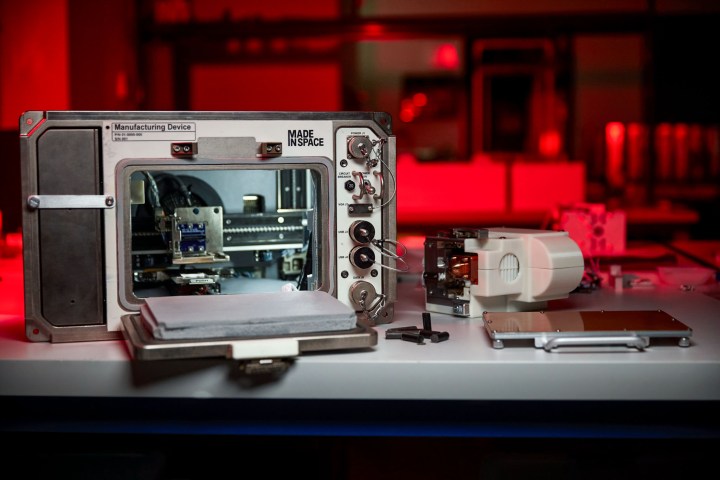

When a Northrop Grumman Cygnus cargo spacecraft arrived at the International Space Station (ISS) this week, it carried a very special piece of equipment from Earth: A 3D printer that uses moon dust to make solid material.

NASA is testing out the printing system from company Redwire for use in its upcoming Artemis moon missions, hoping to make use of the moon’s dusty soil (technically known as regolith) as raw material for printing. The idea is to use readily available materials on the moon to make what is required instead of having to haul lots of heavy equipment all the way from Earth.

Engineers have been considering how to 3D print using moon regolith for some time and have demonstrated the process on Earth. But sending a 3D printer into the microgravity environment of the ISS for testing is a big new step in getting the technology ready to use. The researchers want to know whether printing works without gravity and what the strength of the printed material will be.

The printer works using moon simulant — that is, a human-made compound of chemically similar material to moon regolith — because real samples from the moon are so precious and rare. But the simulant should be close enough to the real lunar material that it can be used to test the 3D printing hardware. The stimulant is used as feedstock, being processed and fed into the printer to be printed into useful parts and shapes.

Redwire says that as well as being used for small fixtures and fittings, this approach could eventually be used to print larger and more complex parts, such as landing pads, foundations, roads, and even lunar habitats for the astronauts to live inside.

And the effects could go beyond Earth’s gravity, too. NASA says that it is developing the technology with the hope it could eventually be used on other planets, such as for crewed missions to Mars, which could make use of the dusty Martian soil to 3D-print whole structures.