If you had banked on strawberry-picking as a potential career after your current job is taken by a robot, we have some bad news for you: That’s probably not going to be an option for much longer. In the U.K., robotics experts at the University of Essex have teamed up with a British jelly manufacturer to find ways to train robots to pick strawberries on farms.

Their rationale is that U.K. farms currently waste around 20 percent of their soft fruit due to problems recruiting enough workers. This situation could potentially get even harder after Brexit, which is why there’s a need to find alternative ways of harvesting this fruit.

But just because picking fruit is an easy task for humans doesn’t mean the same is necessarily true for machines.

“The main challenge is the unstructured dynamic nature of the problem,” Vishuu Mohan, a professor in the School of Computer Science and Electronic Engineering at Essex, told Digital Trends. “Berries grow with time, come in different shapes, sizes, order of ripeness, and the environment cannot be fully controlled. In such conditions, solving the identification or ‘what could be a ripe berry,’ localization or ‘where is it in space,’ and motion planning or ‘how do I move to reach, grasp, and cut it’ [problems] are the main challenges.”

Considering that a human can pick a berry in a fraction of a second, the robots the team is developing will have to exhibit an impressive amount of precision, speed, and other traits to compete. It can, however, be done. In the past, we’ve covered robots designed to pick everything from cucumbers to tomatoes. Meanwhile, a Belgian engineering company called Octinion is working on similar strawberry-picking tech, which it aims to have in around 100 greenhouses worldwide by next year.

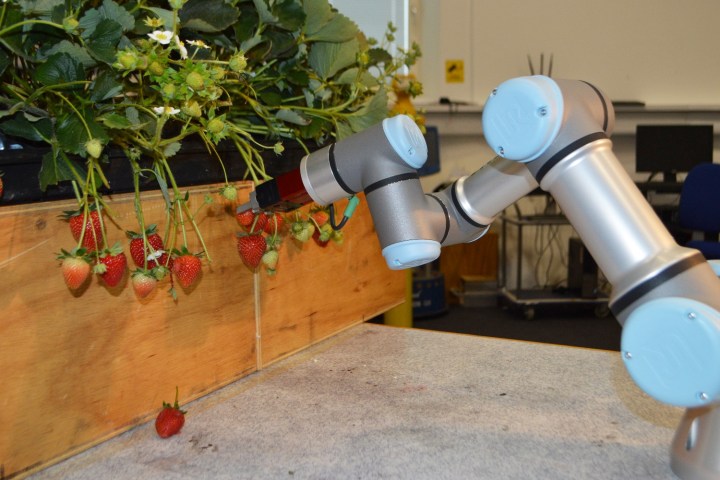

At present, the University of Essex researchers have developed a robot that’s able to accurately identify and reach for berries, with the next step being to build an end effector that can cut stems as required. A prototype is expected to be unveiled in the next several months.

But while this may seem yet another quasi-depressing chapter on the road to total workplace automation, Mohan is more optimistic. “Contrary to the notion that ‘robots are taking jobs,’ they are actually not in this particular case, and humans can move higher up in the value chain — for example controlling the robots, [and] managing the logistics,” he said.