A new cycling helmet that recently launched on Kickstarter is promising to be quite a revolution for cyclists. The helmet uses 3D-printed parts in its manufacturing process to create a product that is reportedly safer, more comfortable, and offers a higher level of ventilation while remaining versatile enough for both mountain bikers and road cyclists to wear.

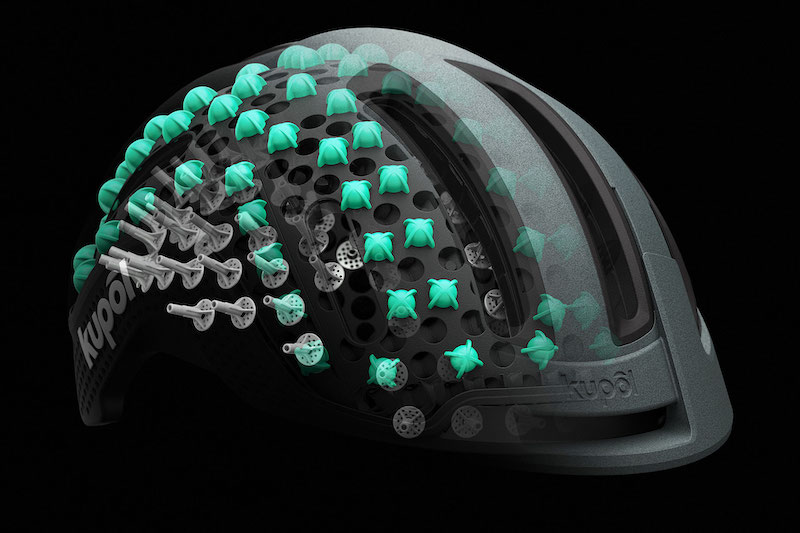

The designers of the Kupol helmet were looking for ways to improve traditional bike helmets without sacrificing performance or comfort in any way. They hit on the idea of using 3D-printed parts to create what they call the Kollide Safety System, which consists of a soft and flexible layer that sits inside the shell of the helmet itself. This layer is able to move about independently within the shell, allowing it to absorb impact from any direction. This helps to protect a cyclist not only from the impact of a motor vehicle but when striking the ground from any direction as well.

The Kollide Safety System is made up of three independent elements, all of which work together to provide improved protection. The first of those elements is something called the Oktopus pods, which are designed to help the helmet sit comfortably on a rider’s head, while also mitigating rotational motion during a crash. Kinetic bumpers are also built into the helmet to absorb medium speed impacts, while the “3D Kore” will reportedly collapse in on itself to absorb blunt force damage. According to the designers, the result of these layers working together is greatly improved absorption of kinetic energy, which translates to fewer head injuries.

The 3D-printed helmet comes with dozens of tiny cushions along its interior that are meant to adapt to the unique shape of a rider’s head, allowing it to fit more accurately and comfortably. The Kupol’s outer shell also features an aerated design that allows air to pass through, helping to keep the wearer cooler during intense rides. Since the built-in visor can be quickly and easily removed, the helmet can be adapted for use both on the trail and the road.

The Kupol team is hoping to raise about $76,000 to get the helmet into production and as of this writing, it is a third of the way toward that goal with a few weeks left in the crowdfunding campaign. If successful, the helmet will start shipping in June 2019, with an MSRP of about $300. Early bird supporters can reserve one now for 183, although as with any Kickstarter project it helps to understand the risks involved prior to pledging your hard-earned cash.

Find out more about the Kupol helmet at the company’s official website.