Well, get ready. Tech titan LG brought Digital Trends along on an exclusive tour of several of those sites halfway around the globe — and we’re opening the doors and bringing you inside with us.

Make no mistake: Much of what we saw was confidential information, of the “I could tell you but I’d have to kill you” sort. But we can share enough to give you a rare peek behind the curtain.

Putting it all together

Flying to Asia is terribly boring. It’s 5 hours from New York to Los Angeles, and half a day further from there to Korea. Watch three 2-hour movies back to back and you’ve still got 7 hours to occupy. Sleep for 3 hours and you’ve got 4 hours to go. It’s breathtakingly dull. But arrive in Seoul, South Korea’s capital city, and you’ll revel in a completely different culture.

After leaving the airport, we drive an hour south of the city to LG’s Pyongtaek facility, passing dozens of apartment complexes, each with 15 or 20 high-rise buildings. Each campus is big enough to be a city itself – dormitories for tech companies in some cases, based on the names in 30-foot-high letters that identify individual buildings. The scale of the city is simply enormous. It stretches on and on and on. There are 10 million people in the metropolis of Seoul; it is twice as dense as New York.

Pyongtaek is a mammoth office complex – a reminder of the sheer number of people responsible for making that cell phone you carelessly toss in your bag at the end of the day. And in one area of this campus is a smartphone assembly line, an airplane-hangar-sized room so clean it’ll make your teeth hurt.

Think about this: To make a CPU from raw chemicals or fabricate a piece of motherglass that individual screens are cut from requires a room so clean that dust doesn’t exist. The clothing you wear, the minute particles in your hair, are enough to ruin a wafer that cost thousands of dollars. Assembling phones doesn’t require the same clean-room environment as delicate CPUs, but it requires precautions nonetheless. We dropped our coats and bags, put on white lab coats, and wrapped our shoes in soft cloth booties. Pictures were strictly forbidden.

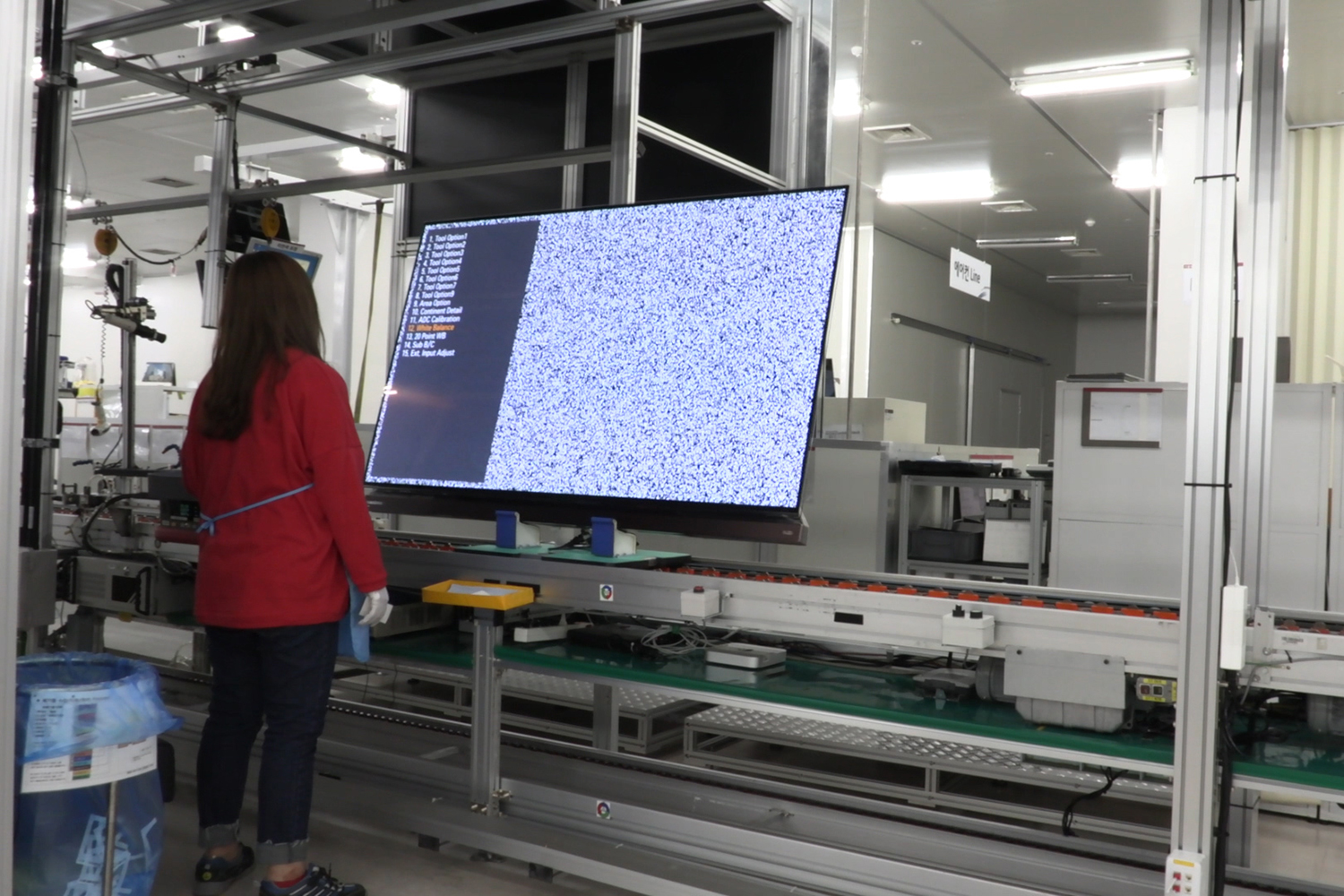

On benches and desktops sit the exposed guts of panels, connected to test machines that monitor their output.

LG’s assembly lines are designed to be modular; they can assemble high-end smartphones like the V20 or mass-tier models like the X power. On the day we visited, the line was churning out a model only for sale in Korea. Phones move along conveyor belts from machine to hand to machine again, as circuit boards arrive and are screwed in place. The actual assembly seems mundane: An individual worker may only plug in a power cord or repeatedly fasten the same two screws on phone after phone after phone.

Every 20 feet or so a conveyor belt carries the phones into enormous machines that bake them, test screens to ensure quality, and so on. Workers also visually inspect the phones to ensure that they are defect-free. The bar is high, and the rate of production errors is closely watched. I asked how many they’ve spotted that day alone, and they laughed at me.

No errors had come up recently, but some examples to watch for were on display at a nearby table. A dozen or so phones had tiny blemishes, screws that weren’t seated correctly or flawed circuits. The flaws were almost impossible to see by eye.

Paju, where TVs are made

The smartphone assembly line was fascinating, but we went to Korea to see big screens, too. So we headed to the Paju Display Cluster, one of LG Display’s enormous campuses and the world’s largest display manufacturing hub. It’s located at the very northern edge of South Korea, almost on the border with North Korea.

To reach it, we drove an hour north of Seoul on a highway that follows the Han River, which flows south out of the Democratic People’s Republic of Korea and into the greater Seoul area. A fence topped with concertina wire runs its length, preventing entry to the South via the waterway. Guard towers dot the length of the river – a reminder of the world we live in.

The Paju complex is made up of eight enormous buildings each seemingly larger than an airport terminal that sit on 420 acres. A ninth, called P9, is currently under construction. When completed, it will be the world’s largest OLED manufacturing plant. More than 17,000 people work at Paju, many living in enormous residential complexes on site. There are movie theaters, and grocery stores. There is a basketball court.

Of all the trade secrets LG Display has, what goes on inside of these buildings is the most secret. The products being created will earn billions; cameras – indeed, outsiders in general – are strictly forbidden. We were shown a variety of tomorrow’s technologies, proprietary stuff we weren’t allowed to share. And there was always something else: An entire showroom was roped off. We stood in a room to see next year’s products; behind us was an entire wall of something, covered by sheets. Go figure.

Instead, we flew on the LG helicopter an hour south to the Gumi facility, where LG assembles televisions. It was especially big: Picture several warehouses fused together, a warehouse to store other warehouses. doesn’t require the clean-room garb we donned for phone assembly. Indeed, it is lower tech than you might expect. Because technology changes so rapidly, assembly lines are designed to be modular. They look impermanent, almost transient, the sort of thing you would put together yourself if someone told you to make one.

Conveyor belts rolled along as straight as an arrow the entire length of the room, perhaps a quarter mile. Screens came down from the ceiling to workstations where arms, either robotic or human, attached the few circuit boards required to transmit and process the picture. Some of the mechanisms were ingenious – a machine that sorts screws and rolls them one at a time down a chute – and others are Rube Goldbergs, things that don’t appear that they could possibly work but clearly do. There were suction cups, for gosh sake — LOTS of them. And these machines themselves are closely guarded trade secrets? How strange.

Notable are the varied ways cardboard boxes and foam were packed. For some screens, this was a simple process: Drop the television into the box, angle it forward, drop in a manual, wrap it in packing tape. Rinse. Repeat. Others required a few pairs of hands to ensure that everything was seated correctly.

Along the way, the panels entered dark rooms where expert eyes ensured correct output and flagged any defects. It takes perhaps 10 minutes for a panel to enter the chain and leave as a television. And before shipping out, each is stored in a separate room and left running for days to ensure that no problems crop up.

Where products are perfected

The TV screen you watch Stranger Things on is more than just a blank canvas; the engineering work that goes into honing and improving future versions of it is nothing short of remarkable. We went back to Pyongtaek to learn a little about some of that work.

Much of what we saw was confidential, of the “I could tell you but I’d have to kill you” sort.

Up an elevator, down a corridor, and past a vast room where engineers tweak televisions, we saw benches and desktops filled with the exposed guts of TV panels, connected to test machines that monitored their output. Experts made infinitesimal changes to the chemicals that go into the surprisingly skimpy things, and carefully monitored the results.

Across the hall from all of those engineers was a room as black as night. Inside it, research engineers studied color accuracy, brightness levels, and viewing angles. One shortcoming to many LCD panels is pronounced shift in color at wide viewing angles: If you sit on the couch to the side of your TV instead of head on you’ll probably notice it. LG’s latest OLED panels emit exhibit almost no color shift even when viewed edge on. (A demo we were shown half a dozen times really underscored that point.)

Companies like LG take picture quality very seriously. LG’s 2016 OLED sets achieve 96 percent of the DCI-P3 color gamut, a space that describes the range of colors the television is capable of displaying. That’s almost all of them, in other words, but unsatisfying to the meticulous engineers we spoke with, who believe they can improve further for next year’s models. We talked with a half-dozen research engineers about steps the company is taking to improve color range even further.

As we left, we passed rooms where appliances are tested – refrigerators designed to hold other refrigerators so LG can test a fridge’s performance at a given temperature, and devices that drop phones from a specific height over and over or mash buttons thousands of times. One machine is essentially an enormous jeans-wearing ass; what happens if you sit on a particular phone 50,000 times in a row? In a sealed room in a sealed building in Pyonktaek, South, Korea, one engineer will soon know the answer.

Improving sound by destroying it entirely

Image quality is all well and good, but don’t underestimate the importance of audio. To measure and hone it, LG built an anechoic chamber in the Pyongtaek facility. Anechoic chambers are specially designed to absorb sound waves, thanks to chunky angles of foam, absorbent materials, and so on. Stand inside one and your entire reality shakes for a second; your body relies on echoes and sound for balance, you see. When you close the door to the chamber, it’s unsettlingly quiet.

Clap your hands inside an ordinary room and the sound echoes around, bouncing off the desk nearby, maybe reverberating back from a corner or the glass of a picture frame. In this chamber, there’s nothing: Clap your hands and the sound dies instantly after, leaving you waiting for sounds that never arrive. Even the floor is strange. An open wire mesh sits a foot or so above more foam. Weird doesn’t do it justice.

LG says it excavated ground beneath the chamber to ensure that it sits vibration free. Separate power and climate control systems are housed in a closet outside, along with computers displaying spectrometers that measure sound pressure levels within the chamber. It’s all very impressive.

Down the hall is another lab, where audio is tested more subjectively. It’s an ordinary living room, mundane to be honest, with hundreds of thousands of dollars worth of reference speakers from brands that audiophiles crave: Kef, B&W, Dynaudio. A $50 Bluetooth speaker may not be able to compete, but manufacturers test them out against the best nonetheless.

Inside the idea factory

Seocho District is a small part of Seoul, South Korea’s capital city, which is a bustling giant. There are fewer neon signs than in New York or Tokyo, but It looks largely like any other big city – dozens of businesses dot the streets, ads are stacked vertically on buildings, and signs in English as well as Korean.

And people. There are hundreds of thousands of people. We stopped for street food at a busy market, elbowing past crowds to a stand selling steaming buns full of pork and vegetables. Something on a stick sits stacked on a plate; we drank cups of hot liquid that looked like tea but turned out to be broth.

On an ordinary street in this metropolis lives the Seocho Research & Development facility. It was born in 2009, and over 3000 people work there, giving birth to high-tech ideas from a glimmering pool of silicon and ambition. And as such, it’s one of the super secretive facilities that LG guards closely: Admission to Seocho meant forfeiting cell phones and laptops, signing non-disclosure forms, and so on. Indeed, we were only allowed to record a short video outside of the building.

A parking garage sits across the street from it; a sign there touts used cars. Oh, and here’s a fun fact: Seocho is part of Gangnam District — yep, that guy. In fact, there’s a well-known sculpture dedicated to Psy and his Gangnam Style song just down the street from our hotel. Whoop THAT.

Within the facility and its Innovation Lab, inventors turn raw ideas into the next big thing, whether they’re smart doorbells, self-steering vacuum cleaners, or next-generation display technologies.

And unfortunately, that’s all we’re allowed to tell you.