The size of a small microwave, the device will enable those working on board the ISS to test how well 3D printing copes with the microgravity conditions in space. NASA says the printer can produce some plastic items in just 15 minutes, and speedy output can make all the difference if there’s an emergency outside the Earth’s atmosphere.

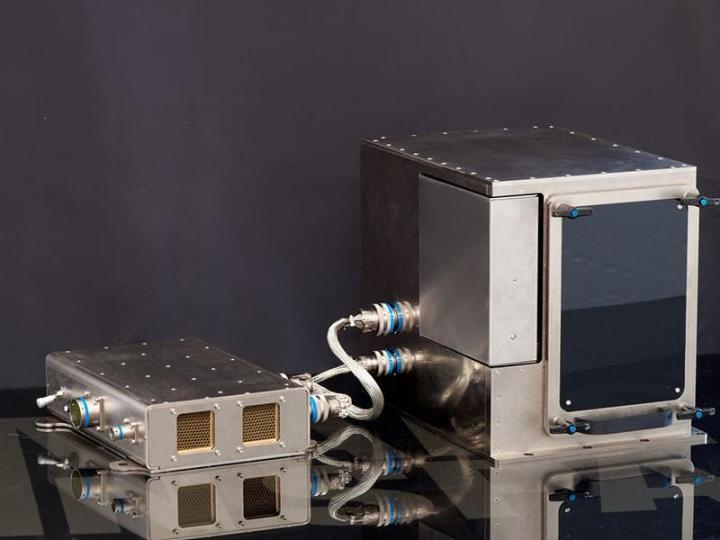

Made In Space is the company behind the Portal printer, and it’s been produced on the back of more than 30,000 hours of testing in partnership with the National Aeronautics and Space Administration. “We’re sending this bad boy off to NASA with wishes of living long and prospering,” said Aaron Kemmer, Made In Space’s co-founder.

“I think the goal in our deep space exploration, or habitation on a planetary surface, is to try and anticipate needs,” said NASA’s LaNetra Tate. “Cargo ships just can’t go make a quick run to deliver you something that you’ve run out of. People are looking at it as potentially being used for more complex components and primary structures.”

Once on the ISS, astronauts will be able to find out just how effective 3D printing in space can be. Unfortunately, bad weather initially delayed the launch of the SpaceX Dragon with the Portal on board. NASA is hoping to try again when the weather improves on Sunday.