Rechargeable batteries are used in so many different products that we use today – everything from our computers and mobile phones to our cars have batteries inside. One of the major areas of research is in new battery technologies that will increase the run time of electrical devices and make safer batteries.

Rechargeable batteries are used in so many different products that we use today – everything from our computers and mobile phones to our cars have batteries inside. One of the major areas of research is in new battery technologies that will increase the run time of electrical devices and make safer batteries.

Lithium-ion rechargeable batteries have been on the market for a long time and are prone to problems. The batteries, for instance, were the cause of massive recall several years ago after they were overheating in notebooks which in turn caused fires. One of the more promising new battery technologies being researched are zinc-air batteries.

These batteries are cheaper and have a significantly larger capacity for storing energy than existing lithium-ion batteries. Physorg reports that the average lithium-ion battery stores only a third of the energy that zinc-air batteries are capable of storing and cost about twice as much as the zinc-air counterpart.

A Swiss company called ReVolt plans to release a zinc-air battery next year. At first, the batteries will be small units that will be used in hearing aids. Later the batteries will come in larger forms for mobile phones and much later, the zinc-air battery will find its way into electric vehicles.

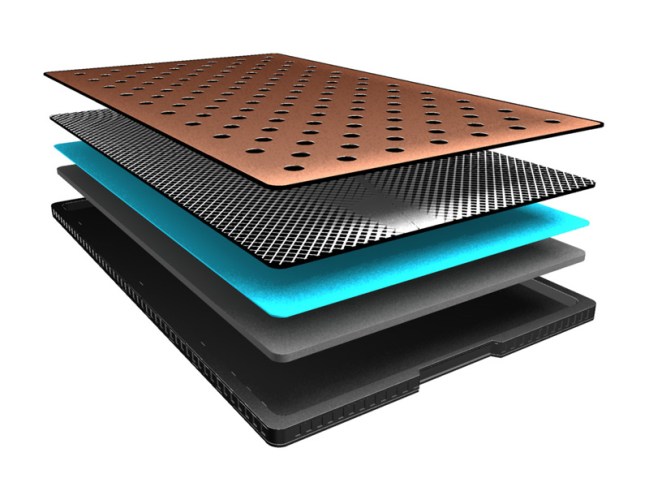

The zinc-air battery was developed by a firm called SINTEF in Norway and ReVolt was formed to market the battery. In a zinc-air battery, oxygen from room air is used to generate current. The air is used as an electrode and the battery contains an electrolyte and a zinc electrode in a casing that is porous and allows air inside. The zinc-air battery is much safer than lithium-ion batteries because there are no volatile materials inside the battery that could possibly catch fire.

The zinc-air battery produces electricity when the air electrode is discharged with the help of catalysts producing hydroxyl ions in the aqueous electrode. The zinc electrode then gets oxidized and releases electrons to form an electric current. When the battery is recharged, the process happens in reverse and oxygen is released into the air electrode.

The challenge for the researchers was to devise a method where the air electrolyte wasn’t deactivated in the recharging cycle to the point where the oxidation reaction slowed or stopped. The slowing or stopping of the oxidation reaction reduced the number of times that the zinc-air battery could be recharged.

Physorg reports that prototypes of the zinc-air battery have been tested through more than a hundred charge and discharge cycles. ReVolt hopes to increase the number of charge and discharge cycles to the 300 to 500 range. That number would make the batteries useful for cell phones and other electronic items that are recharged frequently.

The zinc-air batteries ReVolt is working on are also being developed for future use in electric vehicles. Before that point can be reached the batteries have to reach the point of being able to withstand up to 10,000 charge cycles.