The most significant upgrades NASA has made since the first 3D printer was installed on the ISS in November 2014 are design changes. This new version of the printer can use about 30 different materials to create finalized 3D forms in space, but Cygnus is only launching with three types of plastic for the printer to use at this time. Giving astronauts the ability to print the tools and devices they need is a huge efficiency improvement, especially compared to the alternative, which has always been sending up completed materials and objects from Earth — until now.

NASA and the US National Laboratory will be able to send digital files to the printer on the ISS, so that astronauts will be able to get their hands on whatever tools they need — be it a wrench, patch, satellite, or something entirely new and different. Shrinking the shipment size of any launch carrying materials to the ISS will also have a huge benefit. Instead of taking fully constructed objects, future launches will theoretically be able to take much smaller loads of raw materials just to keep the 3D printer stocked. “With an onboard printer, you can build things you could never deliver—like an antenna the length of a football field that supplies broadband Internet to the whole world,” said Spencer Pitman, Head of Product Strategy at Made in Space, the firm behind the zero-gravity 3D printer.

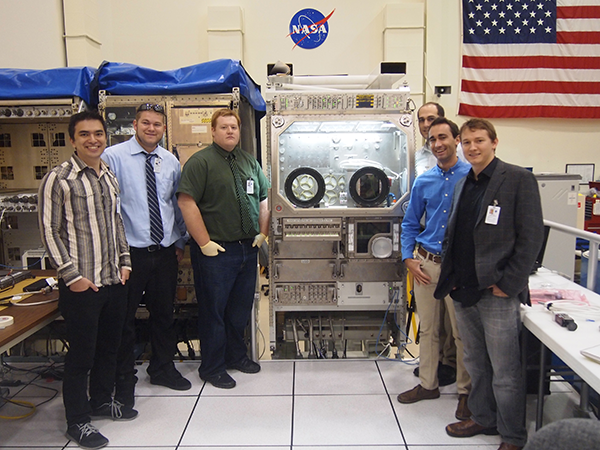

Of course, the operative words here are “zero” and “gravity”. Made in Space has been pioneering microgravity printing options, and the first 3D printer that landed in the ISS in 2014 was a more experimental version of the new edition launching today. But with a full manufacturing facility on the ISS, it will be much easier for Earth-based researchers, scientists, and inventors to test their products and ideas in total microgravity. Drop towers and parabolic flight provide a limited experience of null-g for Earthlings, but now, for anywhere between $6,000 and $30,000, inventors will be able to have their designs printed and tested directly on the ISS.