“Just pick up your cell phone, look at the face without any power or image, and you’ll see a pretty good example of what today’s thin film looks like,” John Conklin, CEO of SolarWindow, told Digital Trends. “It’s heavy, it’s too dark to see through, and most thin-film is not flexible. This type of technology isn’t the type to build skyscraper windows.”

He, on the other hand, had a different idea.

This is where SolarWindow comes into play. As the term “regular windows” suggests, users don’t have to replace the existing windows in their home, but need only treat them with a special process developed by the company.

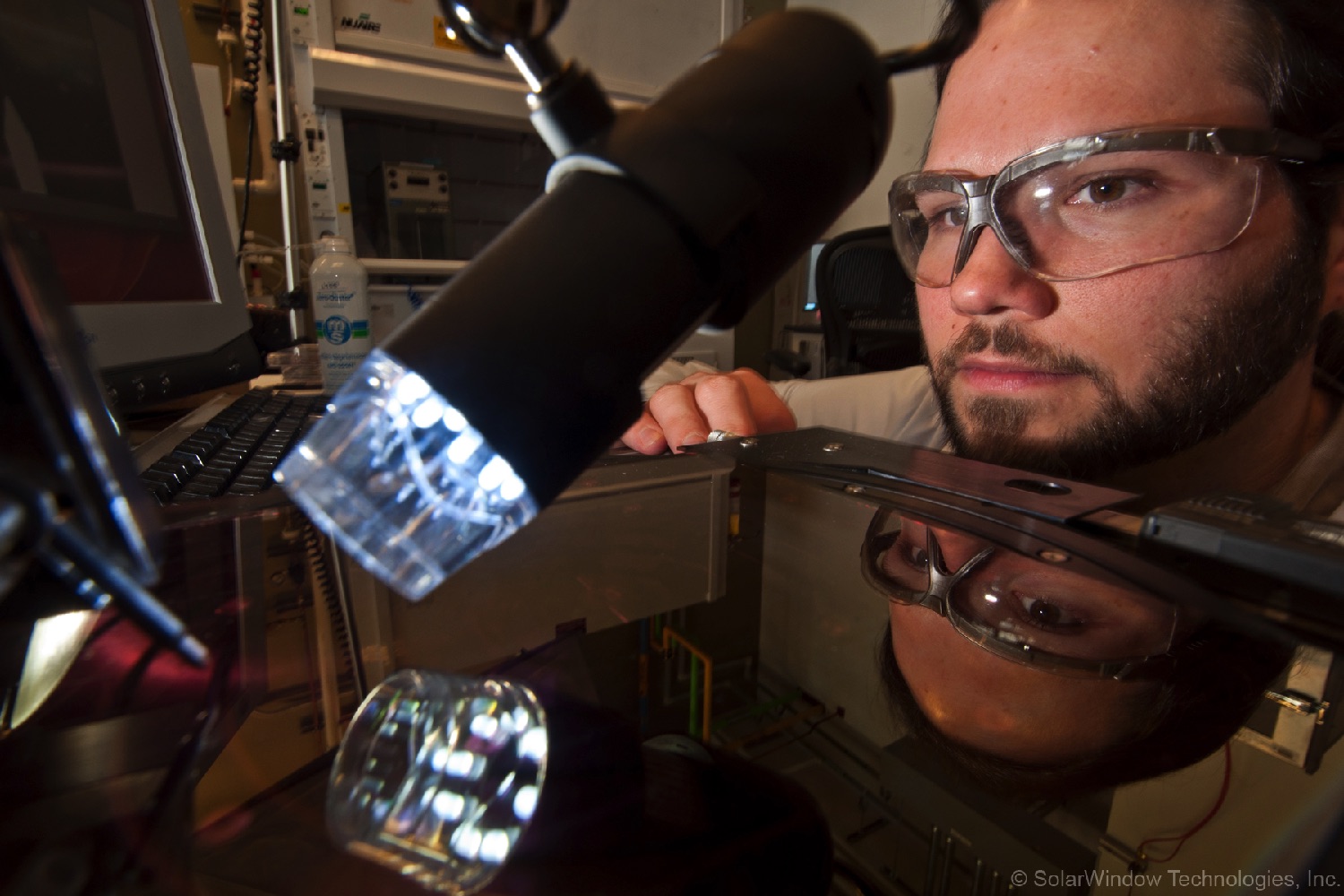

“We apply liquid coatings to glass and plastic surfaces at ambient pressure, and dry these coatings at low temperature to produce transparent films,” Conklin continued. “We repeat these processes, and then collectively these coatings — and thus the glass and plastic surfaces — generate electricity.”

Of these coatings, the most important is the so-called “Active Layer,” through which electricity is generated by the absorption of light, and the transparent conductors, which allow the electricity to be extracted. “[The] coatings are primarily organic, primarily from carbon, hydrogen, nitrogen, and oxygen,” Conklin said. “We are constantly refining each of the layers to improve on the power we’re able to extract from these coatings and enhance their manufacturability.”

In addition to buildings, Conklin notes that some of the possible applications of this tech include the automotive industry, where a sunroof, windscreen or even side view mirrors could be turned into solar panels. There are also aerospace and military use-cases, and even the possibility of a “flexible fabric” being developed.

In all, it’s an exciting area to be working in, with some impressive math on its side. What kind of math? By the company’s estimates, a 50-story building with solar windows could generate around 1.3GWh every twelve months. For those keeping track, that’s enough energy to power around 130 homes for an entire year.