provider of high-tech food processing systems, is most interested in!

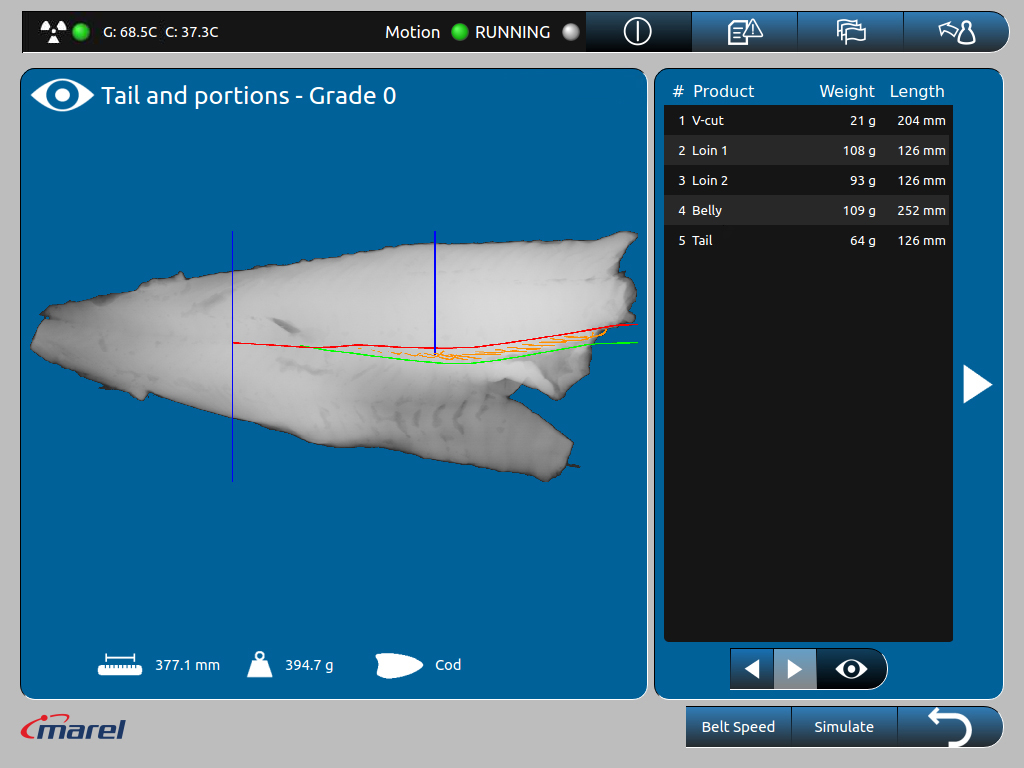

Named the FleXicut, the company’s new robotic fish filleter has been described as the fish stick maker Tony Stark would have in his home. It’s an astonishing piece of machinery which uses X-ray bone detection to pinpoint the location of pinbones with an accuracy of 0.2mm. It then uses advanced software to determine exactly the right cut configuration and angle, before utilizing water-jet cutting for bone removal and portioning the fillets according to specification.

“There are certain parts of the fillet that are more valuable than others,” Stella Björg Kristinsdóttir, Marketing Manager for Marcel’s fish industry products, tells Digital Trends. “The loin is very valuable, while the belly part is not so much. The pinbone lies in the most high value part of the fish. You need to cut very close to it in order to maintain as much high-value protein as possible. It’s a very skilled job for a human to carry out. We wanted to automate that.”

The FleXicut is just the latest example of skilled food-related tasks being carried out by machine. Other high-profile examples include IBM’s Chef Watson, which can use ‘cognitive cooking’ technology to create entirely new recipes, and Momentum Machines, which has built a hamburger-making machine that can spit out made-to-order burgers at an impressive rate. For its part, Marel’s FleXicut can fillet 50 fish per minute: taking less than one second to decide exactly which cuts need to be made.

Now if we could just get our hands on a rice making robot and one for seaweed wrapping, we’d have all the ingredients for a perpetual sushi machine! We can dream, can’t we?