Printer technology doesn’t tend to change much. While form-factor designs and features come and go, the actual printing equipment – whether laser or inkjet – stays fairly constant. But printer companies are starting to make some noise on the inkjet front. HP recently made news with its speedy Office Pro X, an inkjet it says it’s faster than laser. Epson, another one of the big inkjet printer makers, thinks it’s also now time for something new. At the Labelexpo commercial printing tradeshow in Brussels, Epson unveiled its next-generation inkjet tech called PrecisionCore, a small, modular “chip” that’s based on Epson’s experience in making its Micro Piezo print-heads and micro-electromechanical systems (MEMS) manufacturing.

PrecisionCore is Epson’s largest investment in R&D and production capacity, Keith Kratzberg tells us. He’s the senior VP of sales and marketing for Epson America, the Japanese company’s U.S. division. The company has spent $300 million researching and building the new inkjet technology. Although early use of this print chip will be in the commercial printing sector, this “one print chip addresses many markets,” Kratzberg says.

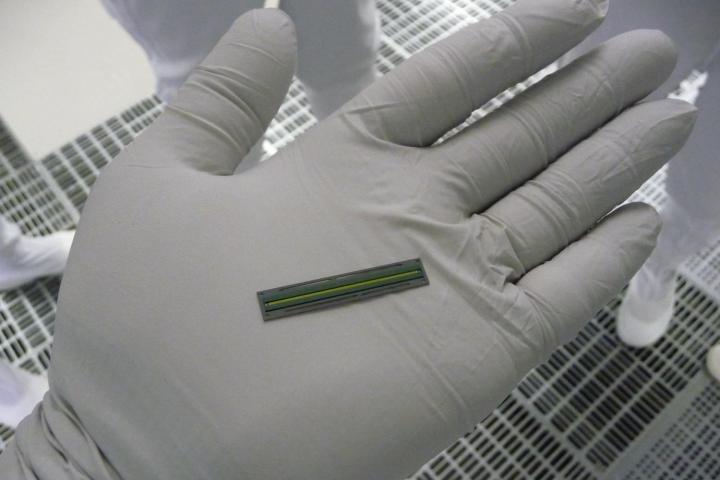

So, what does all that tech jargon mean? Micro Piezo is Epson’s brand of print-head technology that it uses in all its inkjet printers. Based on piezoelectricity, an electrical charge is applied to the print nozzle to push the ink through (versus heat used in thermal inkjet printing to boil the ink). Epson says this tech allows for ink to be dropped more precisely, and it can control the size of the drops. MEMS, in this context, refers to the manufacturing of very small devices. Combined, Epson has created a new print head that’s super small and thin (1 micron) – it looks like the size of a shaving razor blade – containing several hundred microscopic nozzles that can print up to 600 dpi resolution. “It’s a chip that prints,” Kratzberg says.

With the new print chip – which Kratzberg calls a “material science and manufacturing breakthrough” – Epson is able to place several of them (one for each color) closer together in a tight array. This allows for improved print quality and accuracy, as well as speed. One thing that Epson touts about Micro Piezo is that it’s compatible with a wide variety of inks, and because ink is controlled, it can print on very thin paper without leaking through because the drops are so small (it can also print on non-paper media like textiles). In a commercial digital press, the new technology is five-times faster than it previous technology – twice as fast in an office machine. It also allows Epson to build printing machines that are smaller.

Why does a technology built for commercial and industrial purposes matter for the consumer? Kratzberg says that the PrecisionCore technology will eventually make its way into Epson office and potentially consumer products, possibly as soon as sometime next year. We expect Epson will introduce the technology in its higher-end products, eventually rolling it out across its entire lineup.

As we’ve mentioned, printing technology hasn’t drastically changed much, but it seems to work well. So why fix something that wasn’t seemingly broken? Since printers make up a big part of Epson’s business, it makes sense it would unveil new technology to sell more products. With everything going digital, it would seem that people are printing less. But Kratzberg says the printing business as a whole is growing, and that Epson sees potential for PrecisionCore in the commercial and industrial sector, as well as office environments that want to print more in color but can’t due to cost reasons.

If you want to totally geek out on this new Epson tech, the company published a white paper online.