With autonomous and flying cars on the horizon, there’s a whole lot that we’re excited about in the automotive world. But ask us on a frosty Monday morning in darkest winter as we’re scraping the ice off our windshield while muttering curse words under our breath, and you’ll find us to be a lot less enthused. In those moments, the car-related technology we want more than anything else in the world is a frost-resistant windshield.

Fortunately, researchers from Virginia Tech appear to have heard our agonized prayers. With this precise goal in mind, they have invented what they claim to be the world’s first passive anti-frosting surface, which is capable of staying 90 percent dry and frost free in frigid conditions. And all without the need for chemical or energy inputs to make it work.

“Everyone is familiar with the concept of laying salts down on the ground before a big snowstorm,” Jonathan Boreyko, assistant professor in the Department of Biomedical Engineering and Mechanics, told Digital Trends. “Salts are a hygroscopic chemical, which means that they are a very good humidity sink, capable of sucking up nearby moisture and water to keep the surrounding surface dry.

“However, there are two big problems with using salts to combat icing. First, as the salt crystals absorb water from the air and surrounding ice, they become diluted and quickly lose their hygroscopic properties. This is why we have to lay down salt over and over again, to the tune of about 10 million tons per year in the U.S. alone. Second, the practice of laying down salts has been well-established to contaminate the environment, especially the groundwater.”

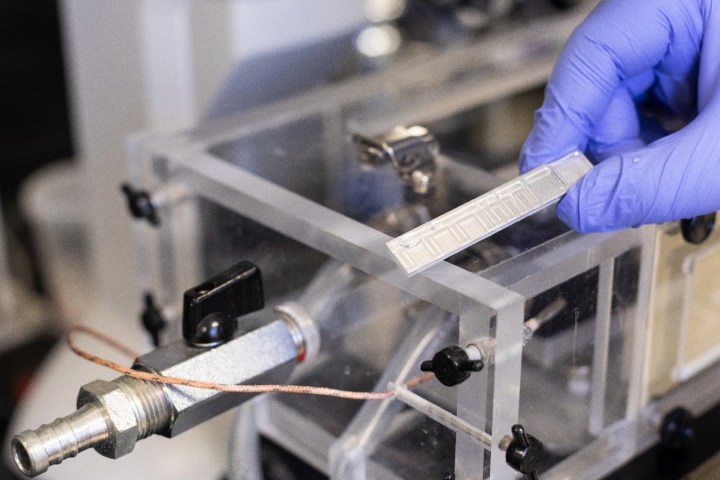

What the Virginia Tech researchers have done is to take this concept of using a hygroscopic chemical to minimize frosting as a starting point. But instead of using salt, they machined patterns of micro-grooves into the surface of sample material they created. These microscopic grooves function as sacrificial areas, creating stripes of intentional ice when it is freezing. Because ice has the same low-pressure properties as salts, the intermediate areas between these stripes stay completely dry from condensation or frost, since the humid air is instead attracted to the ice stripes.

“We are currently in serious talks with both aerospace and heating, ventilation, and air conditioning (HVAC) companies to see if we can apply this technology to airplanes or the outdoor heat exchanger of heat pumps,” Boreyko said. “The heat pump idea, for example, would involve patterning the ice stripes on the array of micro-fins that are already on the outer portion of an outdoor heat exchanger, to keep the interior of the unit dry from frost.”

A paper describing this research was recently published in the journal ACS Applied Materials & Interfaces.