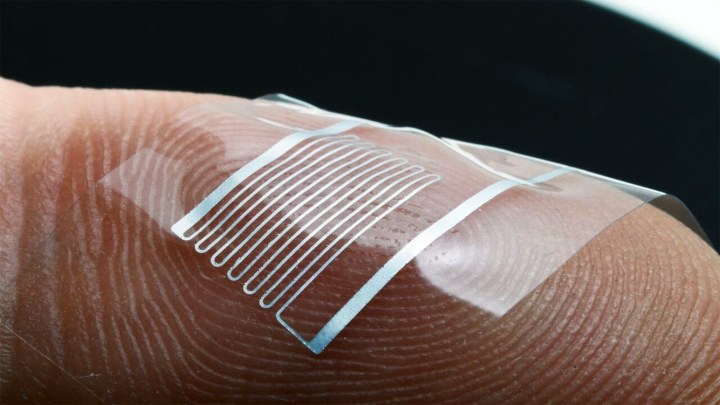

Thus far, creating sensor-studded textiles has proven extremely difficult, since hardwired circuitry doesn’t allow for a whole lot of flexibility. The EPFL material, however, can be stretched to four times its length a million times, without damage to the integrity of the material and its embedded circuitry. A stretchy polymer film serves as the base for an ultrathin layer of liquid metal alloy. Since the polymer itself is stretchy and flexible, only a liquid metal could facilitate conductivity without keeping the material rigid. The alloy is made up of gold and gallium, which remains liquid at room temperature so it can still conduct the current in a circuit while the polymer is manipulated or stretched.

This isn’t the first time that scientists have tried to manipulate liquid metal in this way, but its high surface tension has always resulted in thick, rigid materials. That’s why the EPFL researchers had to come up with a new approach: “Using the deposition and structuring methods that we developed, it’s possible to make tracks that are very narrow – several hundredths of a nanometer thick – and very reliable,” said Stéphanie Lacour of the EPFL’s Lab for Soft Bioelectronic Interfaces.

The liquid metal material is a working prototype, but it is still in a very early research stage. EPFL expects the polymer to appeal to the wearable technology industry, and designers on both sides of the rising fashion-technology trend. Further in the future, flexible circuit-laden polymers like these could be used in more technological settings, like medical applications in temporary skin sensors and as artificial skin to cover the frames of the robotics industry.