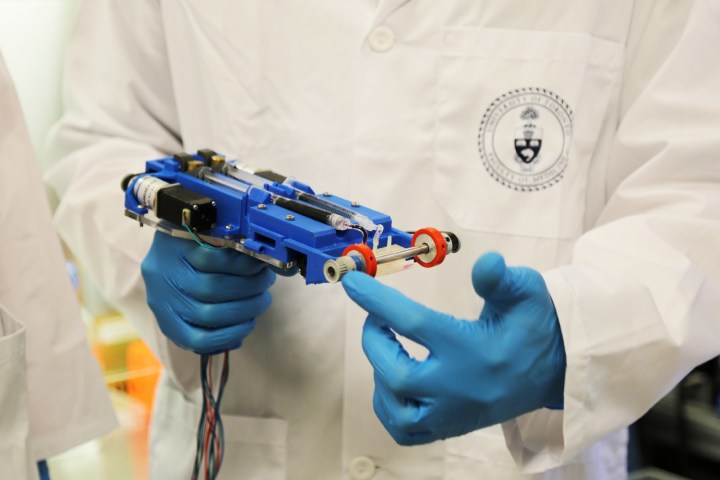

Imagine a version of the kind of duct tape dispenser you can buy from your local home Home Depot or white-out tape used for correcting a writing error — only instead of rolling out pieces of tape or white-out material it can produce a sheet of skin tissue to cover a wound. That may sound a couple of phasers away from being a Star Trek gadget, but it’s a very real piece of research coming out of the University of Toronto. Engineers there have developed a 3D skin printer that can apparently, “[form] tissue in situ, depositing and setting in place, within two minutes or less.”

According to its creators, the device could serve as a future alternative to regular skin grafts. However, instead of first requiring that a patient has healthy skin removed to be grafted elsewhere, this device can roll out a new layer of “bio ink”-based, 3D-printed skin tissue onto the areas that are required.

Unlike existing bulky bioprinters, this device is portable and weighs just over 2 pounds. Wounds could be patched up in the space of just a few minutes, and the gadget requires very little training to use. While it has yet to be tested out on humans, it has already been shown to function when patching up both rats’ and pigs’ wounds.

“In collaboration with Dr. Marc Jeschke from the Ross-Tilley Burn Centre at Sunnybrook Hospital, we for now focus on burn injuries,” Axel Guenther, an associate professor in the University of Toronto’s Mechanical and Industrial Engineering Institute of Biomaterials and Biomedical Engineering, told Digital Trends. “The handheld instrument may ultimately allow engineered skin tissues to be prepared that are wound and patient specific.”

At present, Guenther said that the team responsible for the device is busy conducting wound-healing experiments to benchmark their approach against established alternatives. Going forward, he said that the researchers are interested in commercializing the technology, and are working to develop it to this stage.

A paper describing the research, titled “Handheld skin printer: In situ formation of planar biomaterials and tissues,” was recently published in the journal Lab on a Chip.