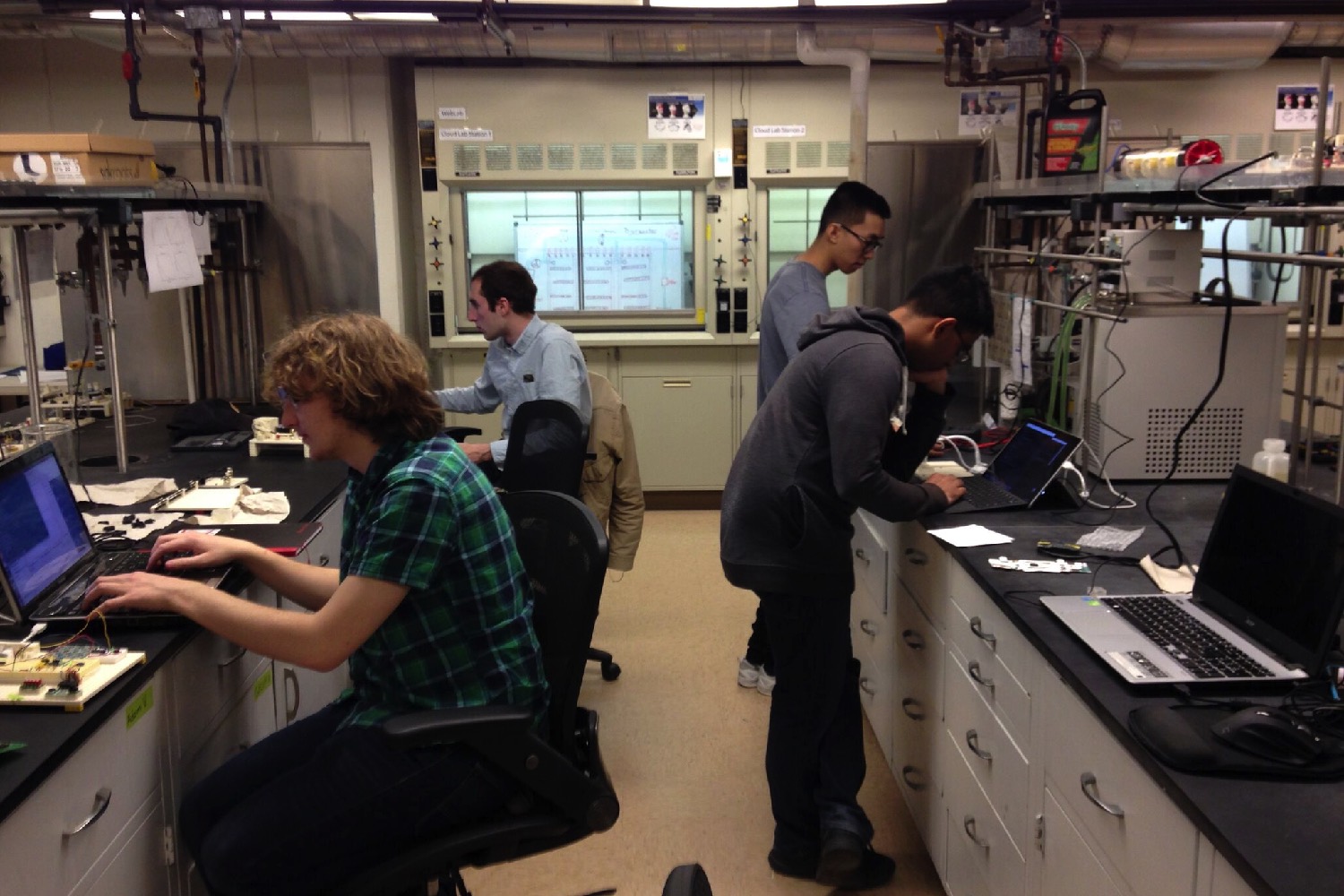

“[Right now,] if you want to do a lot of different things in science, you need a lot of different instruments,” William Grover, assistant pofessor of boengineering, tells Digital Trends. “That makes research really costly and inefficient. We end up with rooms full of instruments that do relatively little. So, inspired by LEGOs, we set out to make a set of building blocks that can be used to build research instruments. Researchers could use these blocks to build virtually any instrument they might need. They could even invent completely new instruments.By giving researchers the tools they need, faster and more cheaply than conventional methods, the blocks will hopefully speed up the pace of scientific research.”

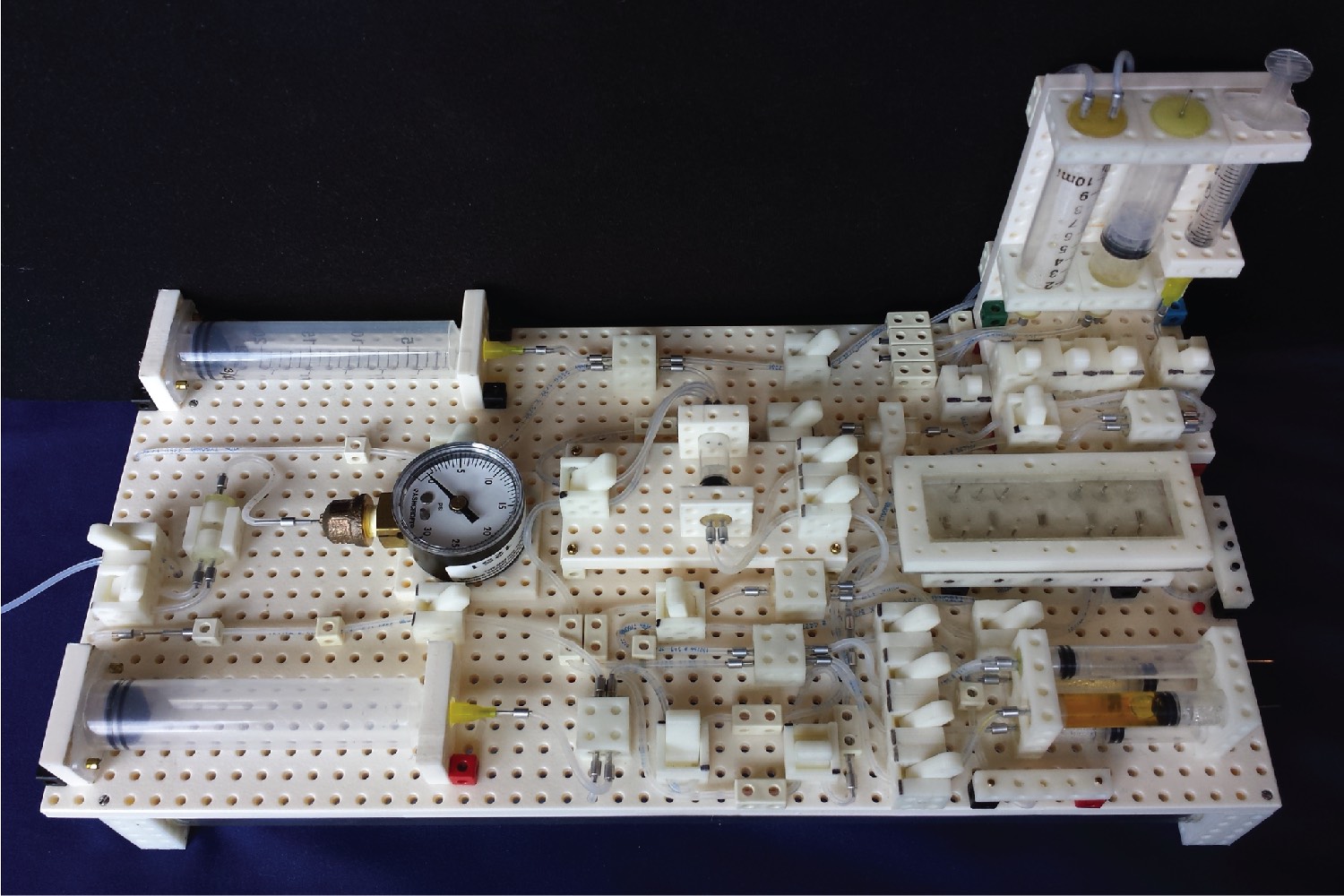

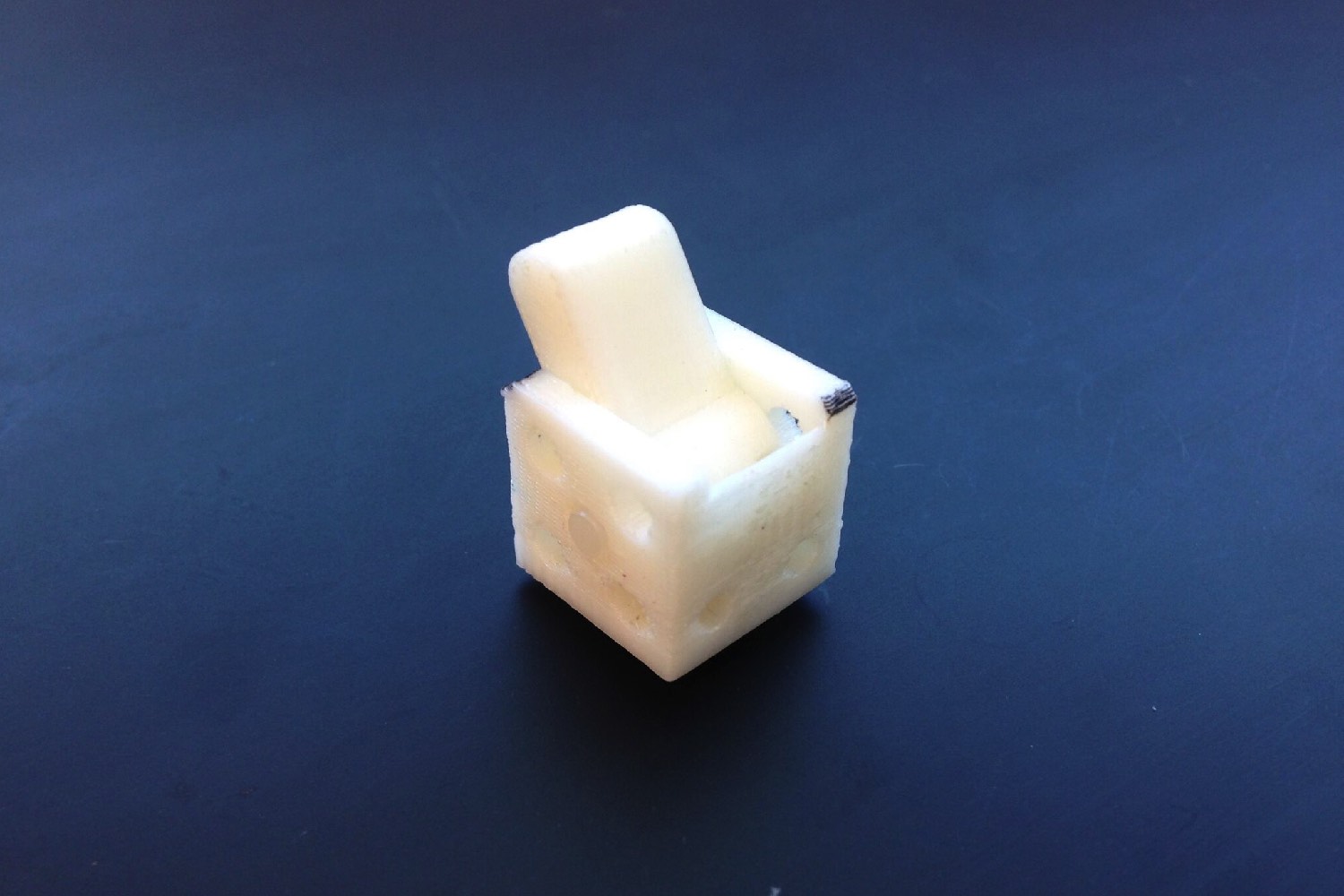

Called MECs — short for Multifluidic Evolutionary Components — the blocks definitely represent a unique use of 3D printing, combining cutting-edge technology and a bit of engineering to create versatile pieces capable of acting as anything from compact bioreactors to acid-based titration tools for high chemistry classes.

As with different Lego pieces, each block in the system performs a different task found in a lab instrument, whether that be pumping fluids or taking measurements. By putting them together in different configurations, it’s then possible to utilize them in a variety of ways.

“One of the most exciting possible applications for the MEC blocks is in resource-limited settings,” Grover continues. “Imagine a doctor treating patients in a remote clinic that’s far away from a conventional hospital. This doctor would love to have a room full of diagnostic instruments like we have in a big hospital, but these instruments are too expensive, too big, and too power-hungry to put in her clinic. But if the doctor had a set of our MEC blocks, she could possibly build whatever instrument she needs to diagnose and treat a given patient. Having a set of MECs would be like having access to a huge variety of instruments, even if you’re in the middle of nowhere.”