“It just happened to be the thing with all the attributes we were looking for in a building material,” he tells The New York Times. “Who knew hemp would be the answer to what we were looking for?” Made from the inner woody part of hemp plants (hurds) plus lime and water, hempcrete is a good insulator (Savage says he’s insulated his walls with hempcrete and no longer needs air conditioning), flexible, mold- and pest-resistant, and nearly fireproof. And you can’t smoke it, as the strain used in the building material contains only 0.3 percent THC, while medicinal and recreational varieties have 5 to 10 percent.

In addition to its potential energy savings, hempcrete is green in other ways: Growing and harvesting the hemp sequesters the carbon dioxide that would otherwise be released during decay, making it better than carbon-neutral.

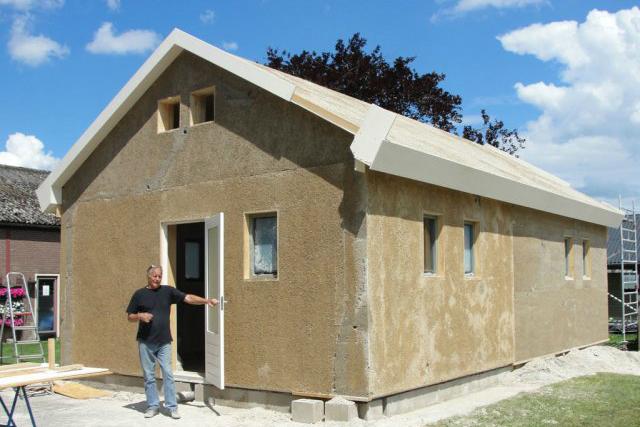

While one problem with hempcrete is that it requires thicker insulation than other building materials, a larger problem is that growing hemp was criminalized in the 1930s. While a recent farm bill allows some hemp-farming pilot projects, they haven’t yet started up and builders wanting to use hempcrete need to import the raw material, according to The New York Times. Meanwhile, its use is fairly popular in Europe. It was developed in France in the 1980s and even insulates a home Prince Charles built.

There are a few architects and contractors who use hempcrete here, including Tim Callahan, who built America’s first hempcrete home in 2010. Savage thinks it’s high time hempcrete becomes widely used and wants to start making shippable, modular tiny houses out of the material.